Image sequence matching system and method for visual inspection equipment

A technology of image sequence and visual inspection, which is applied in image enhancement, image analysis, image data processing, etc., can solve the problem of image binding dislocation, and achieve the effect of ensuring calibration information and image binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

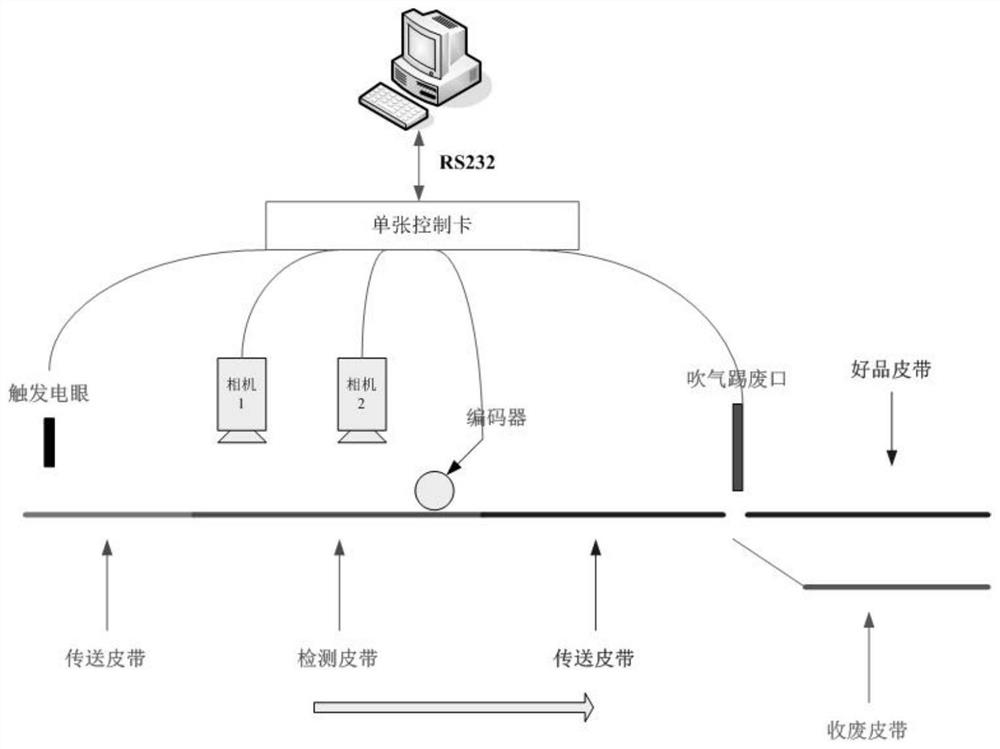

[0060] As an implementation manner, the image acquisition unit includes a code image imaging module and a light emitting module;

[0061] The light emitting module is used to illuminate the collection area and adjust the brightness of the code image collected by the code image imaging module.

