Intelligent livestock breeding waste treatment equipment

A technology for breeding waste and treatment equipment, which is applied in the fields of animal husbandry wastewater treatment, biological sludge treatment, animal husbandry, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

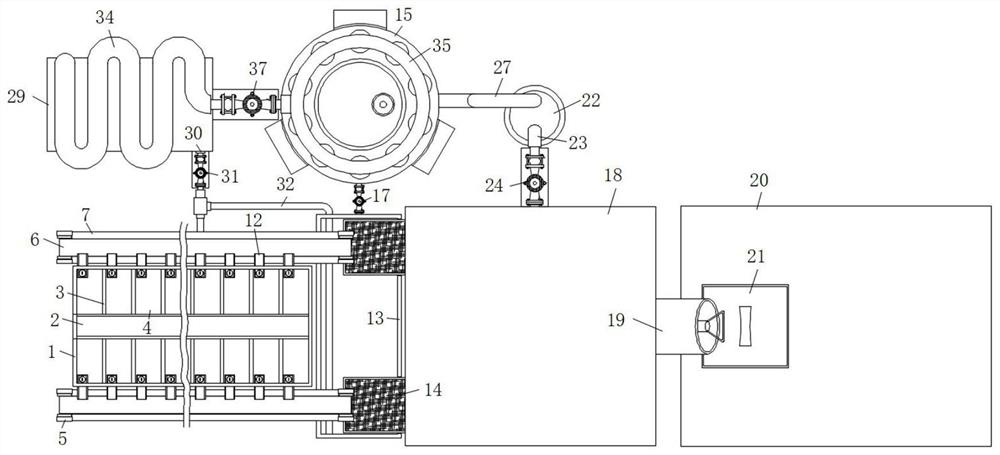

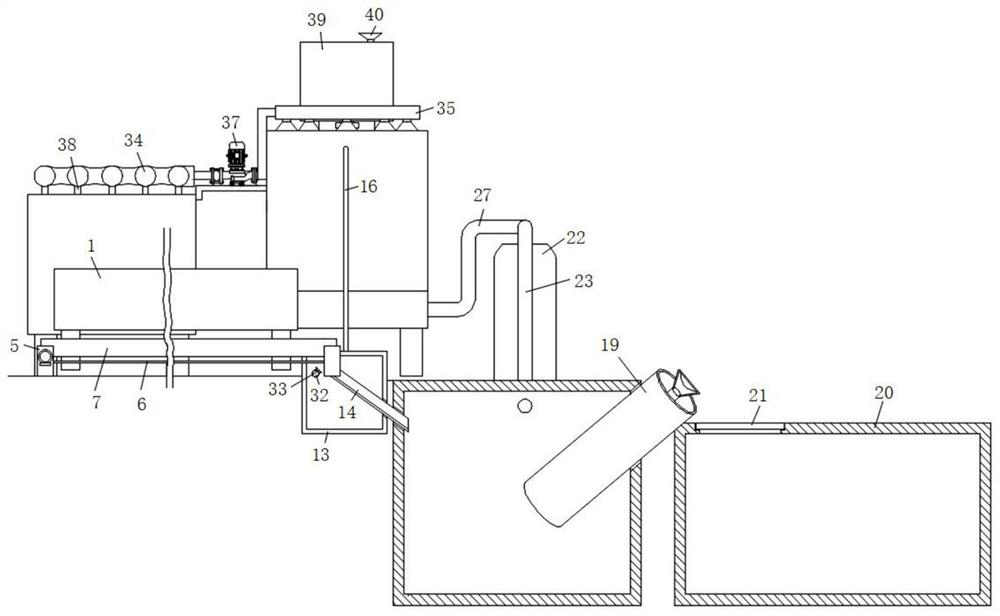

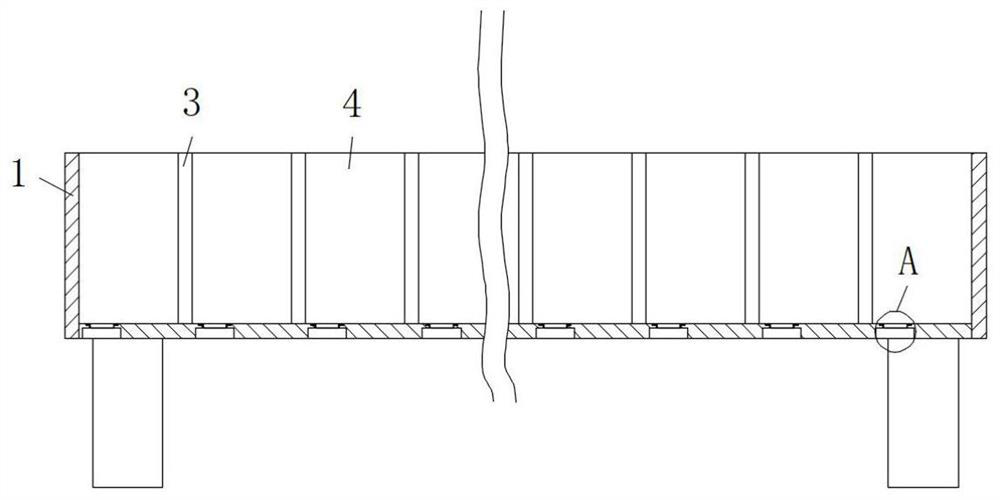

[0034] refer to Figure 1-7, a kind of intelligent processing equipment for animal husbandry waste, including a breeding room body 1, a channel 2 is provided in the middle of the breeding room body 1, and a plurality of partition walls 3 are provided on the front and rear sides of the channel 2, and the partition walls 3 separate the breeding room body 1 Separated into a plurality of breeding rooms 4, the front and rear ends of the breeding room body 1 are provided with support seats 5, and conveyor belts 6 are installed between the support seats 5 at the same end, and a sealing dish 7 is fixedly connected to the top of the support seat 5 at the same end, and The upper belt surface of the conveyor belt 6 is all placed in the sealing dish 7, and one side of the outer bottom surface of the breeding room 4 is provided with a discharge port 8, and one end of the bottom surface of the breeding room 4 near the discharge port 8 on one side is also provided with a circular groove. 9. ...

Embodiment 2

