Tubular muffler for automobile

A muffler and tube type technology, applied in muffler devices, machines/engines, engine components, etc., can solve problems such as non-targeted noise elimination, sound wave weakening muffling effect, inability to eliminate noise, etc., to prevent water or impurities from entering The effect of pipeline and noise elimination is remarkable, and the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention. The positional relationships described in the embodiments are consistent with those shown in the accompanying drawings.

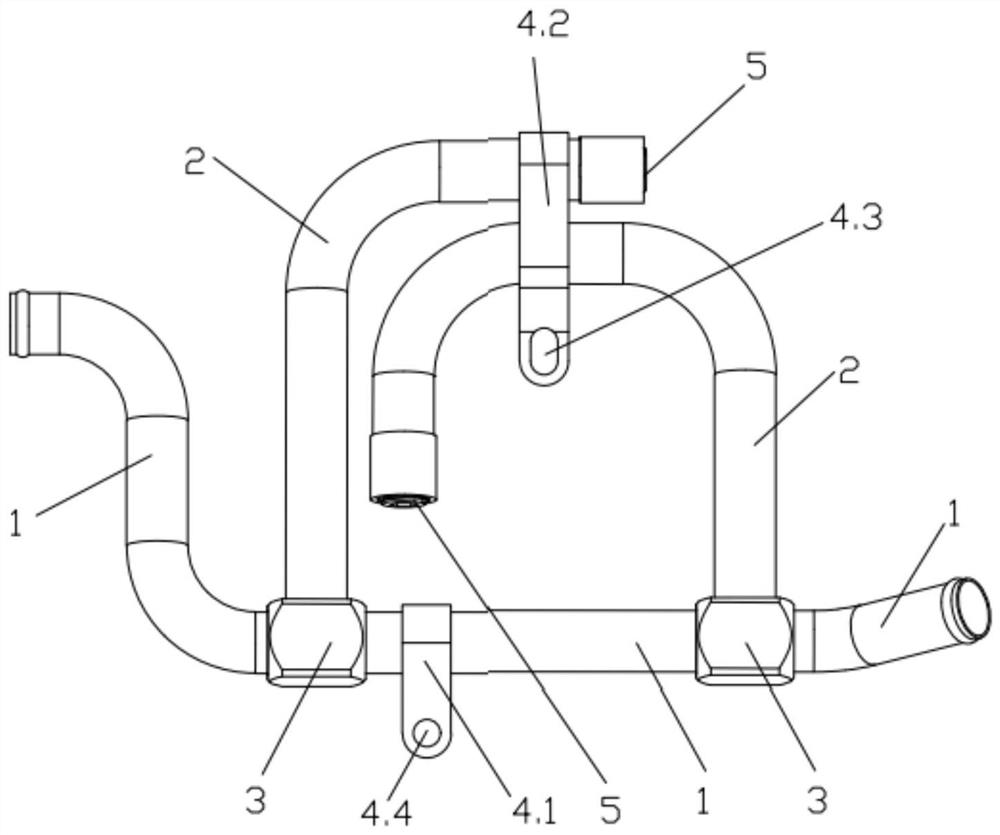

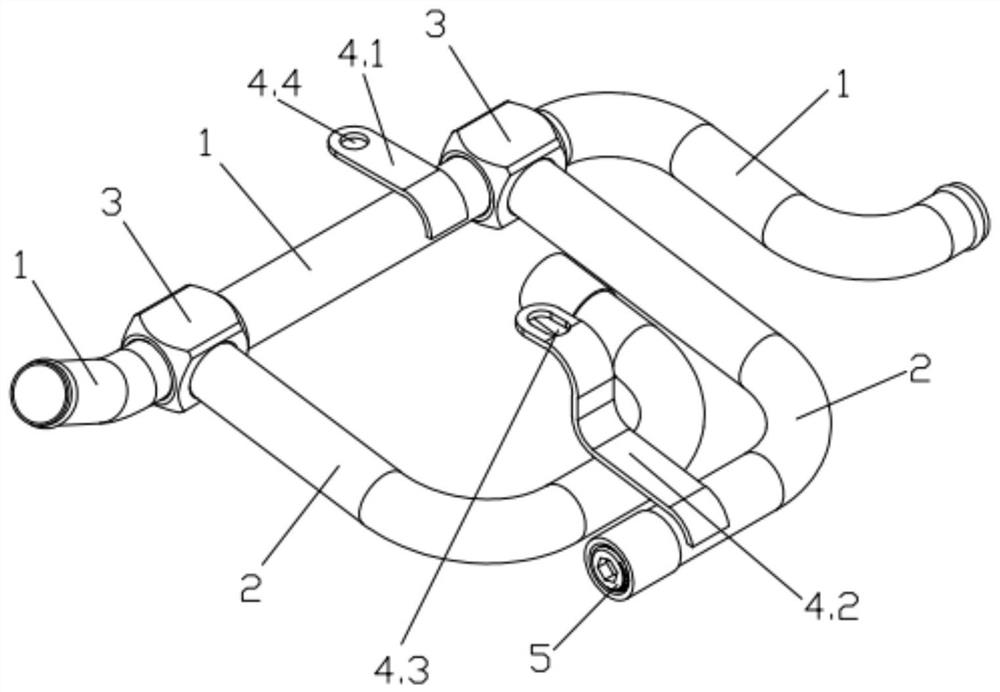

