Preparation method of integrally-formed lipstick tube

A lipstick tube and integrated technology, which is applied in the field of preparation of one-piece molded lipstick tubes, can solve the problems of broken lipstick paste, fall off, and lipstick deterioration, and achieve good antibacterial effect, good buffer effect and good buffer performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

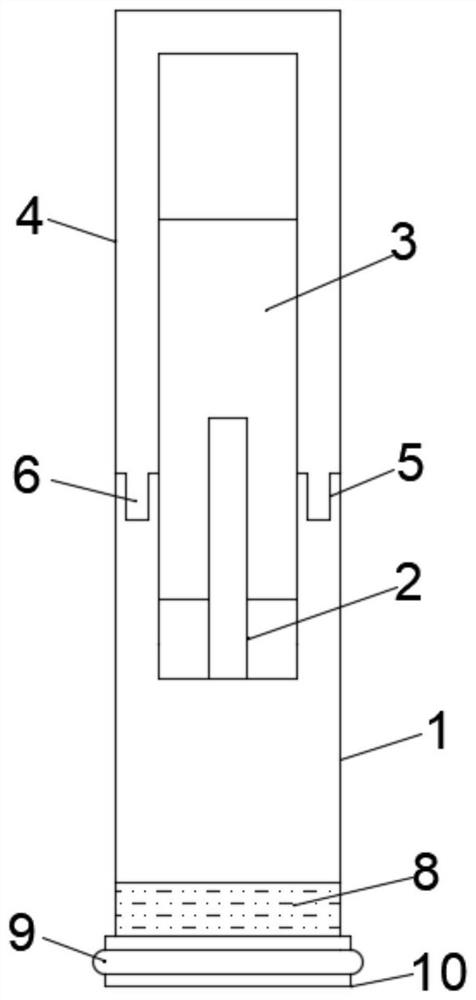

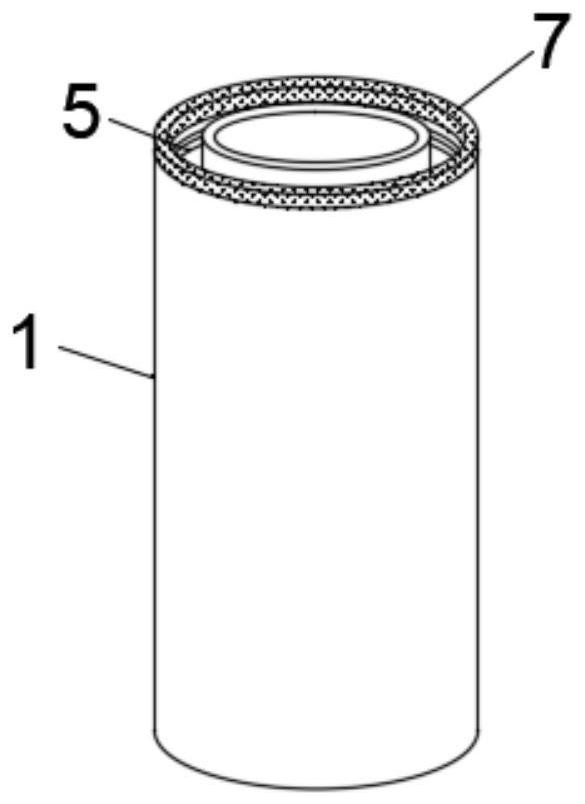

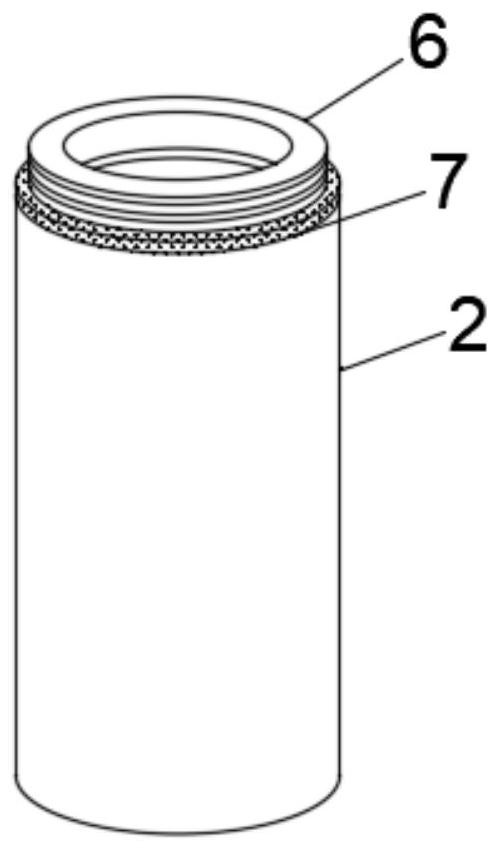

[0028] Example 1: See Figure 1-3 , the present invention provides a technical solution: an integrated molding lipstick tube preparation method, the lipstick tube includes a rotating sleeve 1, a lifting sleeve 3 and a protective sleeve 4, and the rotating sleeve 1 is a hollow cylinder with an open upper end and a closed lower end structure, the center of which is provided with a fixed column 2 for fixing the lipstick paste, and the lifting sleeve 3 is embedded in the inside of the rotating sleeve 1 and is threadedly connected with it; The card slot 5, the protective sleeve 4 is opposite to the opening of the rotating sleeve 1, and a ring 6 of a raised structure is provided on the opening end surface, and the snap ring 6 is adapted to be embedded in the card slot 5 and threadedly connected with it; the rotating sleeve 1 The bottom is provided with a counterweight structure and a buffer structure.

[0029] In this embodiment, a layer of elastic sealing ring 7 is pasted on the o...

Embodiment 2

[0033] Embodiment 2: the preparation method of lipstick tube specifically comprises following preparation steps:

[0034] S1: Use PBT material as raw material, mix it with natural antibacterial agent, add additives and mix evenly, put the mixed material into an injection molding machine for granulation, and obtain PBT masterbatch;

[0035] S2: Load the PBT masterbatch obtained above into an injection molding machine, heat and pressurize it, and inject it into a molding mold to form a lifting sleeve 3, a protective sleeve 4, and a rotating sleeve 1 with a fixed column 2;

[0036] S3: Using stainless steel metal powder as a raw material, a counterweight structure compatible with the bottom of the rotating sleeve 1 is prepared by injection molding, and the counterweight structure is pasted and fixed on the bottom of the rotating sleeve 1 by glue;

[0037] S4: Prepare the cushioning structure with rubber as raw material, and install it at the bottom of the counterweight structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com