Unattended transformation system and method for oil field three-phase dehydration closed oil transportation station yard

An oil station, three-phase technology, which is applied in the field of unattended transformation system of three-phase dehydration and closed oil transportation stations in oil fields, can solve the problems of easy blockage of sewage pipelines, inability to protect station safety and equipment, and inability to automatically monitor pressure, etc. , to achieve the effect of improving the safety of production operations, reducing the number of manual inspections, and reducing the labor intensity of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0041] It should be noted that the structures, proportions, sizes, etc. shown in this specification are only used to cooperate with the content disclosed in the specification for the understanding and reading of those familiar with this technology, and are not used to limit the conditions for the implementation of the present invention , any modification of structure, change of proportional relationship or adjustment of size shall still fall within the scope covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. .

[0042] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invention without...

Embodiment 1

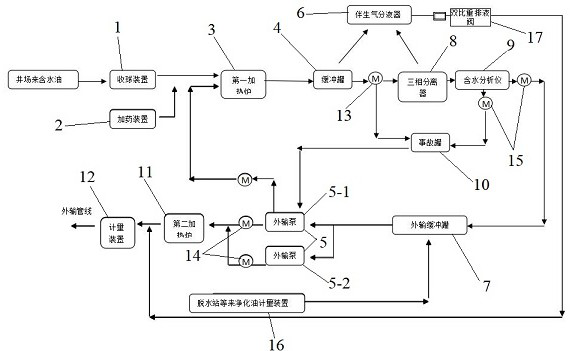

[0044] Such as figure 1 As shown, the present invention discloses an unattended reconstruction system for three-phase dehydration airtight oil delivery stations in oilfields, including a ball collecting device 1, a dosing device 2, a first heating furnace 3, a buffer tank 4, an external delivery pump 5, Associated gas separator 6, external transport buffer tank 7, three-phase separator 8, emergency tank 10, second heating furnace 11, metering device 12, external transport pipeline and control components, the output end of the ball collecting device 1 passes through the pipeline Connected to the first heating furnace 3, the pipeline between the ball collecting device 1 and the first heating furnace 3 is also connected to the dosing device 2, and the output end of the first heating furnace 3 is connected to the buffer tank 4 through the pipeline, and the buffer tank 4 The output ends are respectively connected to the associated gas separator 6 and the three-phase separator 8 thr...

Embodiment 2

[0046] Preferably, a first pressure transmitter and a first temperature transmitter are arranged inside the ball collecting device 1, wherein the first pressure transmitter and the first temperature transmitter are respectively electrically connected to the control assembly.

[0047] The ball collecting device 1 is used to release the pipe pig. The pipe pig is used to regularly clean the dirt in the pipeline and detect internal corrosion. only when it works.

[0048] The ball collecting device 1 is equipped with a first pressure transmitter and a first temperature transmitter to realize overpressure alarm and temperature control functions. When the operating temperature of the ball collecting device 1 reaches 40°C or the pressure exceeds 0.5 MPa, it will stop running. Station safety and equipment play a protective role.

[0049] Preferably, the first heating furnace 3 is provided with an automatic ignition burner, wherein the model of the automatic ignition burner is BTG 28P,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com