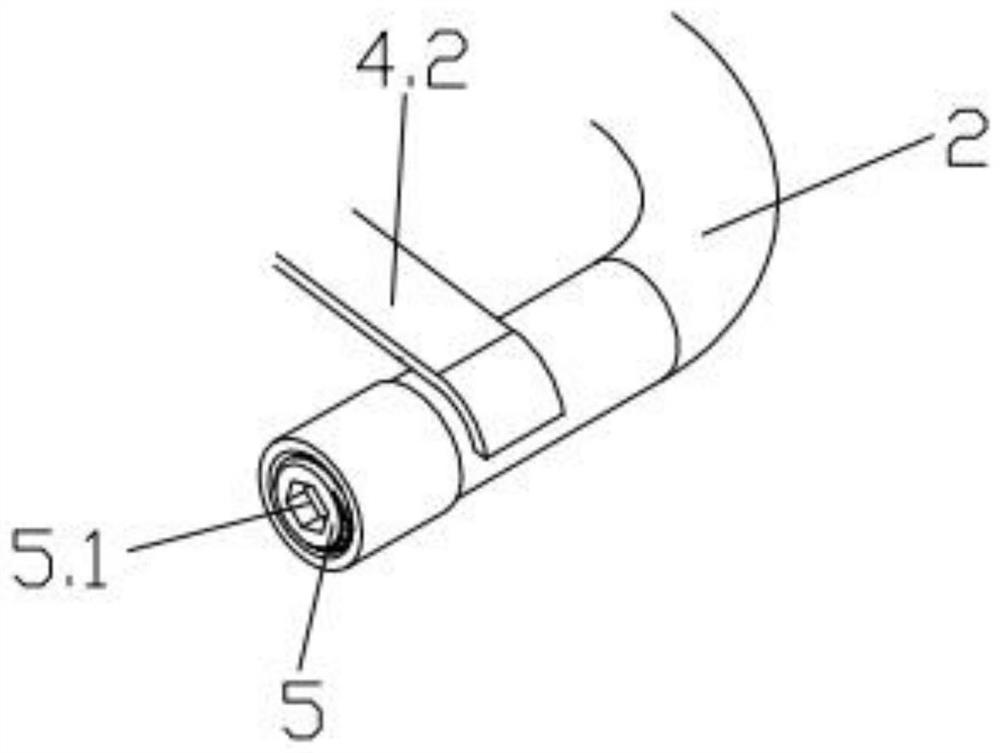

[0017] Such as figure 1 and figure 2 As shown, a tubular muffler for automobiles has two tee joints 3 welded on the vent pipe 1, two muffler pipes 2 are respectively welded on the two tee joints 3, and the ends of the muffler pipes 2 are installed There are plugs 5. Such as image 3 As shown, the middle part of the plug 5 is provided with an inner hexagonal groove 5.1, and the outer side of the plug 5 and the end of the muffler pipe 2 are provided with matching threads, and the plug 5 can be easily installed on the muffler pipe by using a hexagonal wrench ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com