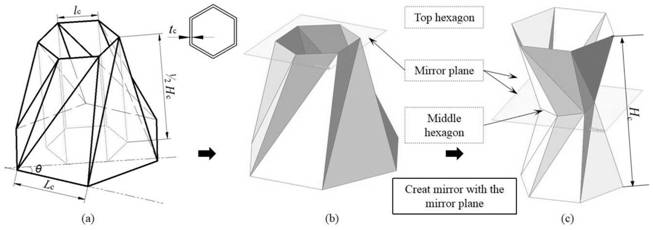

Double-layer spinning origami honeycomb interlayer energy-absorbing material and preparation method thereof

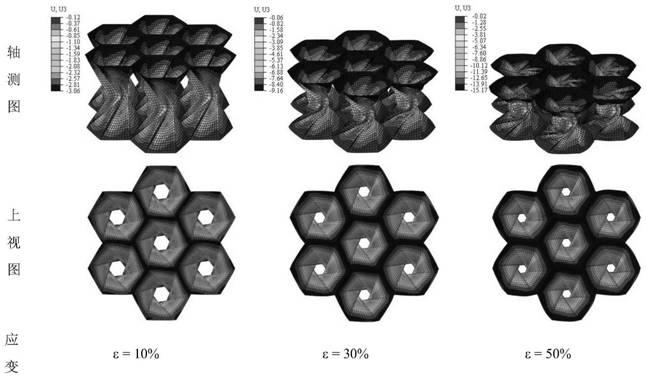

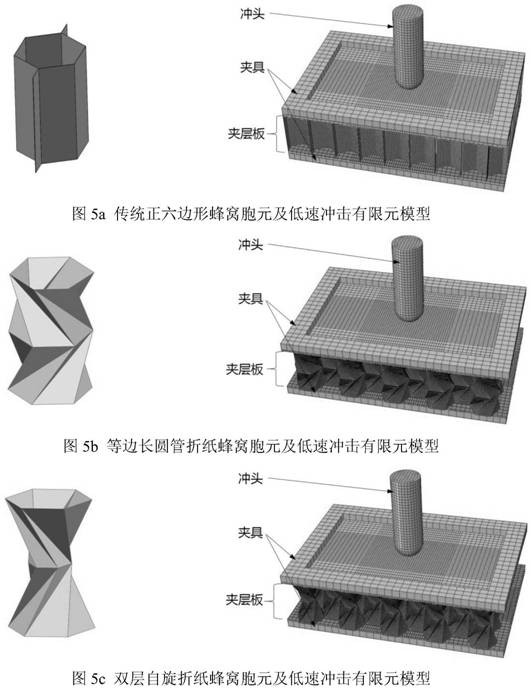

An energy-absorbing material and paper honeycomb technology, applied in the field of energy-absorbing sandwich structure and its preparation, can solve the problems of easy interference, difficult protection effect, high initial buckling load of regular hexagonal honeycomb structure, and achieve light weight, reduce quantity, The effect of reducing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Embodiments of the present invention also provide a method for preparing a double-layer spin origami honeycomb sandwich energy-absorbing material, comprising the following steps:

[0043] Under normal temperature conditions, the preparation steps of the double-layer spin origami honeycomb sandwich energy-absorbing material are as follows:

[0044] 1) Prepare the metal skin according to the design size requirements, and the metal double-layer spin origami honeycomb core can be integrally formed by 3D printing; 2) Clean the surface of the metal skin to be bonded, and put Araldite 2015 two-component room temperature curing paste The paste glue is evenly mixed according to the ratio of 1:1 and spread evenly on the surface to be bonded of the skin, and then the metal skin and the metal core layer coated with the paste glue are placed according to the structural order; 3) Apply about 10~30N The constant pressure allows the product to achieve curing and bonding after 72 hours ...

Embodiment 1

[0050] Prepare the Al 2024-T3 aluminum alloy skin according to the design size length × width × height of 150mm × 100mm × 1mm. Using 3D printing integrated molding technology to obtain Al-3003-H19 aluminum alloy double-layer spin origami honeycomb core, the honeycomb core cell unit is larger than the regular hexagonal side length L c =10mm, the side length of the smaller regular hexagon is 1 / 2 L c =5mm, the cell wall thickness is 0.1mm, the total thickness of the core layer is 30mm, the angle between the normal projection of the small diameter end and the corresponding side of the large diameter end is 0°; the film adopts Araldite 2015 two-component Curing the paste glue at room temperature, mix the paste glue evenly according to the ratio of 1:1 and apply it evenly on the surface to be bonded of the skin, then place the metal skin and the metal core layer coated with the film in accordance with the structural order; apply With a constant pressure of about 20N, the adhesive...

Embodiment 2

[0052] According to the design size length × width × height of 150mm × 100mm × 1mm, the metal skin of 45 steel is prepared, and the aluminum alloy double-layer spin origami honeycomb core of Al-3003-H19 model is obtained by using 3D printing integrated molding technology, the honeycomb core The side length of the larger regular hexagon L c =10mm, the side length of the smaller regular hexagon is 1 / 2 L c =5mm, the cell wall thickness is 0.1mm, the total thickness of the core layer is 30mm, the angle between the normal projection of the small diameter end and the corresponding side of the large diameter end is 30°; the adhesive film is made of LJM-170 resin base Adhesive film: Clean the surface of the metal skin to be bonded, spread the LJM-170 resin-based paper-like adhesive film on the surface to be bonded of the skin, and ensure that there are no obvious air bubbles between the film and the skin, and then place the The metal skin and the metal core layer with the adhesive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com