Caisson type composite shear wall underground garage and its construction method

A technology for composite shear walls and underground garages, which is applied in caisson-type composite shear wall underground garages and its construction, can solve problems that have not been studied, and achieve low transportation costs, no need for foundation pit support, and connection tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

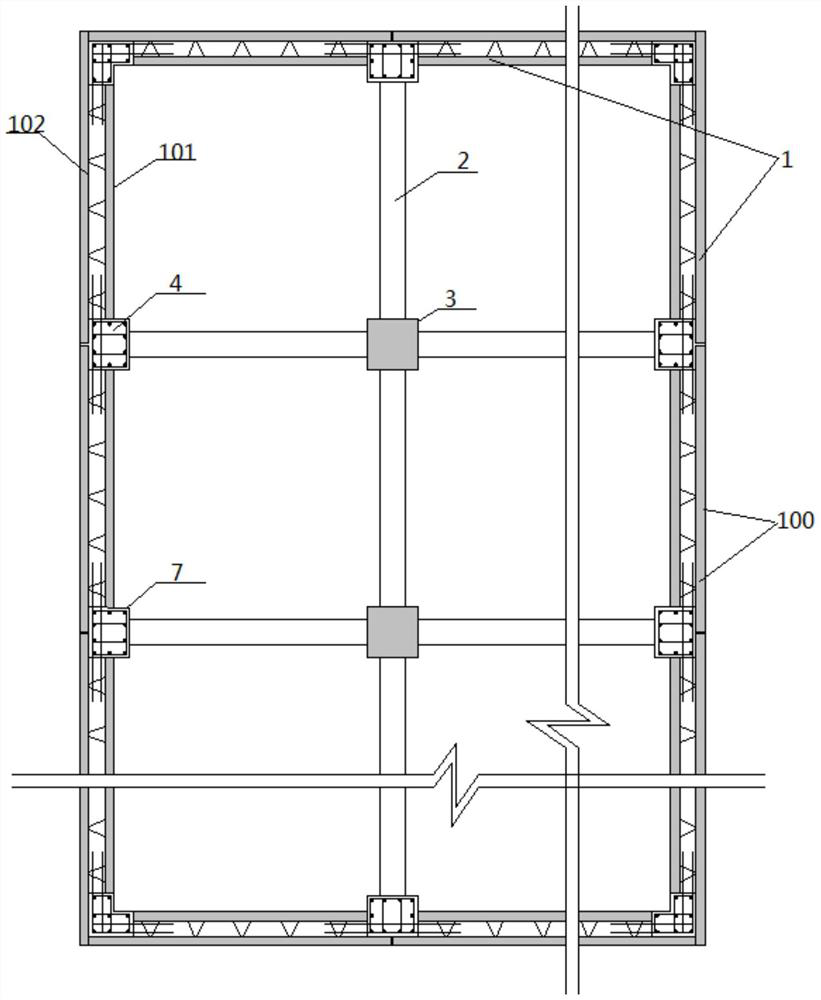

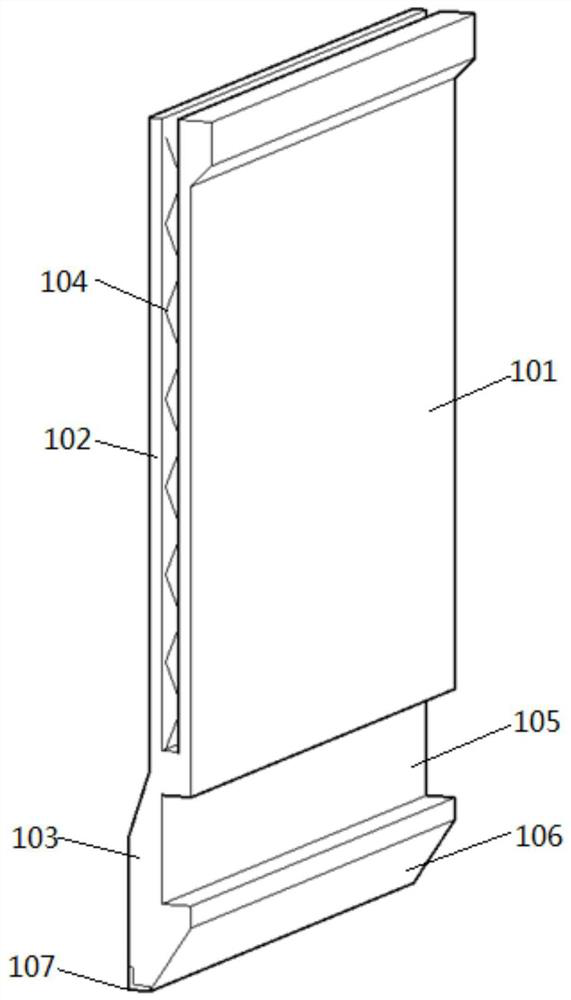

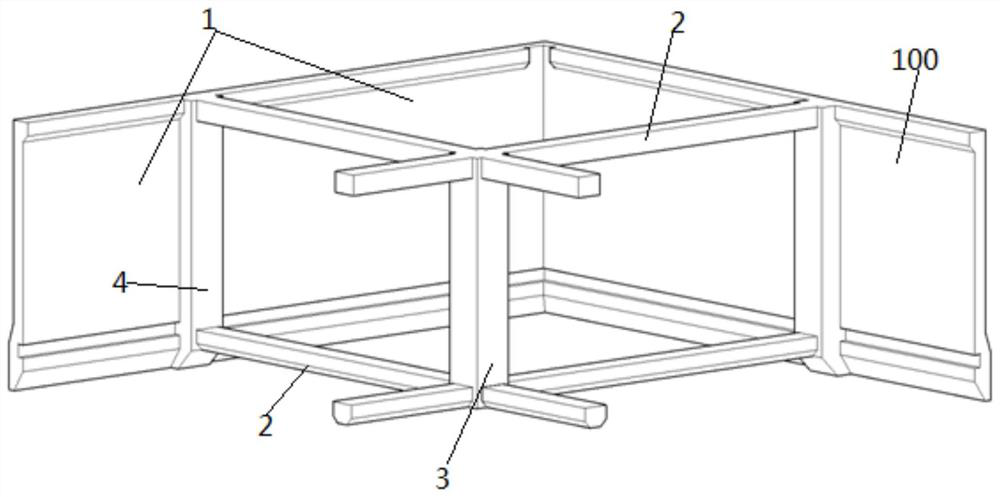

[0034] Embodiments of the present invention provide a caisson type composite shear wall underground garage, such as Figure 1-8 As shown, it includes an exterior wall 1 surrounded by laminated shear walls 100, and the exterior wall 1 is provided with multi-layer frame beams 2 and frame columns 3 between the multi-layer frame beams 2, and two adjacent laminated shear walls Buttress columns 4 are arranged between the force walls 100, and the superimposed shear walls 100, buttress columns 4, multi-layer frame beams 2 and frame columns 3 are connected as an integrated structure, and the integrated structure is sunk to the designated underground through caisson construction. elevation.

[0035] The aforementioned multi-storey frame beam 2 is a laminated beam, and the frame column 3 is a prefabricated column. A reinforced concrete floor 8 is formed on the bottom frame beam by means of cast-in-place concrete, and a concrete laminate floor 5 is provided on the frame beams of other flo...

Embodiment 2

[0044] The embodiment of the present invention provides the construction method of the caisson type laminated shear wall underground garage described in embodiment 1, such as Figure 3-8 As shown, the method includes:

[0045] S1: Hoist the lowest laminated shear wall in place and fix it, hoist the lowest frame beam in place, and hoist frame columns in place and fix them according to the column network.

[0046] S2: Install the buttress column formwork 7 between two adjacent laminated shear walls, and at the same time hoist the frame beams of the upper layer in place, Concrete is poured in the pilaster formwork, at the connection node between the laminated shear wall and the frame beam, and at the connection node between the frame column and the frame beam, and the laminated shear wall, buttress column, frame beam and frame column are poured into an integrated structure .

[0047] The inner leaf plate and outer leaf plate of the laminated shear wall are cast-in-place section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com