A kind of positive electrode slurry of lithium ion battery and its preparation method and application

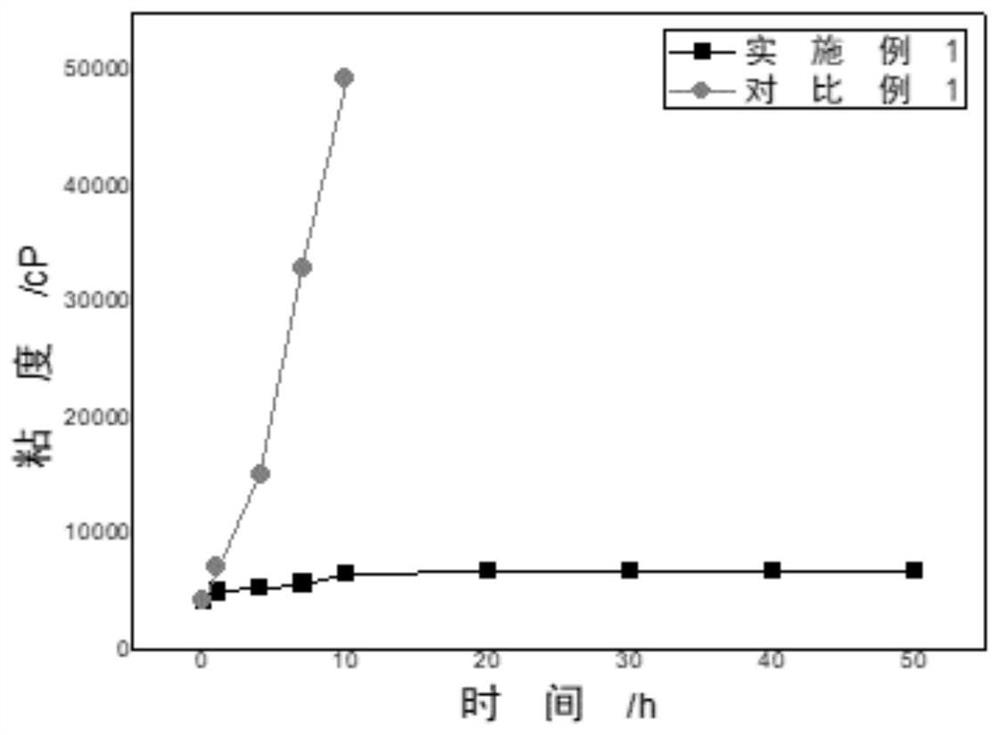

A positive electrode slurry and slurry technology, applied in the field of lithium ion battery positive electrode slurry and its preparation, can solve problems such as unfavorable application, slurry viscosity rebound, gel/jelly, etc., to prevent aggregation and sedimentation and reduce internal resistance , to ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prepare lithium-ion battery positive electrode slurry, the weight ratio of raw materials is, lithium iron phosphate: first conductive agent: second conductive agent: dispersant: binder: viscosity reducer=92:3:0.5:0.01:4:0.49 The first conductive agent is conductive carbon black, the second conductive agent is carbon nanotubes, the dispersant is polyvinylpyrrolidone, the binder is polyvinylidene fluoride, and the viscosity reducer is sodium lauroyl-N-methylglycinate, The organic solvent is N-methylpyrrolidone.

[0032] The cathode slurry of the lithium ion battery in this embodiment is prepared by the following method, and the specific operation steps of the method are as follows:

[0033] 1) Mix and stir the binder and the organic solvent to obtain glue, the stirring revolution speed is 25rpm, the rotation speed is 500rpm, the stirring time is 30min, and the stirring temperature is 25°C;

[0034] 2) Add the dispersant to the organic solvent and stir evenly, then add th...

Embodiment 2

[0042] In this embodiment, the lithium ion battery positive electrode slurry, lithium iron phosphate positive electrode active material, the first conductive agent is conductive carbon black, the second conductive agent is carbon fiber, the dispersant is polyethylene glycol, and the binder is polyvinylidene fluoride, The viscosity reducer is Triton-X and polyoxypropylene polyoxyethylene block polyether, the organic solvent is N,N dimethylformamide, and the weight ratio is: lithium iron phosphate: the first conductive agent: the second Conductive agent: dispersant: binder: viscosity reducer=96:1:0.6:0.35:2:0.05.

[0043] The cathode slurry of the lithium ion battery in this embodiment is prepared by the following method, and the specific operation steps of the method are as follows:

[0044] 1) Mix and stir the binder and the organic solvent to obtain glue, the stirring revolution speed is 35rpm, the rotation speed is 1500rpm, the stirring time is 60min, and the stirring temper...

Embodiment 3

[0053] In this embodiment, the lithium ion battery positive electrode slurry, lithium iron phosphate positive electrode active material, the first conductive agent is conductive carbon black, the second conductive agent is graphene and carbon nanotubes, and the dispersant is polyvinyl alcohol and polyethylene glycol. The binder is polyvinylidene fluoride, the viscosity reducer is BYK-1163, silicone polyether copolymer and LIB-D110, the organic solvent is N-methylpyrrolidone and N,N dimethylformamide, and the weight ratio is: phosphoric acid Lithium iron: first conductive agent: second conductive agent: dispersant: binder: viscosity reducer=92:1:2:1:2:2.

[0054] The cathode slurry of the lithium ion battery in this embodiment is prepared by the following method, and the specific operation steps of the method are as follows:

[0055] 1) Mix and stir the binder and the organic solvent to obtain glue, the stirring revolution speed is 25rpm, the rotation speed is 1000rpm, the stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com