Circulating improved water turbine cavitation erosion initial state discrimination system and method

A state discrimination, water turbine technology, applied in engine testing, machine/structural component testing, measuring devices, etc., can solve problems such as wear on solid walls, high maintenance costs, and aggravated damage to overcurrent components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

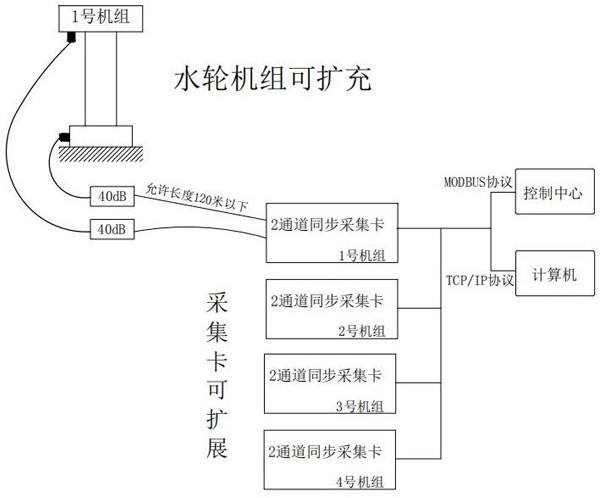

[0055] see Figure 1 to Figure 6 , in this embodiment, the cycle-improved water turbine cavitation initial state discrimination system is connected to field equipment, such as figure 1 As shown, it mainly includes the following equipment and systems:

[0056] (1) On-site measurement layer: It is composed of acoustic emission sensors, top cover vibration velocity sensors, upstream and downstream water level sensors, water pressure pulsation sensors, and large-axis air supply anemometers. Among them: the acoustic emission sensor used is installed on the volute of the hydroelectric unit, which is prone to cavitation and has a good measurement effect, and the upper and lower pipe walls of the draft pipe inspection door to collect; the vibration signal of the top cover of the unit, the pressure pulsation of the inlet and outlet of the fluid machinery Signal Pr, upstream water level H 1 and downstream water level H 2 (to obtain water head data) and other measurement signals are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com