Bagged food cooling system

A cooling system and food technology, applied in the field of food processing and food cooling, can solve the problems of affecting packing, bag hanging or crushing, low cooling efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

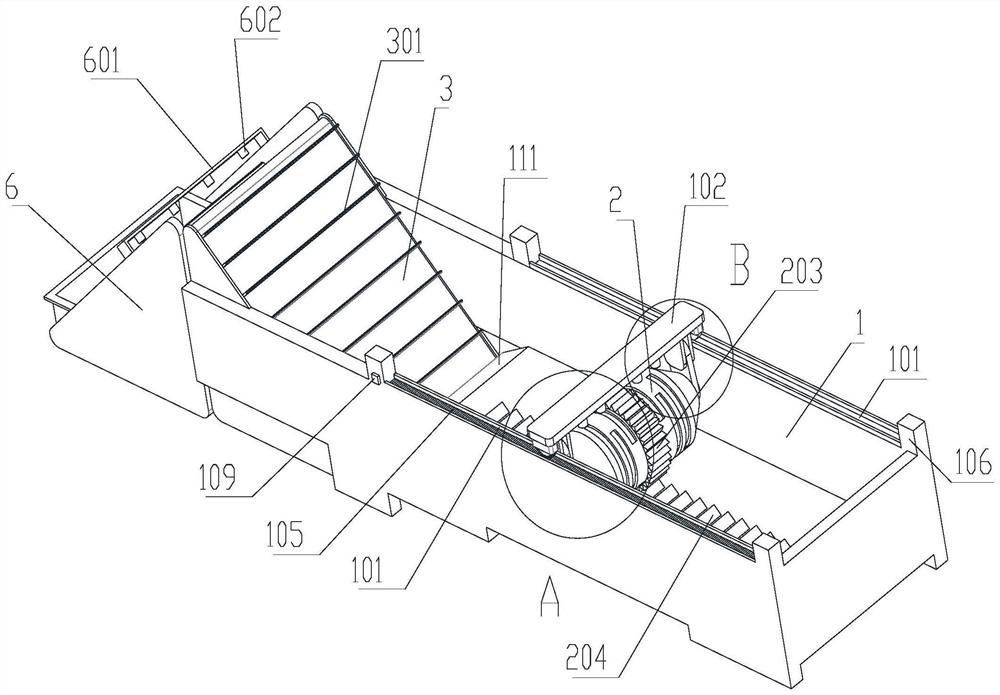

[0036] see Figure 1 to Figure 6 , the present invention provides a bagged food cooling system, comprising a cooling pool 1, a moving roller mechanism 2 is arranged in the cooling pool 1, an inclined conveyor belt 3 is arranged at one end of the cooling pool 1, and an inclined guide belt is connected to one end of the conveyor belt 3 plate 4, the bottom of the guide plate 4 is provided with a condensed water removal mechanism 5;

