Rapid construction method for fire pool

A construction method and technology for fire-fighting pools, which are applied to building components, building thermal insulation materials, building types, etc., can solve the problems of inconvenient production work, affecting the operation of scenic spots, and high production costs, and achieve extended service life, strong popularization, and simple procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

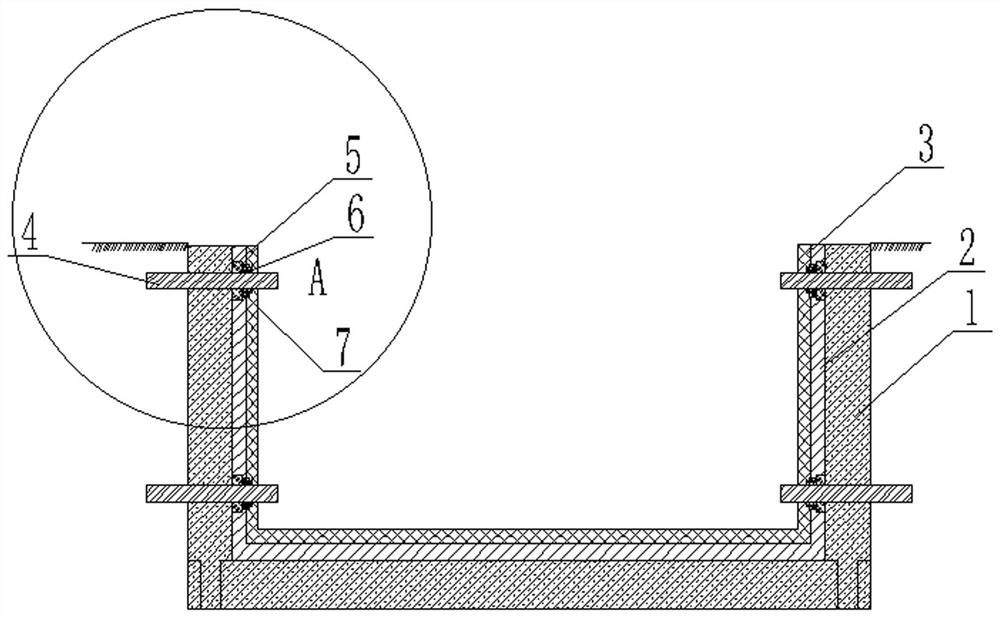

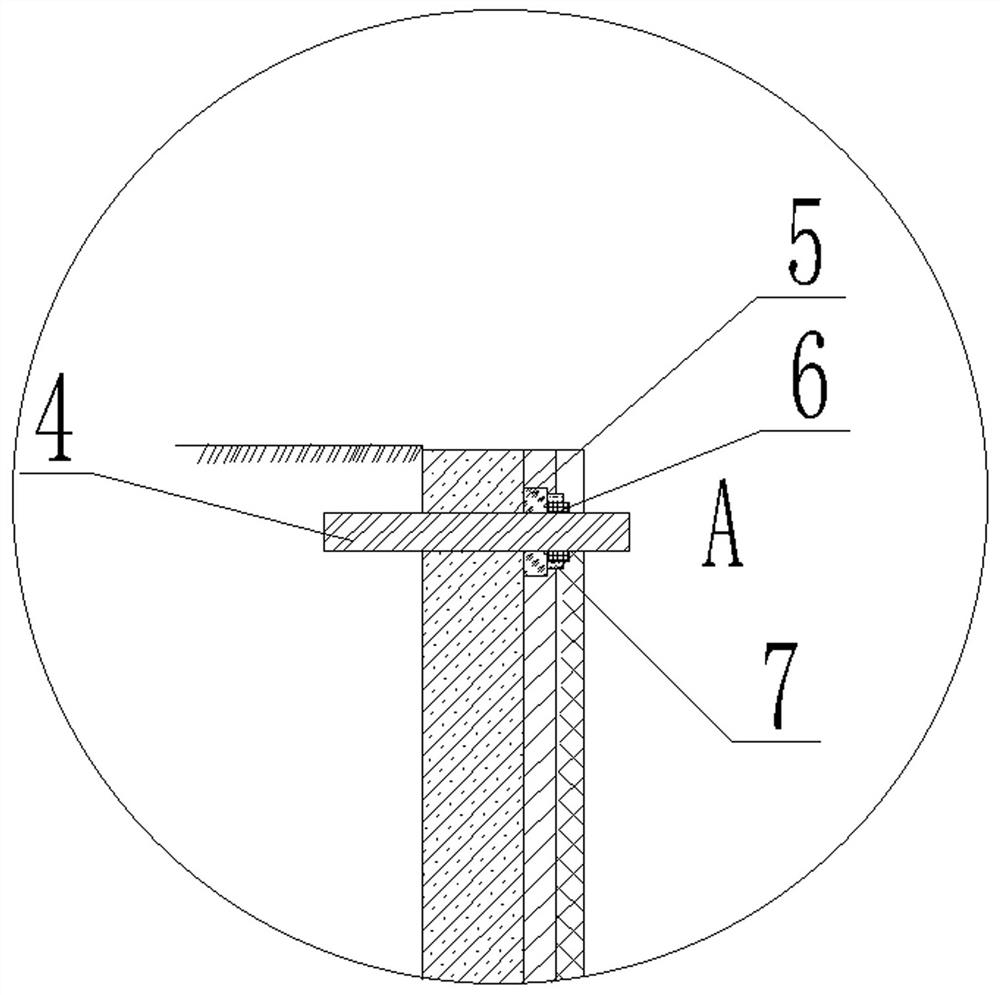

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] as attached Figure 1-2 As shown, the present embodiment provides a rapid construction method for a fire-fighting pool, which includes the following steps:

[0028] S1: Manufacture of prefabricated slabs. Prefabricated slabs are manufactured in the workshop of the factory, prestressed steel bars are pierced on the steel formwork, the prestressed steel bars are stretched according to the tension specified in the design, and temporary anchoring is performed with clamps; then non-prestressed steel bars are tied , vertical formwork pouring component concrete, vibrating and compacting, and closing. When the concrete reaches a certain strength, cut off the non-prestressed steel bars to make the prefabricated slab meet the requirements of anti-seepage, frost resistance, and strength. The prefabricated slab needs to be designed Compatible sockets and inserts;

[0029]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com