Sealing structure suitable for high-pressure plastic inner container carbon fiber full-winding gas cylinder and application

A technology of sealing structure and winding gas cylinders, which is applied in the direction of pressure vessels, fixed-capacity gas storage tanks, and container discharge methods. It can solve problems such as complex design, low sealing reliability, and fatigue failure of gas cylinders, and achieve structural stability. , improve reliability and stability, and make the effect of simple manufacturing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the examples shown in the accompanying drawings.

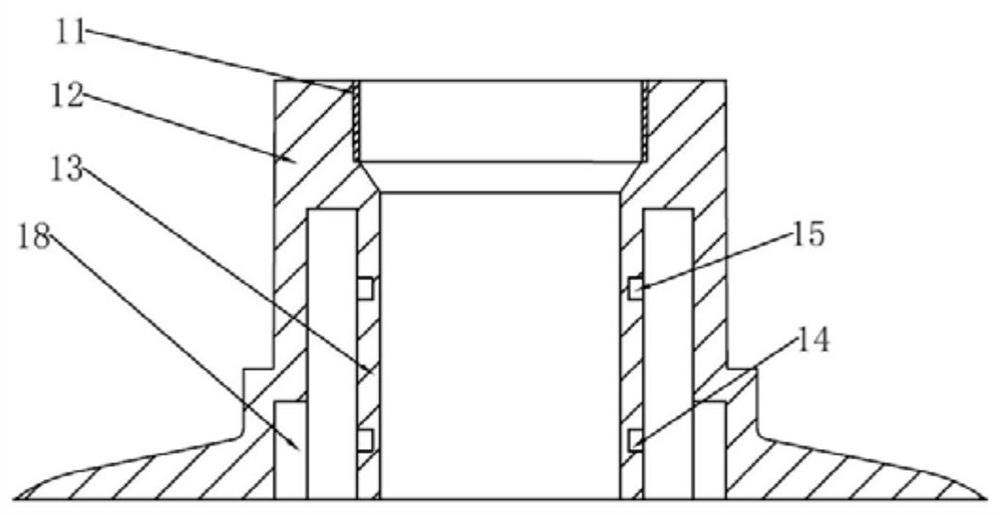

[0040] The mouth structure of a high-pressure type IV hydrogen storage bottle with a reliable and stable sealing structure according to the present invention is mainly composed of a metal bottle mouth, a plastic liner and a carbon fiber composite layer. An example of the present invention is that the nominal working pressure is 70MPa, and the water volume is the bottleneck structure of the plastic liner carbon fiber fully wound hydrogen storage cylinder of 60L.

[0041] figure 1 Shown is a schematic diagram of the mouth structure of a high-pressure plastic liner carbon fiber fully wound hydrogen storage cylinder according to an example of the present invention. The mouth of the Type IV hydrogen storage bottle includes a metal mouth 1 , a plastic liner 2 and a carbon fiber composite material layer 3 . The mouth structure of the hydrogen storage b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com