Method for increasing communication length of SAGD horizontal section of double horizontal wells

A dual-horizontal well, horizontal section technology, applied in chemical instruments and methods, earthmoving, wellbore/well components, etc. The problem of high storage viscosity, etc., achieves the effect of good technology implementation, easier production control, and improved seepage capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

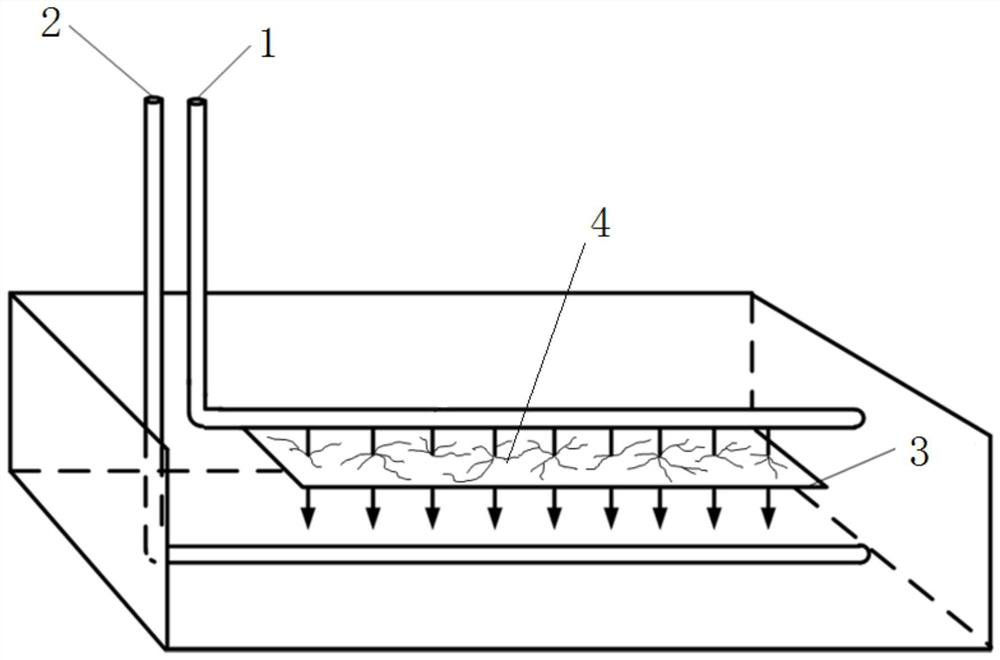

[0053] This embodiment provides a process of increasing the producing length of the horizontal section by using small-diameter deep-penetrating dense perforation stimulation and mixed viscosity-reducing agent mixed injection before cyclic preheating of a certain oilfield block.

[0054] In an oil reservoir block in Xinjiang Oilfield, the burial depth of the reservoir is 200m, the average formation pressure is 2.1MPa, the formation temperature is 18.0°C, the effective thickness of oil layer 5 is 15m, the porosity is 28.8%, the permeability of the oil layer is 800mD, and the average crude oil viscosity at 50°C is 50000mPa. s, oil saturation 65.0%.

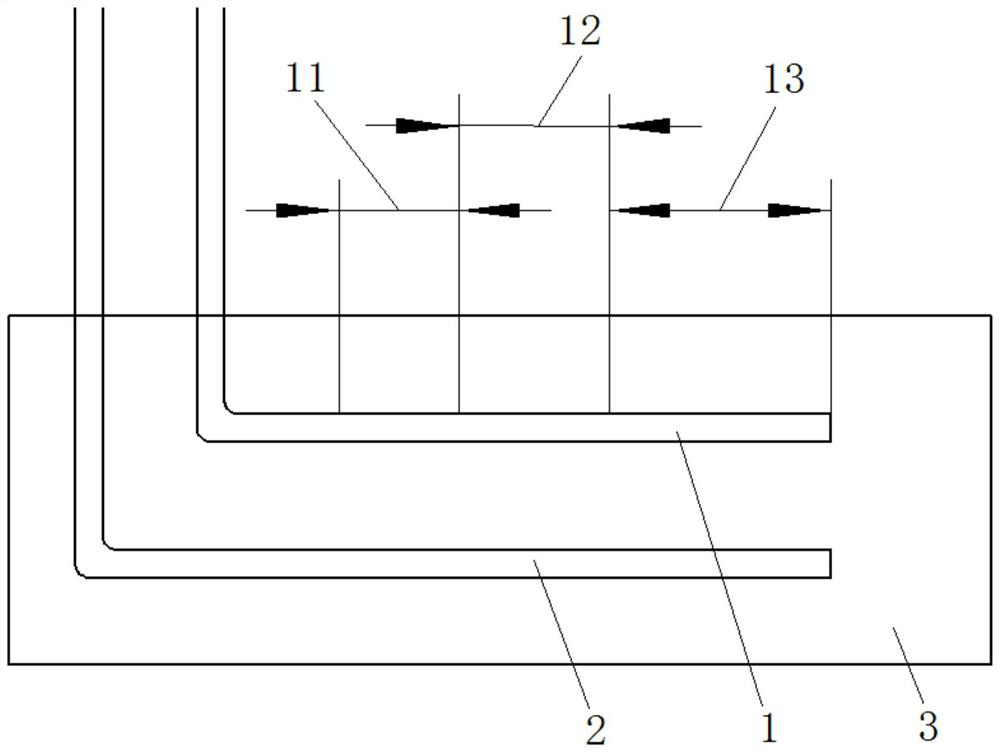

[0055] The reservoir block is planned to be exploited by SAGD technology. In order to make full use of the thickness of the oil layer, the horizontal section of a steam injection well 1 is arranged at the bottom of the oil layer 5, and the horizontal section of an oil production well 2 is arranged 5m above the bottom of the oil reserv...

Embodiment 2

[0072] This example provides a case of SAGD in an oilfield block that has been transferred to the production stage and the low-level production degree transformation case, using large-aperture deep-penetrating low-density perforation stimulation, electric pulse artificial fractures and mixed viscosity reducer mixed injection to improve the horizontal section The process of using length.

[0073] In the SAGD block of a certain oil reservoir in Xinjiang Oilfield, the burial depth of the oil reservoir is 250m, the average formation pressure is 2.5MPa, the formation temperature is 18.0°C; the effective thickness of the oil layer is 15m, the porosity is 32%, the permeability of the oil layer is 2500md, and the average crude oil viscosity at 50°C is 25000mPa. s, the oil saturation is 77.0%.

[0074] The reservoir block has entered the production stage of SAGD production, the length of the horizontal section of steam injection well 1 and the horizontal section of oil production well ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com