Cylinder wall thickness gradual change type cup-shaped flexible gear and harmonic gear transmission device

A gradual change and cup-shaped technology, which is applied in transmission devices, portable lifting devices, hoisting devices, etc., can solve the problems of reducing the service life of harmonic gear transmissions, damage to the cylinder body and the bottom of the cylinder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

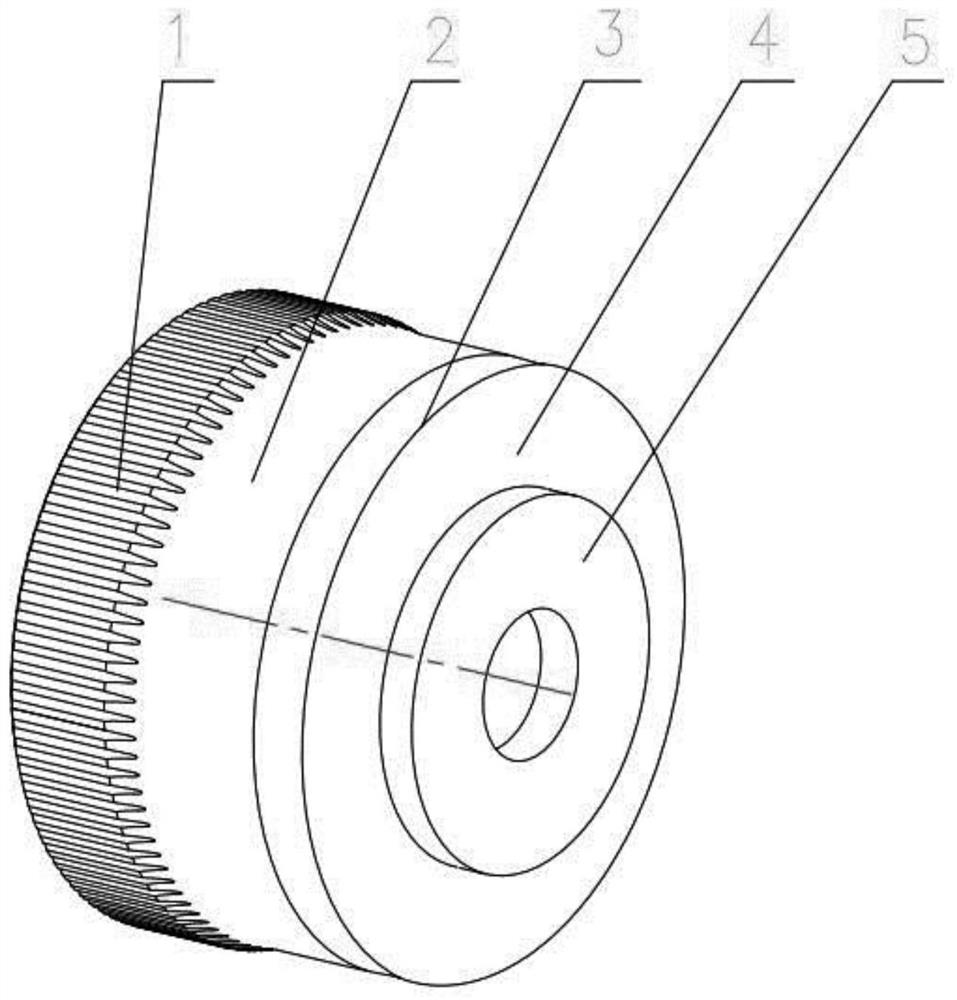

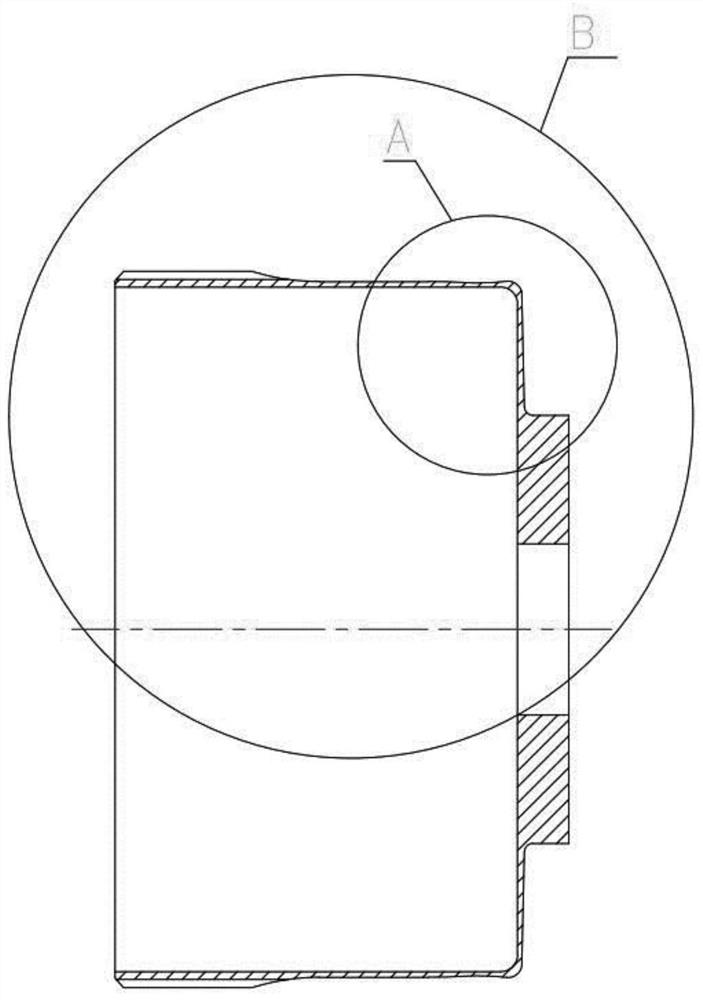

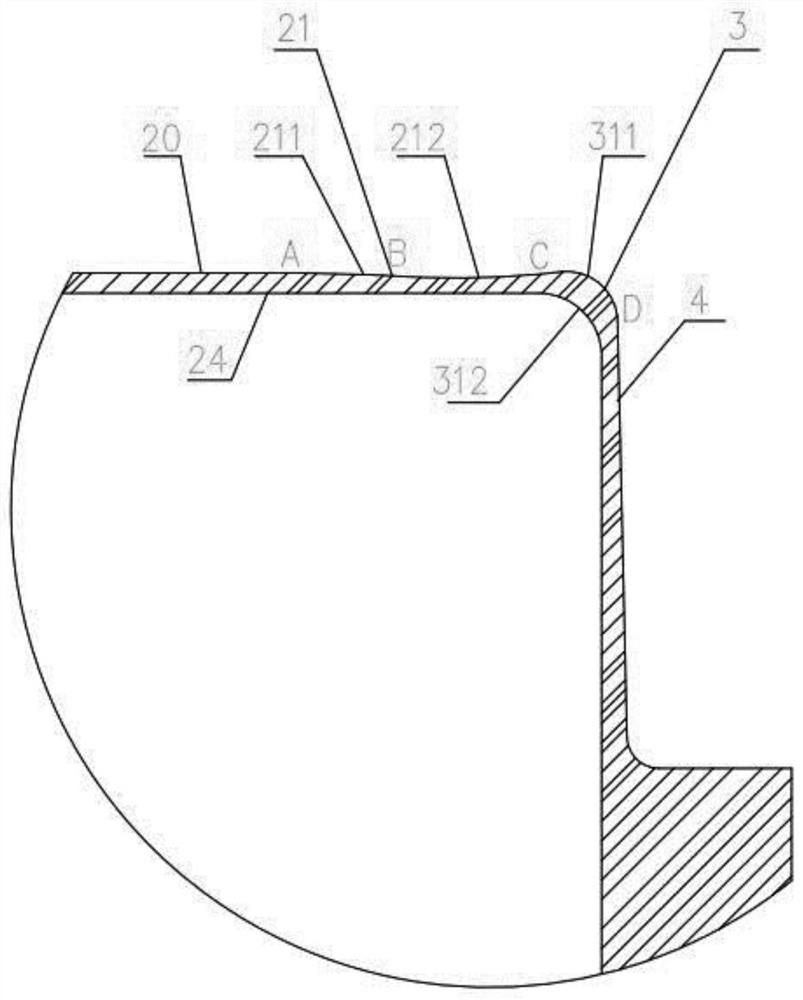

[0049] see Figure 1-Figure 4 , this embodiment provides a cup-shaped flexible spline with a cylinder wall thickness gradually changing, including a ring gear 1, a cylinder body 2, a cylinder bottom 4 and a flange 5; The wall cylinder section and the arc transition section 3, the outer wall side shape of the thin-wall cylinder section and the arc transition section 3 are formed by the first thickening curve section 21 and the second thickening curve section 31 which are tangent to each other, and the teeth Circle 1, straight cylinder section 20, thin-walled cylinder section, arc transition section 3 and cylinder bottom 4 are sequentially connected, and flange 5 is arranged on the surface of cylinder bottom 4 away from arc transition section 3; the first thickening curve The shape of the outer wall side of the section 21 is composed of a first curved arc 211 and a second curved arc 212 that are tangent to each other. The arc 212 is connected tangentially to the outer wall side...

Embodiment 2

[0070] This embodiment provides a harmonic gear transmission device, which includes the cup-shaped flexspline with cylinder wall thickness gradually changing in the above embodiment.

[0071] Compared with the prior art, the beneficial effect of the harmonic gear transmission provided by the embodiment of the present invention is the same as the beneficial effect of the cup-shaped flexible spline provided by the first embodiment above, and will not be repeated here.

[0072] Those of ordinary skill in the art can understand that all or part of the steps in the above-mentioned inventive method can be completed by instructing related hardware through a program. The above-mentioned program can be stored in a computer-readable storage medium. When the program is executed, it includes: For each step of the method in the above embodiments, the storage medium may be: ROM / RAM, magnetic disk, optical disk, memory card, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com