Modification method for coating silicon-carbon composite negative electrode material interface with modified asphalt

A technology of negative electrode material and modified asphalt, which is applied in the direction of negative electrode, active material electrode, battery electrode, etc., can solve the problems of reduced Coulombic efficiency, electrode deactivation, and increase of irreversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

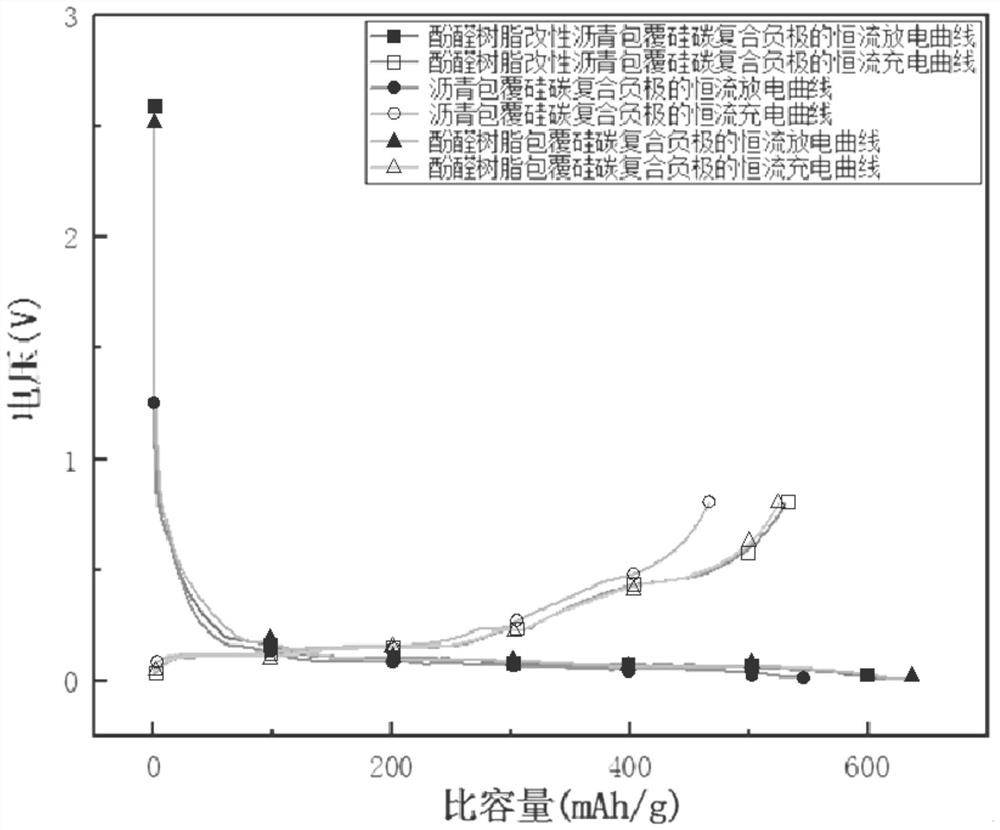

Image

Examples

Embodiment 1

[0027] Step 1. Weigh 1 portion of asphalt with a softening point of 250°C and a particle size D50 of 1.8 μm, ball mill, pulverize, and sieve; the ball mill speed is 300 rpm, the ball mill time is 5 hours, and the ball-to-material ratio is 10:1;

[0028] Step 2. Weigh 1 portion of phenolic resin with a softening point of 110°C and mix it evenly with asphalt ball mill; the ball mill speed is 300rpm, the ball mill time is 5h, and the ball-to-material ratio is 10:1;

[0029]Step 3. Put 1 part of phenolic resin pitch mixture, 1 part of D50 of 150nm nano-silicon, and 8 parts of D50 of 3 μm graphite into a ball mill for ball milling to obtain the precursor of phenolic resin modified pitch coated silicon-carbon composite negative electrode material; ball mill The rotating speed is 500rpm, the ball milling time is 10h, and the ball-to-material ratio is 15:1;

[0030] Step 4. Sinter the precursor of the phenolic resin-modified pitch-coated silicon-carbon composite negative electrode mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com