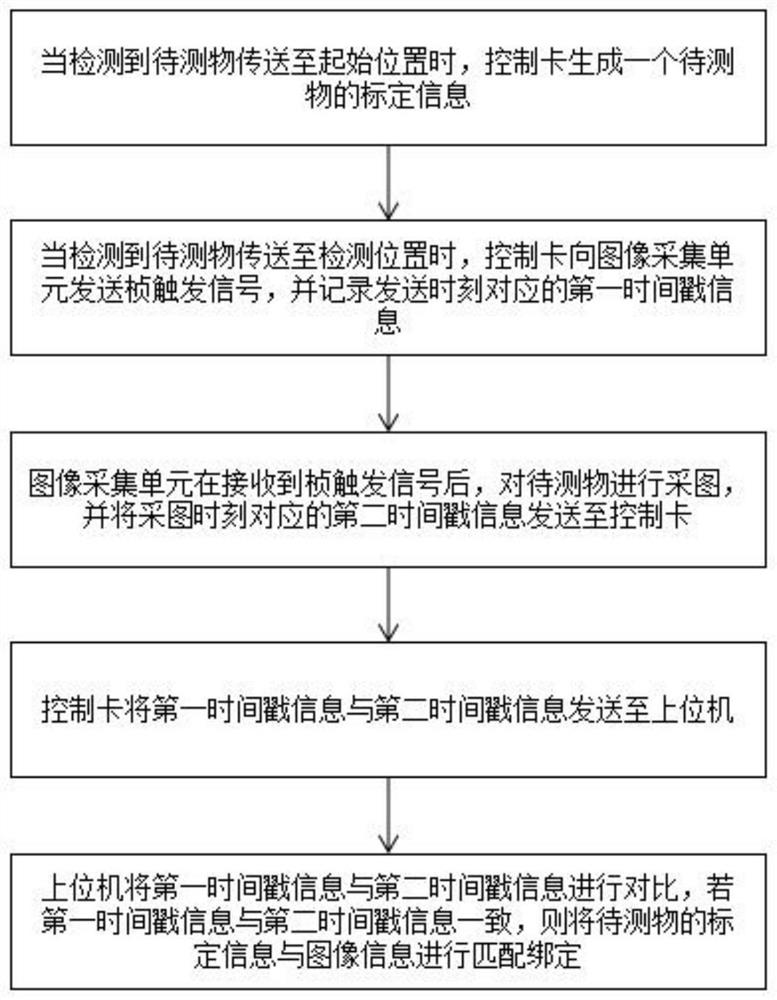

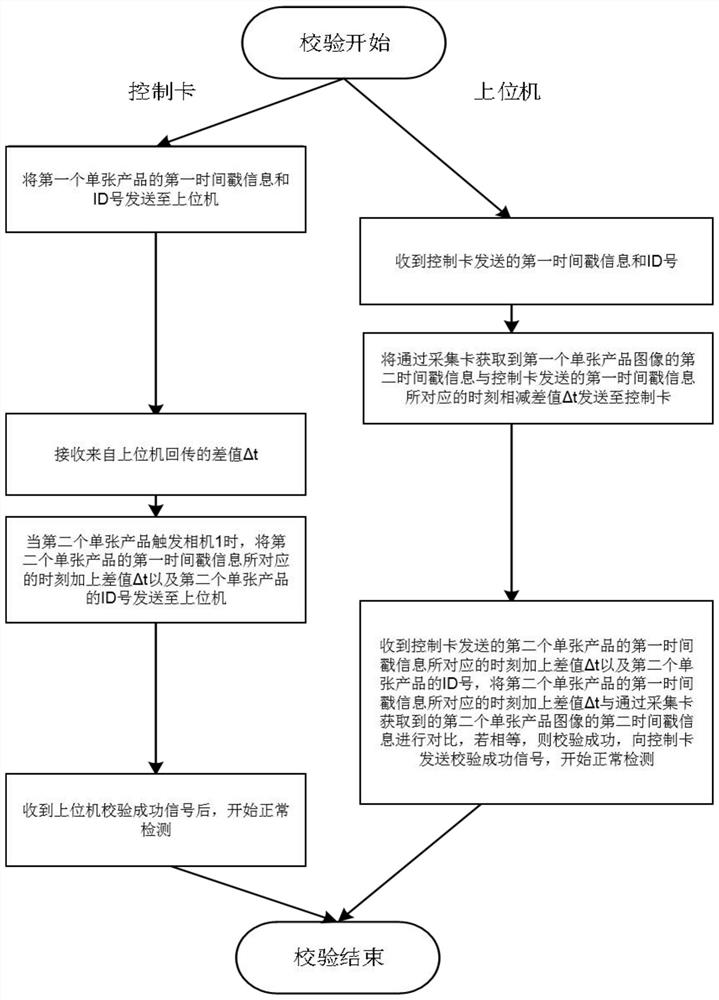

[0062] Such as figure 2 As shown, the embodiment of the present application also provides an image sequence matching method for visual inspection equipment, the method is applied to the above system, and the method includes the following steps:

[0063] When it is detected that the object under test is transferred to the initial position, the control card generates a calibration information of the object under test;

[0064] When it is detected that the object under test is transmitted to the detection position, the control card sends a frame trigger signal to the image acquisition unit, and records the first time stamp information corresponding to the sending time;

[0065] After re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com