Lithium-sulfur battery

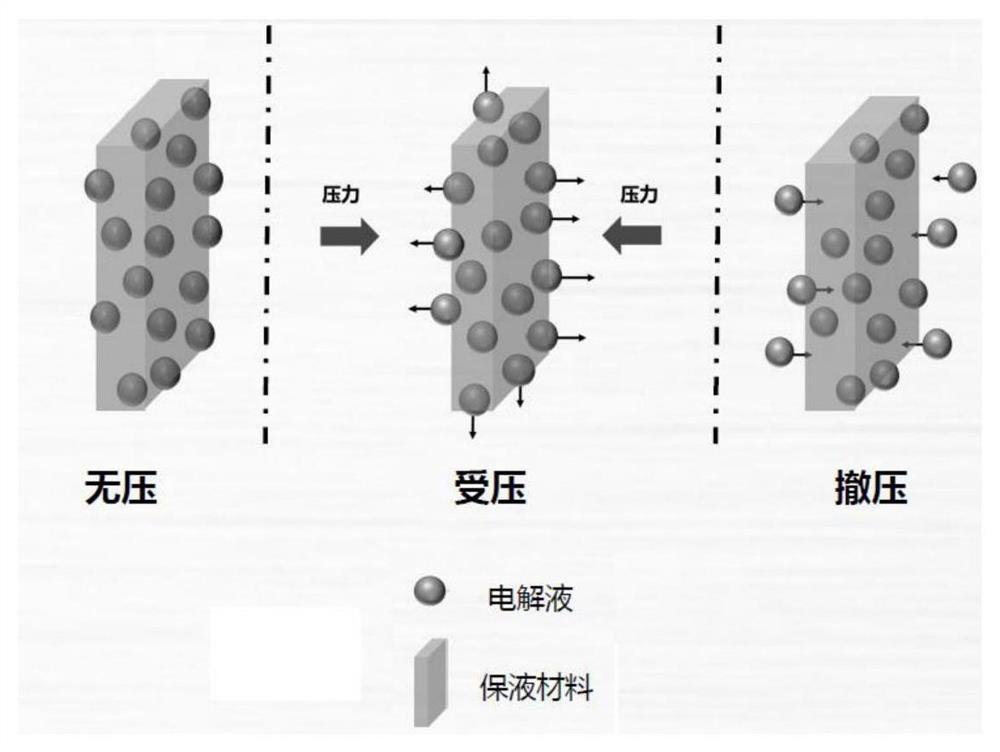

A lithium-sulfur battery, sulfur-based technology, applied in lithium batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of low specific capacity, large amount of dissolved, and too late to convert sulfur intermediate products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]Mix sulfur / carbon cathode material, conductive agent (SP) and liquid retaining material (PVDF+PMMA, PVDF:PMMA (mass ratio)=70:30) in tetrahydrofuran according to 90:2:8, and then add the above The total mass of materials (excluding solvent) is 0.5 wt% ammonium bicarbonate (pore forming agent), and all the above materials are mixed and stirred for 0.5 h at 20° C. to obtain positive electrode slurry. The slurry was coated on an aluminum foil, and dried in vacuum at 60° C. for 12 hours to obtain a porous lithium-sulfur battery positive electrode Z-1.

[0027] The obtained positive electrode Z-1 was punched into a 60×75mm positive electrode sheet, and a 200 μm thick 65×80mm lithium strip was used as the negative electrode. The diaphragm was selected from celgard2400 diaphragm, and the electrolyte was 1M LiTFSI dissolved in DOL / DME=1:1(V / V), electrolyte and active sulfur mass ratio E / S=7:1 (liquid sulfur ratio, "liquid sulfur ratio" described in embodiment 1-7 refers to the ...

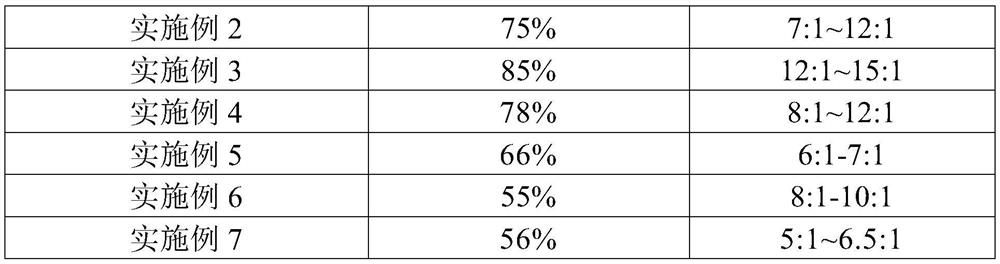

Embodiment 2

[0029] Sulfur / carbon cathode material, conductive agent (SP) and liquid retaining material (PEO+PMMA, PEO:PMMA (mass ratio)=50:50) according to 70:10:20, in dimethylformamide (DMF) After uniform mixing, ammonium bicarbonate (pore forming agent) accounting for 1 wt% of the total mass of the above materials (without solvent) was added, and all the above materials were mixed and stirred at 40°C for 4 hours to obtain positive electrode slurry. The slurry was coated on an aluminum foil, and vacuum-dried at 60° C. for 36 h to obtain a porous lithium-sulfur battery positive electrode Z-2.

[0030] The obtained positive electrode Z-2 was punched into a 60×75mm positive electrode sheet, and a 200 μm thick 65×80mm lithium strip was used as the negative electrode. The diaphragm was selected from celgard2400 diaphragm, and the electrolyte was 1M LiTFSI dissolved in DOL / DME=1:1(V / V), the mass ratio of electrolyte to active sulfur E / S=10:1 (liquid sulfur ratio), assembled into a monolithic...

Embodiment 3

[0032] Mix sulfur / carbon cathode material, conductive agent (SP) and liquid retaining material (LA133+PEG, LA133:PEG (mass ratio) = 60:40) in pure water at 80:5:15, then add The total mass of the above materials (without solvent) is 3 wt% of glucose, and at the same time, 2 wt% of the glucose mass of yeast (pore-forming agent) is added, and all the above materials are mixed and stirred at 30°C for 2 hours to obtain a fermented positive electrode slurry. The slurry was coated on an aluminum foil, and dried in vacuum at 60° C. for 24 h to obtain a porous lithium-sulfur battery positive electrode Z-3.

[0033] The obtained positive electrode Z-3 was stamped into a 60×75mm positive electrode sheet, and a 200 μm thick 65×80mm lithium strip was used as the negative electrode. The diaphragm was selected from celgard2400 diaphragm, and the electrolyte was 1M LiTFSI dissolved in DOL / DME=1:1(V / V), the mass ratio of electrolyte to active sulfur E / S=15:1, assembled into a monolithic batt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com