Fuel cell membrane electrode CCM with high-temperature-resistant and self-humidifying characteristics

A fuel cell membrane and electrode technology, used in fuel cells, battery electrodes, circuits, etc., can solve the problems of affecting battery performance, unclear impact on durability, and reducing electrode conductivity, etc., to improve proton conduction rate, easy to popularize and apply, The effect of enhancing affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

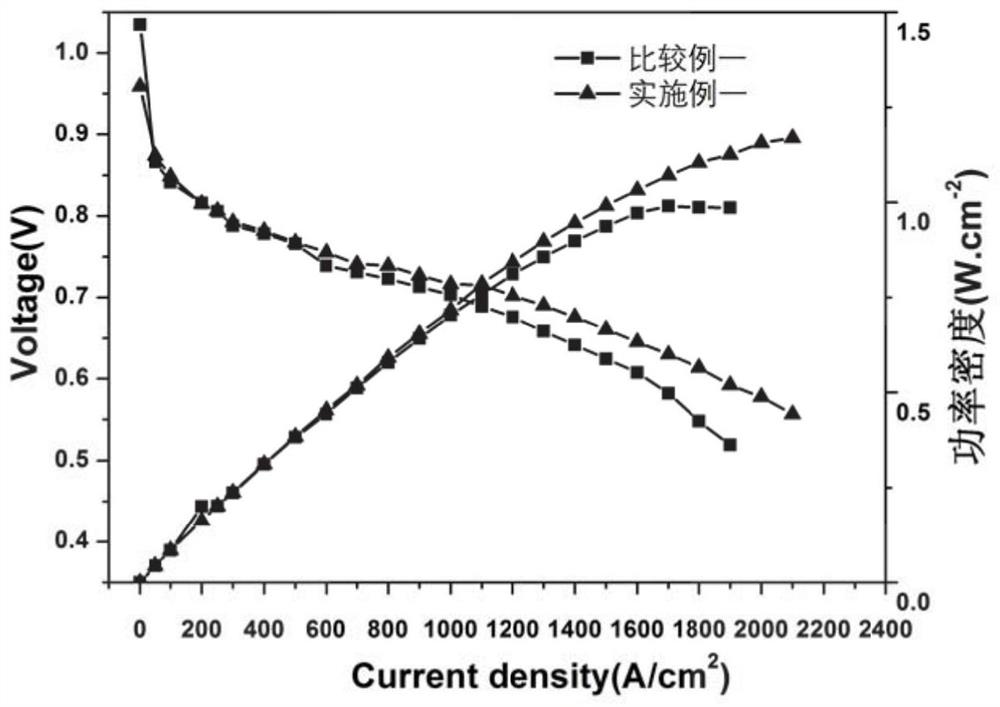

Embodiment 1

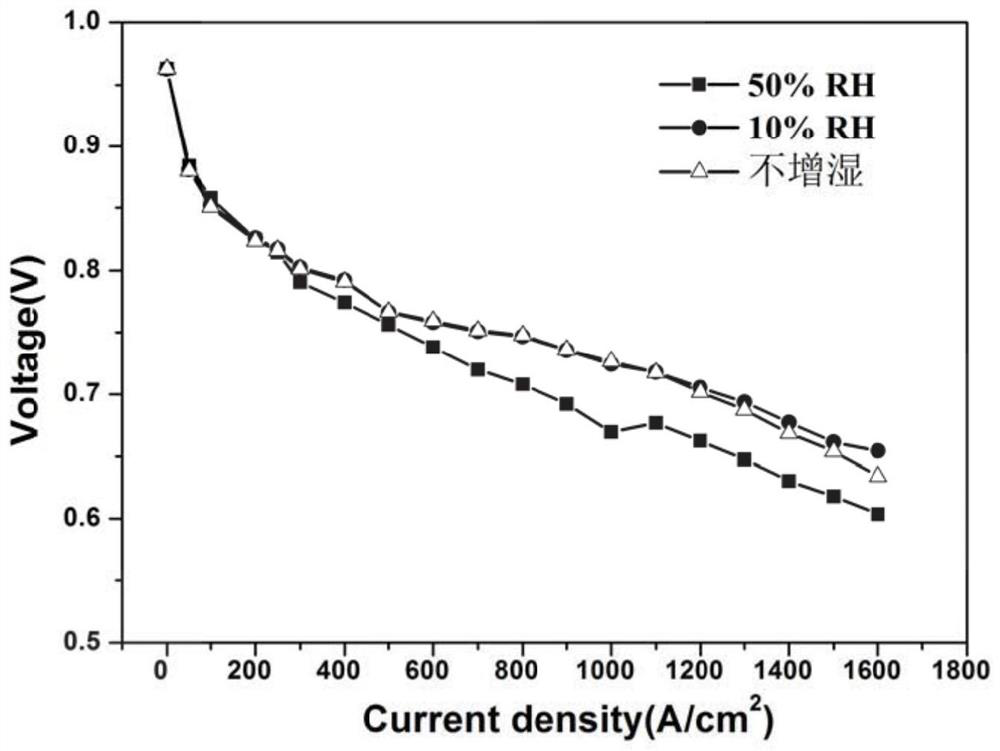

[0034] The first is slurry preparation, first determine the ratio of perfluorosulfonic acid resin to carbon in the catalyst, then add perfluorosulfonic acid resin with short side chain and low EW value to the hydrophilic catalyst, and then add low boiling point alcohol and deionized Water is added and mixed sequentially according to a certain proportion, and a uniformly dispersed slurry is obtained by ultrasonic dispersion, and the slurry is sprayed on both