Floatable FeS-lignin hydrogel nano composite material, preparation method and application thereof

A nanocomposite material and hydrogel technology, which is applied in the field of floating FeS-lignin hydrogel nanocomposite materials, can solve problems such as difficult recycling and easy agglomeration, and achieve firm fixation, uniform nanoparticles, and complete removal of heavy metals Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Take calcium lignosulfonate (number-average molecular weight 10000, purchased from Macklin) to prepare an aqueous solution with a solid content of 10%, and prepare sodium alginate (1% viscosity: 5000mPa.s, purchased from Macklin, article number S875036) Aqueous solutions with a solid content of 5% were mechanically stirred until completely dissolved. Mix the above two completely dissolved solutions according to the volume ratio of calcium lignosulfonate solution: sodium alginate solution is 1:1, and mechanically stir until the mixture is uniform;

[0054] (2) Slowly drop the homogeneously mixed liquid in step (1) into a 1mol / L ferrous sulfate solution with a dropping funnel to form a pellet, and the solution is protected by nitrogen gas, continuously stirred and soaked for 6 hours, and freeze-dried for 18 hours;

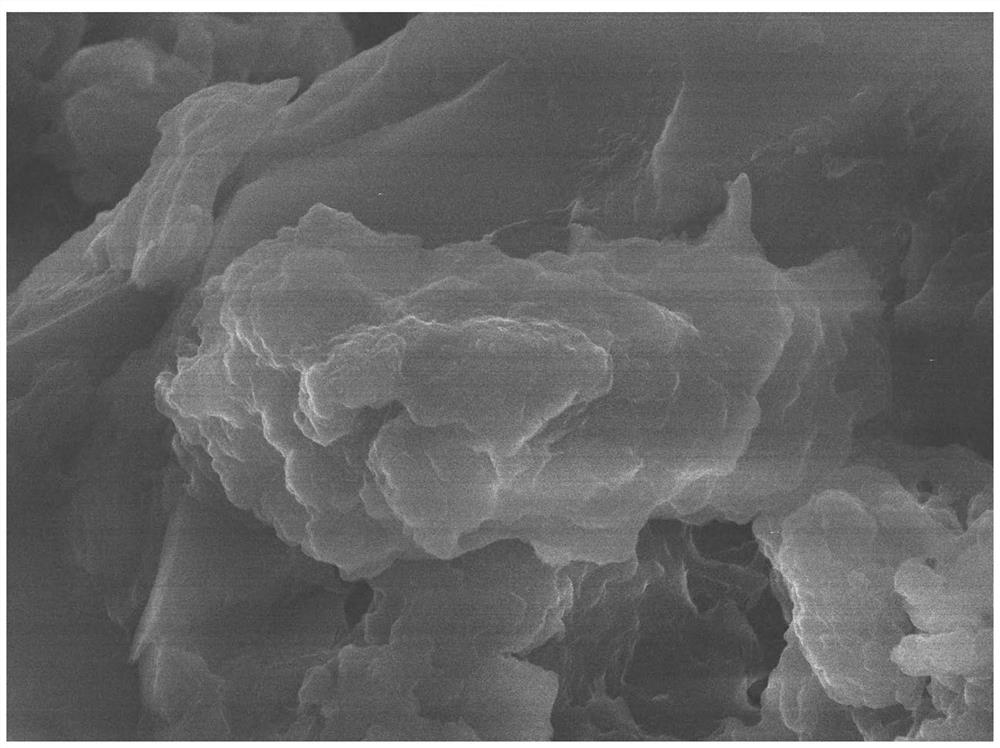

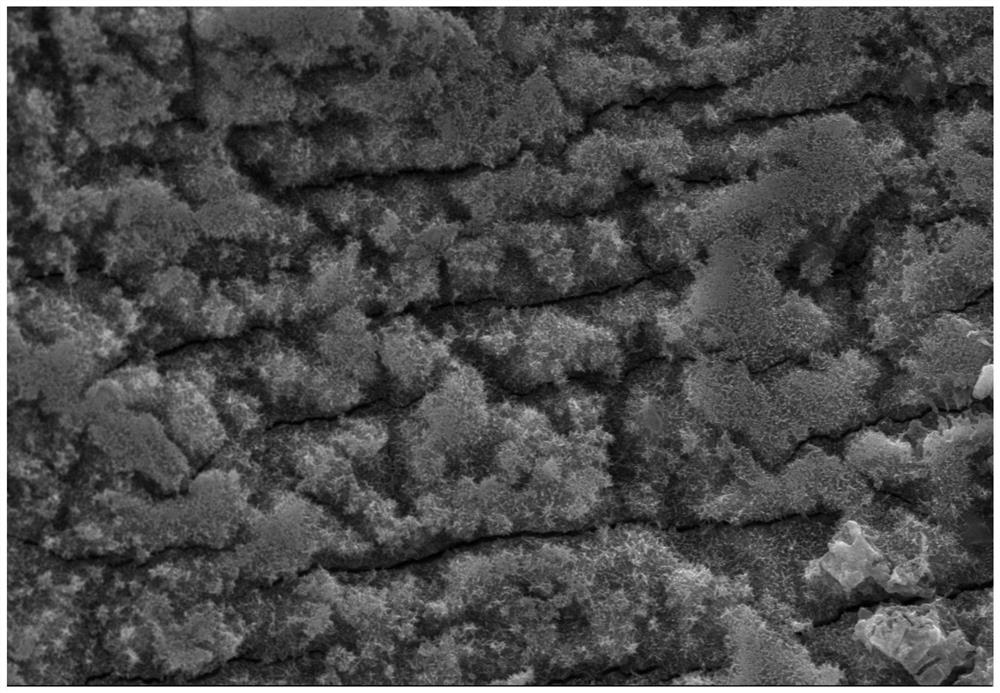

[0055] (3) Soak the freeze-dried pellets obtained in step (2) in 0.1 mol / L sodium sulfide solution for 2 hours, protect the solution with nitrogen gas, st...

Embodiment 2

