Test device and method for initial permeability of ferrite imaginary part at extremely weak magnetic field and extremely low frequency

A test device, ferrite technology, applied in the direction of permeability measurement, magnetic performance measurement, etc., can solve the imaginary part permeability is not rigorous and accurate, the impact of noise evaluation of quantum precision measurement devices, the imaginary part of the initial permeability There is no such problem, and the measurement process is simple and fast, the ultra-high sensitivity is improved, and the measurement error is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

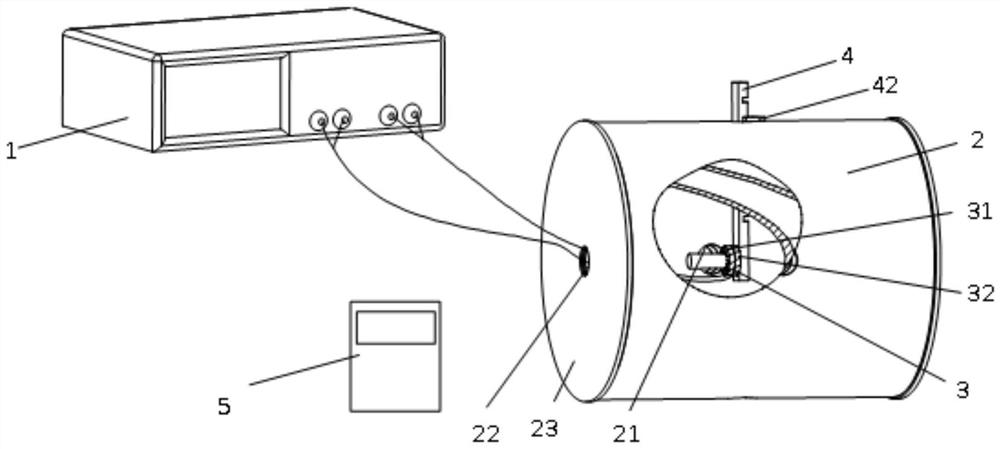

[0062] A method for testing the permeability of the imaginary part of ferrite when the extremely weak magnetic field is extremely low frequency, the flow chart of which is as follows Figure 4 As shown, use the above-mentioned ferrite imaginary part permeability test device at extremely weak magnetic field and extremely low frequency to measure, including the following steps:

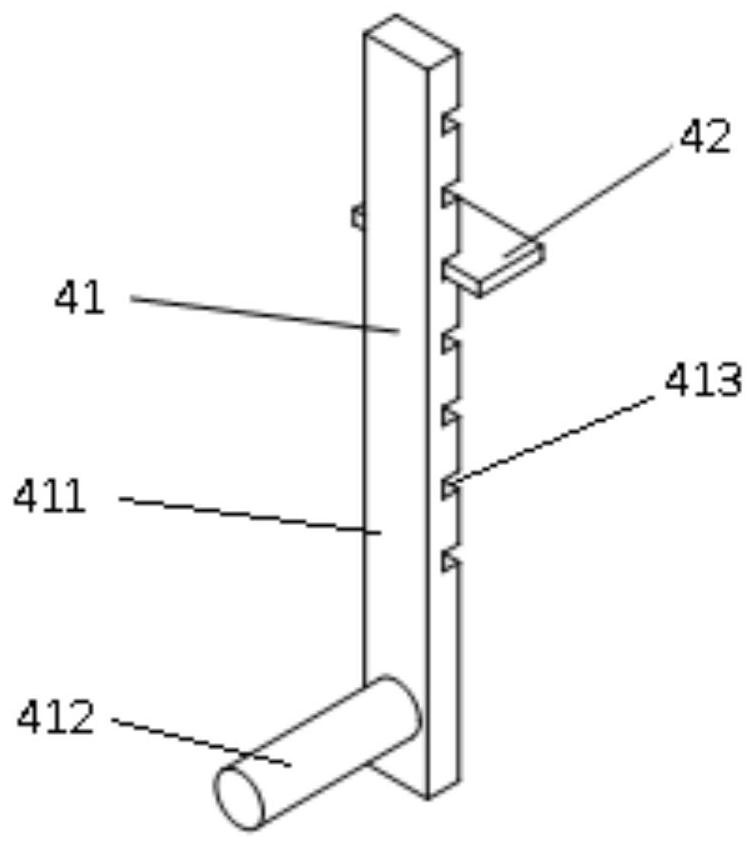

[0063] The construction of the ferrite imaginary part permeability test device at the time of extremely weak magnetic field and extremely low frequency described in S1;

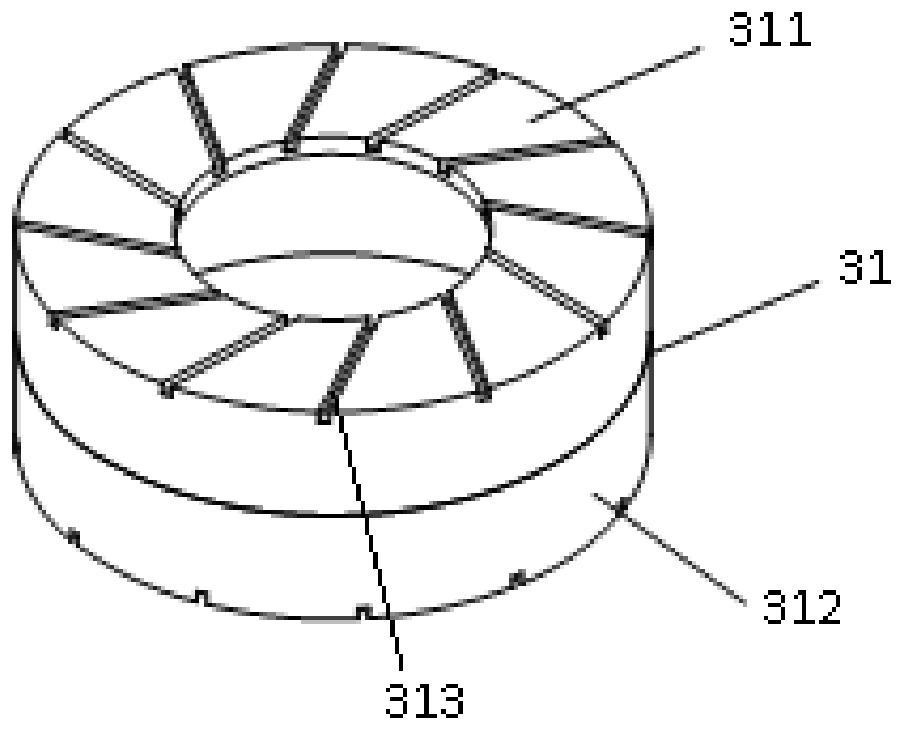

[0064] S1.1 place the ferrite ring to be tested in the shimming coil casing 31, and uniformly wind N turns of the measuring coil 32 outside the shimming coil casing 31 to make the ferrite box 3 to be tested; or Directly take the ferrite test box 3 with the ferrite ring to be tested built-in, and the outside of the ferrite test box 3 is evenly wound with a measuring coil 32;

[0065] S1.2 degaussing the ferrite test box 3 in S1.1;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com