Medical trauma hemostasis composite dressing

A trauma and composite polymer technology, applied in the field of medical supplies, can solve the problems of non-antibacterial wound healing, limiting the effective use of dressings, and adhesion between dressings and wounds, achieving hemostasis speed and promoting wound healing, high water absorption, The effect of fast hemostasis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

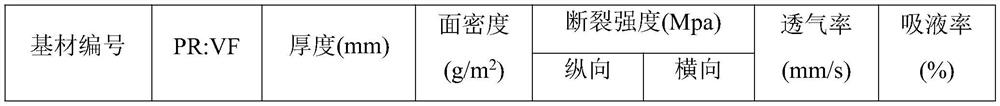

[0031] Preparation of dandelion fluff / viscose fiber nonwoven fabric:

[0032] (1) After collecting 500 g of dandelion fluff and ultrasonically activating it in 0.5 mol / L sodium bicarbonate solution, wash until the washing solution is neutral, and obtain activated dandelion fluff after drying;

[0033] (2) opening treatment of activated dandelion fluff fiber (PR) and viscose fiber (VF);

[0034] (3) form short fibers evenly distributed in warp and weft after the fiber carding machine after opening is carded;

[0035] (4) the short fiber is laid into a fiber net through a web-laying machine;

[0036] (5) Put the fiber web into the spunlace machine and composite 2-4 times with spunlace on both sides; entangle dandelion fibers and viscose fibers together to obtain dandelion fluff / viscose fiber non-woven fabric base material; wherein, The pressure of spunlace is 2-3MPa, and the feeding and discharging speed is 14-16m / min;

[0037] The viscose fiber is prepared from crop stalks b...

Embodiment 2

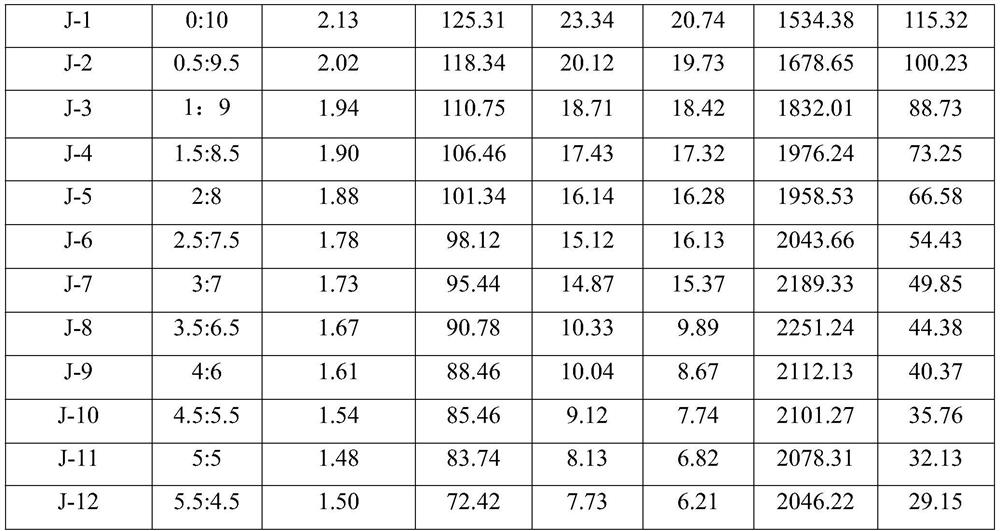

[0044] Investigation of the amount of gluten added:

[0045] In 1000g 1wt% oxidized sodium alginate aqueous solution, add gluten protein part by part (0.1g / part) under stirring condition, along with the increase of gluten protein adding part, sol liquid viscosity increases gradually, when adding gluten protein amount is greater than 10 During the time, the gluten protein cannot completely dissolve and react, and the sol formed is uneven, and there is unreacted gluten protein powder in the sol; the present invention selects the addition ratio of gluten protein and oxidized sodium alginate to be less than 1: 10, preferably 0.5-1 : 10.

[0046] Preparation of composite biopolymer sol:

[0047] Get 0.5g gluten protein and add in 1000g 1wt% oxidized sodium alginate aqueous solution at 30-40 ℃ in 250r / min stirring reaction is complete and then add 125mL4wt% chitosan acetic acid solution (1wt% degree of deacetylation 85% chitosan and 3wt% % carboxymethyl chitosan) to obtain composi...

Embodiment 3

[0061] Preparation of medical trauma hemostatic composite dressing:

[0062] The non-woven fabrics J-1 to J-12 prepared in Example 1 were used as substrates, and the composite biopolymer sol R-2 prepared in Example 2 was coated on the surface, and the composite biopolymer sol R-2 was vacuumized in a vacuum device and then taken out. , hot rolled at 50-60°C under a three-stage roller press, dried and sterilized to obtain a medical hemostatic composite dressing; sequentially recorded as RJ-12, RJ-22, RJ-32, RJ-42, RJ-52, RJ-62, RJ-72, RJ-82, RJ-92, RJ-102, RJ-112, RJ-122;

[0063] The performance of the above-mentioned medical hemostatic composite dressing was tested, and the results are shown in Table 3.

[0064] table 3.

[0065]

[0066] It can be seen from the data in Table 3 that with the increase of the dandelion fluff content in the non-woven fabric substrate, the breaking strength of the dressing showed a decreasing trend, the air permeability first increased and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com