Dielectric waveguide filter

A dielectric waveguide and filter technology, which is applied in the field of dielectric waveguide filters, can solve problems such as the fracture of the isolation channel and reduce the overall structural strength of the dielectric waveguide filter, so as to improve the use effect, strong integrity, and improve the overall structural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

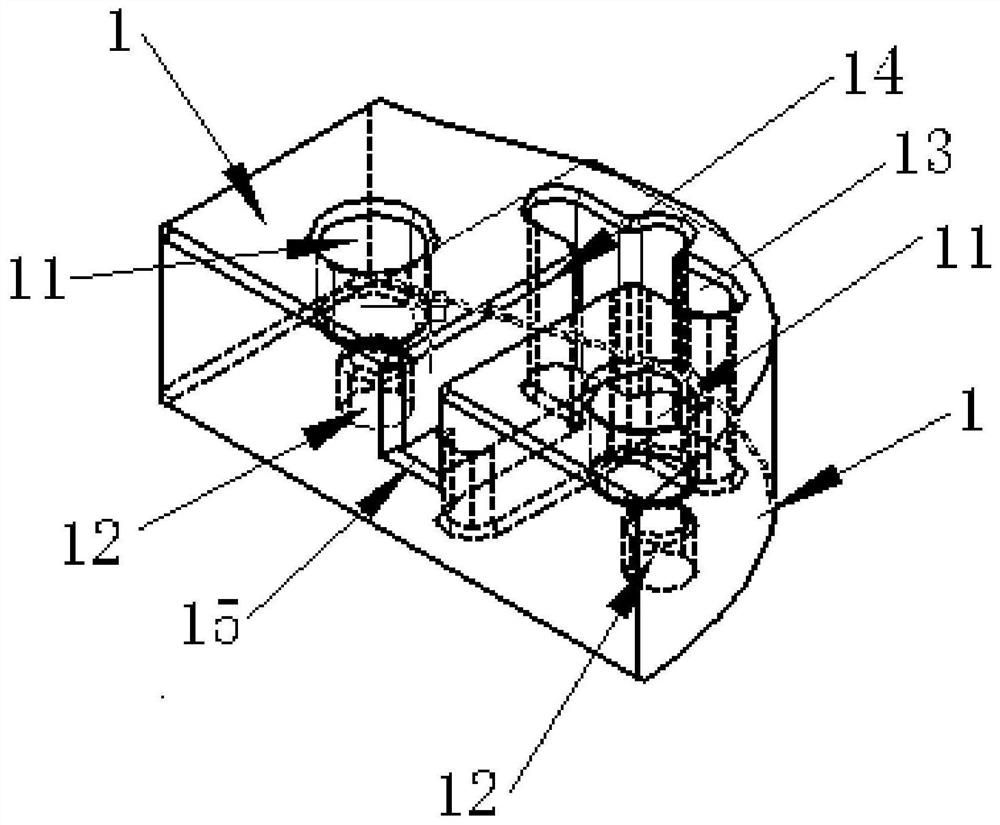

[0018] Such as figure 1 As shown, the dielectric waveguide filter of the present invention includes a ceramic body, and the ceramic body includes a window surface and a feeding blind hole surface oppositely arranged, that is, the window surface is the top surface of the ceramic body, and the feeding blind hole surface is a ceramic body The bottom surface of the ceramic body includes two dielectric waveguide feeding cavities 1, and the dielectric waveguide feeding cavity 1 is provided with a tuning blind hole 11 and an input-output coupling blind hole 12, and the opening of the tuning blind hole 11 is located on the window surface, and the input The orifice of the output coupling blind hole 12 is located on the feeding blind hole surface, and an isolation structure is arranged between the two input and output coupling blind holes 12. The isolati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com