sides of the proton exchange membrane with high water transmission capacity and low EW value. The prepared CCM, the gas diffusion layer, and the polyester frame are heated and pressed to form an MEA.

[0035] The mass ratio of the mass of the perfluorosulfonic acid resin to the carbon in the catalyst is 0.85. The proton exchange membrane is a perfluorosulfonic acid proton exchange membrane with an EW value of around 800. The structure of the perfluorosulfonic acid resin is a short side chain type resin, the concentration o...

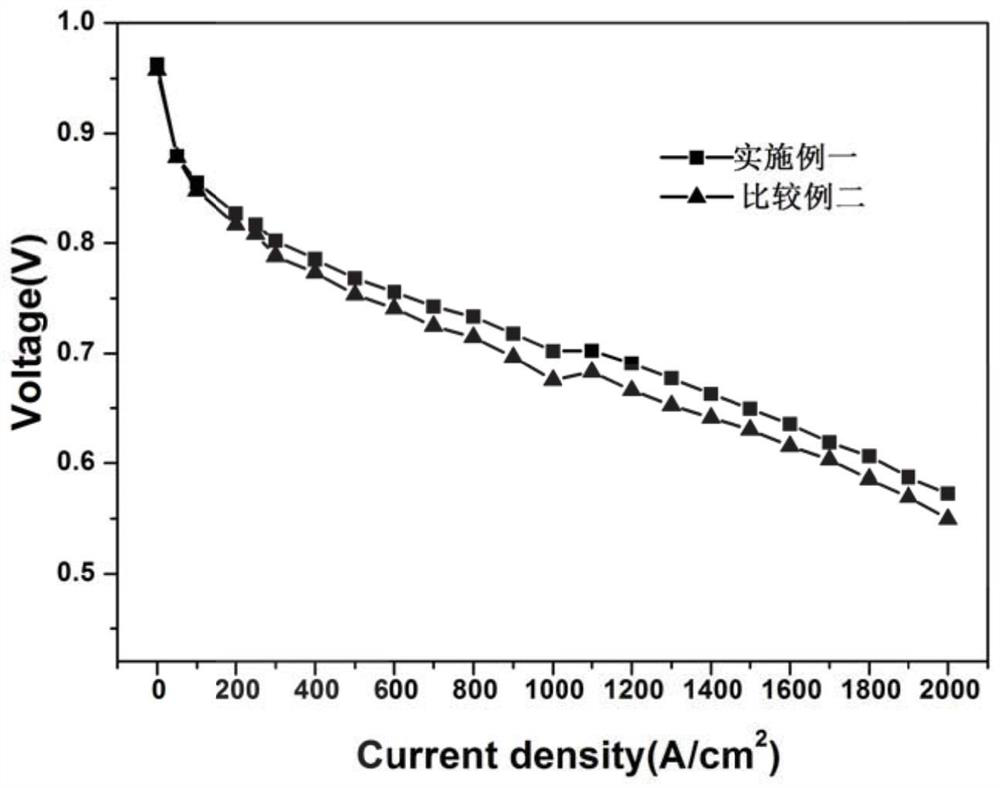

Embodiment 2-4

[0038] Adopt the perfluorosulfonic acid resin identical with embodiment 1 among the embodiment 2-4, the difference between different embodiments is that the amount of perfluorosulfonic acid resin accounts for the different percentage of carbon in the catalyzer;

Embodiment 2

[0039] The quality of embodiment 2 perfluorosulfonic acid resins and the mass ratio of carbon in the catalyzer are 0.6;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com