[0037] Such as figure 1 , 2 As shown in and 7, this embodiment is basically the same as Embodiment 1. Preferably, the discharge assembly 19 includes a discharge barrel 191, and the discharge barrel 191 is connected through the side wall of the fermenter 18, and the discharge barrel 191 is close to the fermenter. The bottom side of one end of the 18 side is provided with a material guide hole 192, and the inner wall of the discharge barrel 191 is also in sliding contact with a sealing plug 193, and a pull rod 194 is fixed at the center of one side of the sealing plug 193, and the end of the pull rod 194 is away from the sealing plug 193 and is fixed by a screw. Connect with pulling handle 195.

[0038] In this embodiment, after the solid waste from animal husbandry is fermented, the reactant will pass through the guide hole 192 and enter the discharge barrel 191, and people pull the pull rod 194 to move the sealing plug 193 to discharge the waste for subsequent people. Fertil...

Embodiment 3

[0040] Such as figure 1 and 2 As shown, the present embodiment is basically the same as Embodiment 1. Preferably, four support seats 5 are provided, and the support seats 5 on both sides are respectively fixed on the working surface and the side walls of the draining dish 13, and the water pump one 17 and Water pump two 31 are respectively fixed on the rear side wall of the drain dish 13 and the front end face of the water tank 29 by screws.

[0041] In this embodiment, the first water pump 17 and the second water pump 31 are fixedly connected to the rear side wall of the draining dish 13 and the front end surface of the water tank 29 by screws respectively, so that the operation of the device is more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com