Non-thermal processing treatment process for reducing total sensitization of wheat flour

A non-thermal processing and treatment technology, applied in the field of safety and quality of wheat flour, to achieve the effect of reducing the total allergenicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

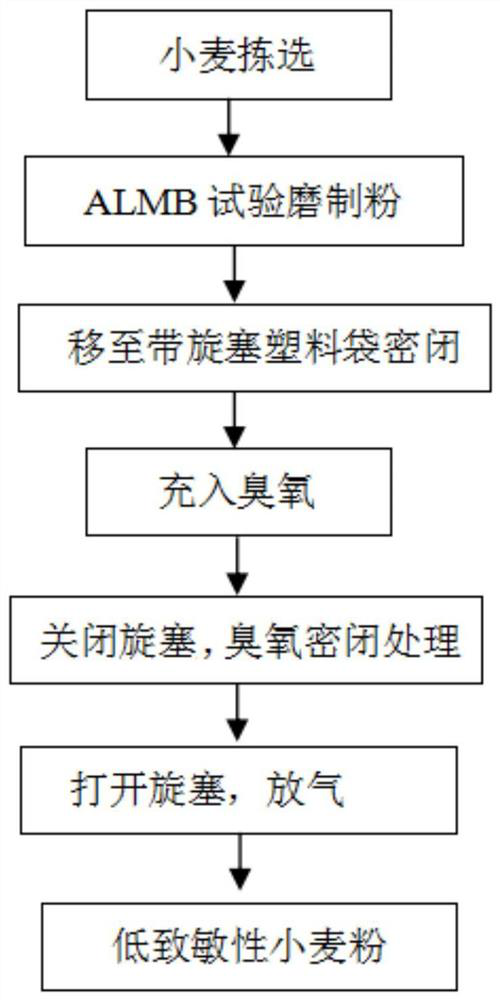

[0034] Step 1. Select the high-quality Gaoyou 2018 wheat produced in Xingtai Baixiang in 2019, and use the Buhler ALMB test mill to mill the wheat. The flour extraction rate is 60%, and the wheat flour passes through an 80-mesh sieve;

[0035] Step 2, transfer the wheat flour to a plastic bag with a closed cock mouth thickness of 24 wires, and place it in an airtight manner;

[0036] Step 3. Open the cock, connect it closely with the outlet of the ozone tube of the ozone generator, and fill it with ozone gas. After the mass ratio of ozone and wheat flour in the plastic bag reaches 2400mg / kg, close the cock and the ozone generator;

[0037] Step 4: Place the plastic bag filled with wheat flour and ozone in a shaker with a rotating speed of 120r / min, seal the ozone for 90 minutes, open the cock to deflate for 1 minute, and then close the cock; the wheat flour with low total allergenicity is obtained.

Embodiment 2

[0039] Step 1. Select the high-quality Gaoyou 2018 wheat produced in Xingtai Baixiang in 2019, and use the Buhler ALMB test mill to mill the wheat. The flour extraction rate is 65%, and the wheat flour passes through a 100-mesh sieve;

[0040] Step 2, transfer the wheat flour to a plastic bag with a closed cock mouth thickness of 24 wires, and place it in an airtight manner;

[0041] Step 3. Open the cock, connect it tightly with the outlet of the ozone tube of the ozone generator, and fill it with ozone gas. After the mass ratio of ozone to wheat flour in the plastic bag reaches 1800mg / kg, close the cock and the ozone generator;

[0042] Step 4: Place the plastic bag filled with wheat flour and ozone in a shaker with a rotating speed of 130r / min, seal the ozone for 60 minutes, open the cock to deflate for 1 minute, and then close the cock to obtain wheat flour with low total allergenicity.

Embodiment example 3

[0044] Step 1. Select the high-quality Gaoyou 2018 wheat produced in Xingtai Baixiang in 2019, and use the Buhler ALMB test mill to mill the wheat. The flour extraction rate is 70%, and the wheat flour passes through a 120-mesh sieve;

[0045] Step 2, transfer the wheat flour to a plastic bag with a closed cock mouth thickness of 24 wires, and place it in an airtight manner;

[0046] Step 3. Open the cock, connect it tightly with the outlet of the ozone tube of the ozone generator, fill it with ozone gas, and close the cock and the ozone generator after the mass ratio of ozone to wheat flour in the plastic bag reaches 1200 mg / kg;

[0047] Step 4: Place the plastic bag filled with wheat flour and ozone in a shaker with a rotating speed of 140r / min, seal the ozone for 90 minutes, open the cock to deflate for 1 minute, and then close the cock; the wheat flour with low total allergenicity is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com