Thin coal seam roadway side face construction stoping method

A thin coal seam and roadway technology, which is applied in ground mining, earthwork drilling, underground mining, etc., can solve the problems that the fully mechanized mining face area and corner coal cannot be arranged, mining cannot be carried out, and resources are idle, so as to improve working conditions and labor environment, a high degree of automation, and the effect of simplifying the mining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

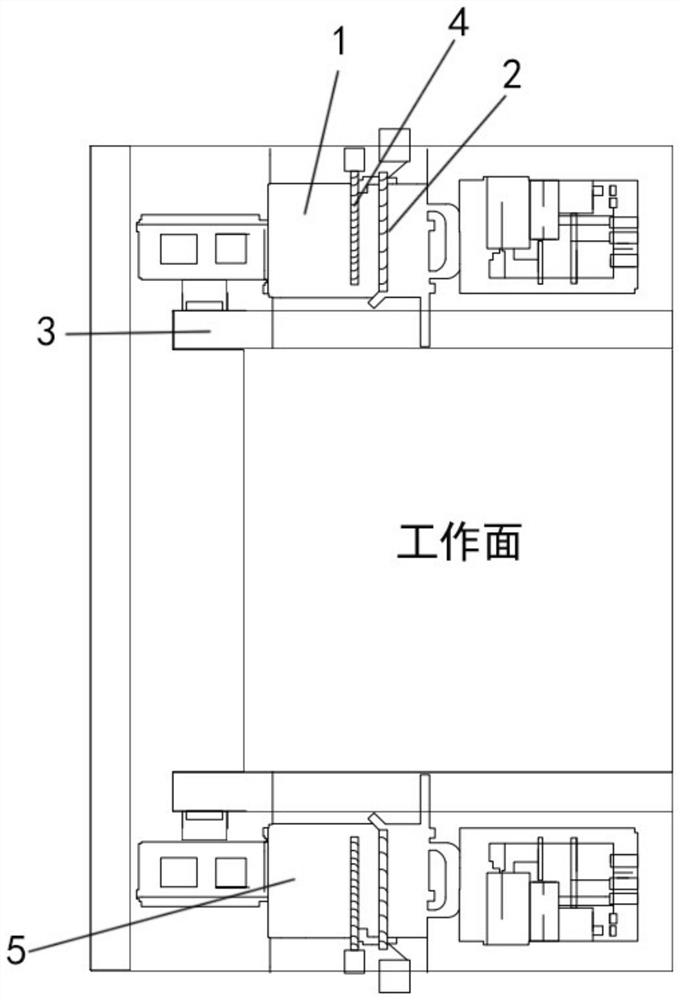

Image

Examples

Embodiment

[0042] Economic Benefit Analysis

[0043] Coal recovery benefits: the drilling speed v of the auger shearer is controlled at 1.5m / min, and the drill bit is 525mm. The recoverable coal volume per hour of the drilling rig is Q=60vπR2rK; Q is the coal recoverable volume per hour; v is the drilling speed of the coal machine controlled at 1.5m / min; R is the radius of the drill bit 0.525 / 2m; r is the bulk density of coal is 1.35 t / m3; K is the influence variable of the coal machine, the drill bit is extended and the coal machine is replaced, and the value here is 0.9; calculated according to the recovery process Q=60*1.5*3.14*(0.525 / 2)2*1.35*0.9; after The 8 o'clock shift and the 4 o'clock shift for two-hour maintenance will produce 14 hours a day. Each shearer can produce 336 tons per day. Two shearers arranged in two lanes can produce 672 tons in a round shift, and coal can be mined every month. The volume is 20,160 tons. According to the current coal price of 246 yuan / ton, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com