Formation method of lithium iron phosphate battery

A technology of lithium iron phosphate battery and formation method, which is applied in the field of lithium-ion batteries, can solve problems such as impact on battery performance, achieve the effect of improving infiltration effect, improving bulging phenomenon, and lower requirements for formation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

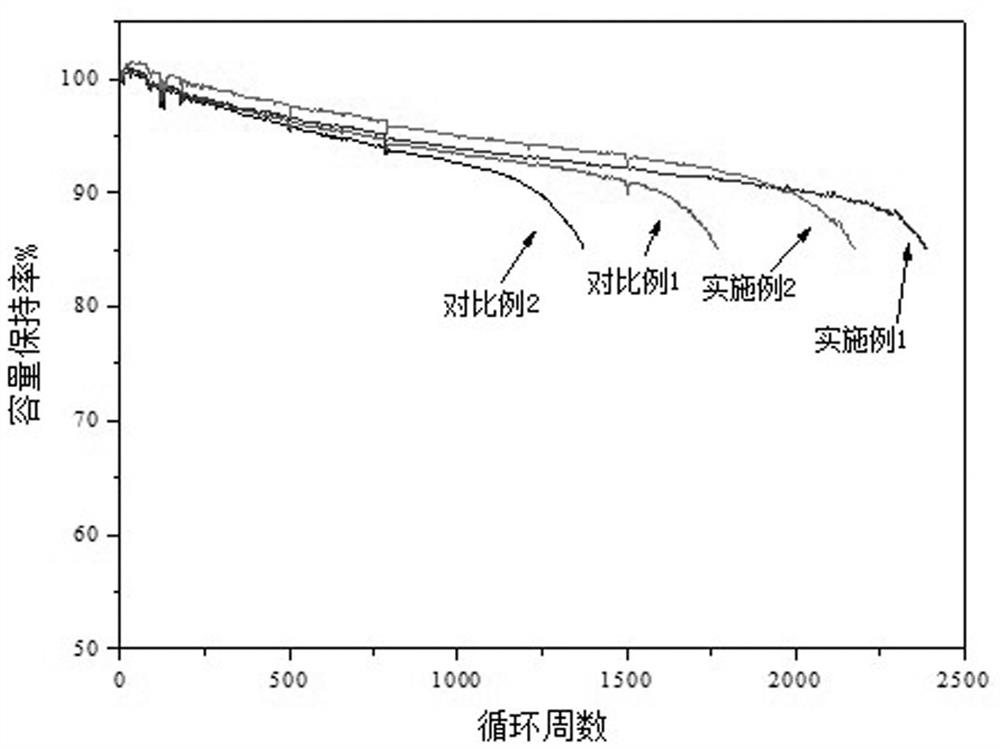

Embodiment 1

[0021] After the lithium iron phosphate battery is injected, let it stand at room temperature for 24 hours, and clamp the battery with two tempered glass plates that are about 4mm thicker than the battery body, and the tabs and air pockets are leaked out. Charge it with a current of 0.03C for 16.7h on the chemical conversion cabinet, remove the splint, put the battery air bag up, and let it stand in an oven at 45°C for 48h. After charging to 3.65V, continue to discharge to 2.5V with a current of 0.1C, charge and discharge with a current of 0.5C for a week, and finally maintain 30% of the power. Remove the battery splint, and carry out suction sealing under the condition of vacuum degree of -0.09MPa.

Embodiment 2

[0023] After the lithium iron phosphate battery is injected, let it stand at room temperature for 24 hours, and clamp the battery with two tempered glass plates that are about 4mm thicker than the battery body, and the tabs and air pockets are leaked out. First charge with 0.05C current for 10 hours on the chemical conversion cabinet, remove the splint, put the battery air bag upwards, and let it stand in a 45°C oven for 48 hours. After 3.65V, continue to discharge to 2.5V with a current of 0.3C, charge and discharge with a current of 1C for a week, and finally maintain 30% of the power. Remove the battery splint, and carry out suction sealing under the condition of vacuum degree of -0.09MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com