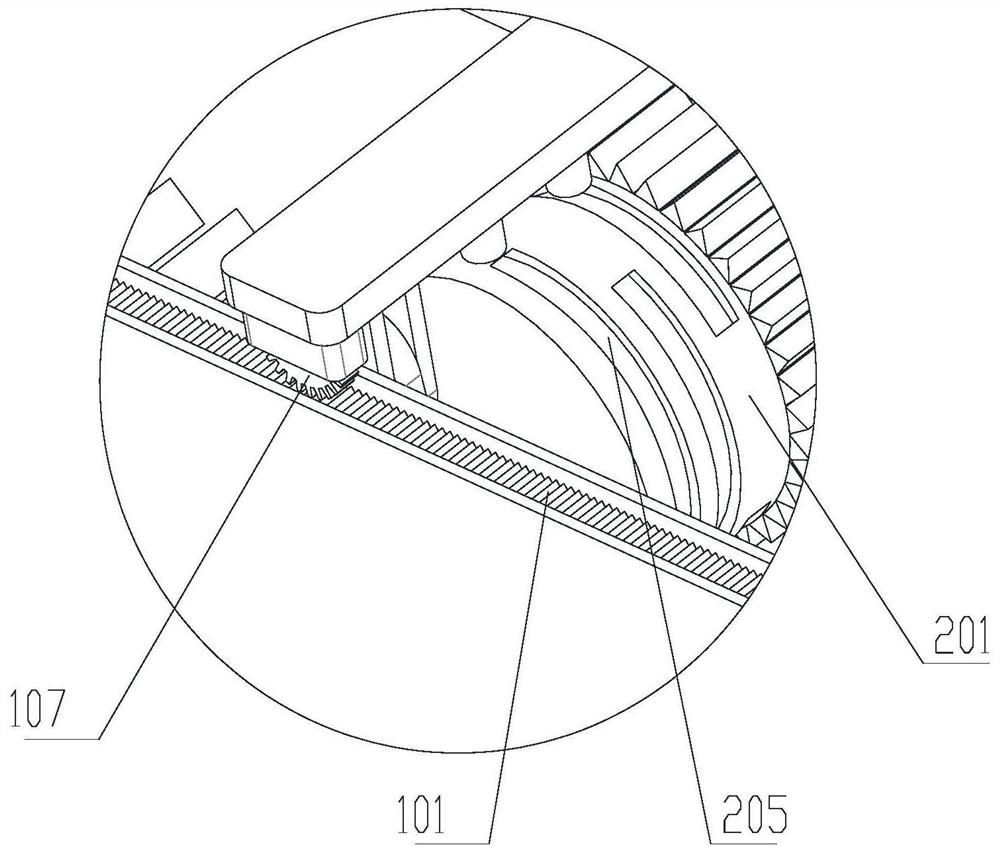

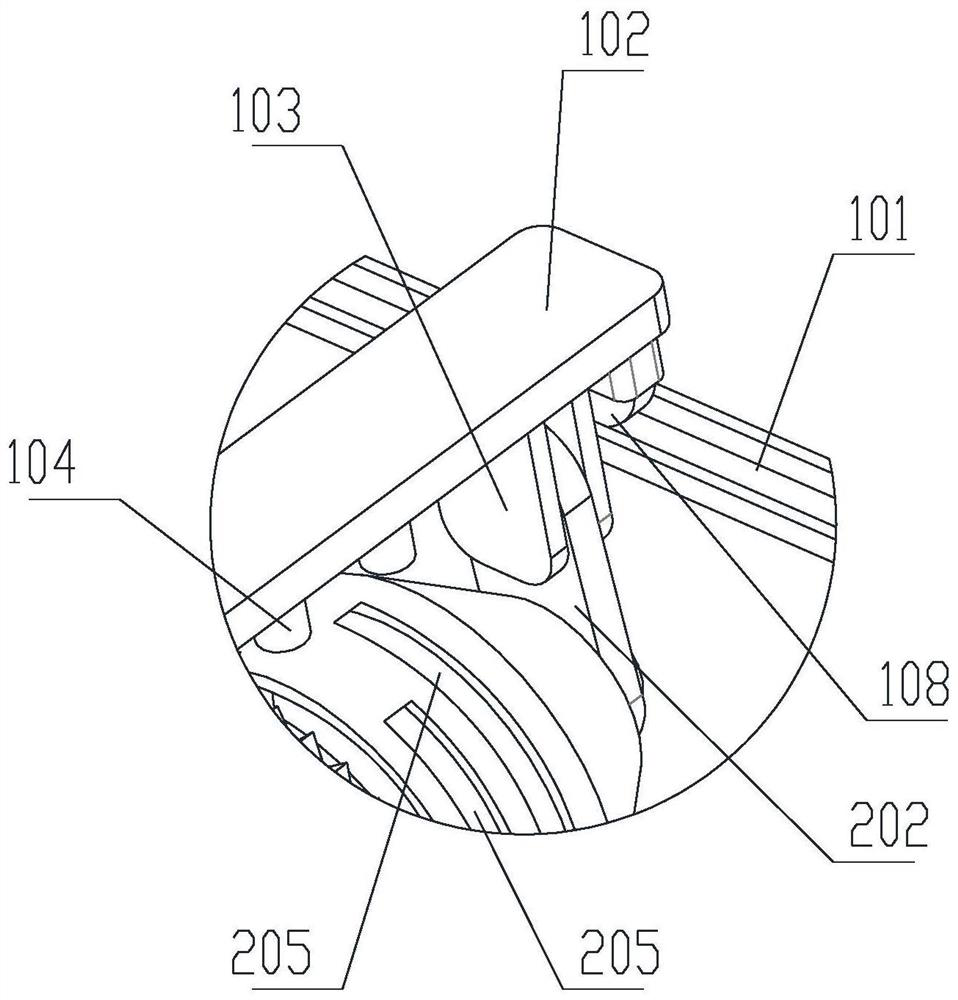

[0037]The top of the cooling pool 1 is provided with a track 101, a movable roller support frame 102 is placed on the track 101, and a moving wheel is arranged at the bottom of the roller support frame 102. The roller mechanism 2 includes a roller 201 axially perpendicular to the side wall of the cooling pool 1, The two ends of the drum 201 are fixedly provided with a rotating shaft, the rotating shaft is connected with a connecting rod 202, the bottom of the drum support frame 102 is fixedly provided with a connecting seat 103, and the upper and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com