[0057] (1) Get calcium lignosulfonate (number-average molecular weight 8000, purchased from Macklin) to prepare an aqueous solution with a solid content of 20%, and take sodium alginate (1% viscosity: 5000mPa.s, purchased from Macklin) to prepare a solid content of 2 % aqueous solution, respectively, mechanically stirred until completely dissolved. Mix the above two completely dissolved solutions according to the volume ratio of calcium lignosulfonate solution:sodium alginate solution is 1:0.5, and mechanically stir until the mixture is uniform;

[0058] (2) Slowly drop the homogeneously mixed liquid in step (1) into 2mol / L ferrous chloride solution with a dropping funnel to form pellets, the solution is protected by nitrogen gas, continuously stirred and soaked for 12h, and freeze-dried for 24h;

[0059] (3) Soak the freeze-dried pellets obtained in step (2) in a 0.5 mol / L sodium sulfide solution for 3 hours, protect the solution with nitrogen gas, stir continuously, and free...

Embodiment 3

[0061] (1) Take calcium lignosulfonate (number average molecular weight 5000, purchased from Macklin) to prepare an aqueous solution with a solid content of 15%, and take sodium alginate (1% viscosity: 5000mPa.s, purchased from Macklin) to prepare an aqueous solution with a solid content of 3 % aqueous solution, respectively, mechanically stirred until completely dissolved. Mix the above two completely dissolved solutions according to the volume ratio of calcium lignosulfonate solution: sodium alginate solution is 1:0.1, and mechanically stir until the mixture is uniform;

[0062] (2) Slowly drop the homogeneously mixed liquid in step (1) into 1.5mol / L ferrous nitrate solution with a dropping funnel to form pellets, the solution is protected by nitrogen gas, continuously stirred and soaked for 10 hours, and freeze-dried for 12 hours;

[0063] (3) Soak the freeze-dried pellets obtained in step (2) in a 1 mol / L sodium sulfide solution for 1 hour, pass through the solution under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com