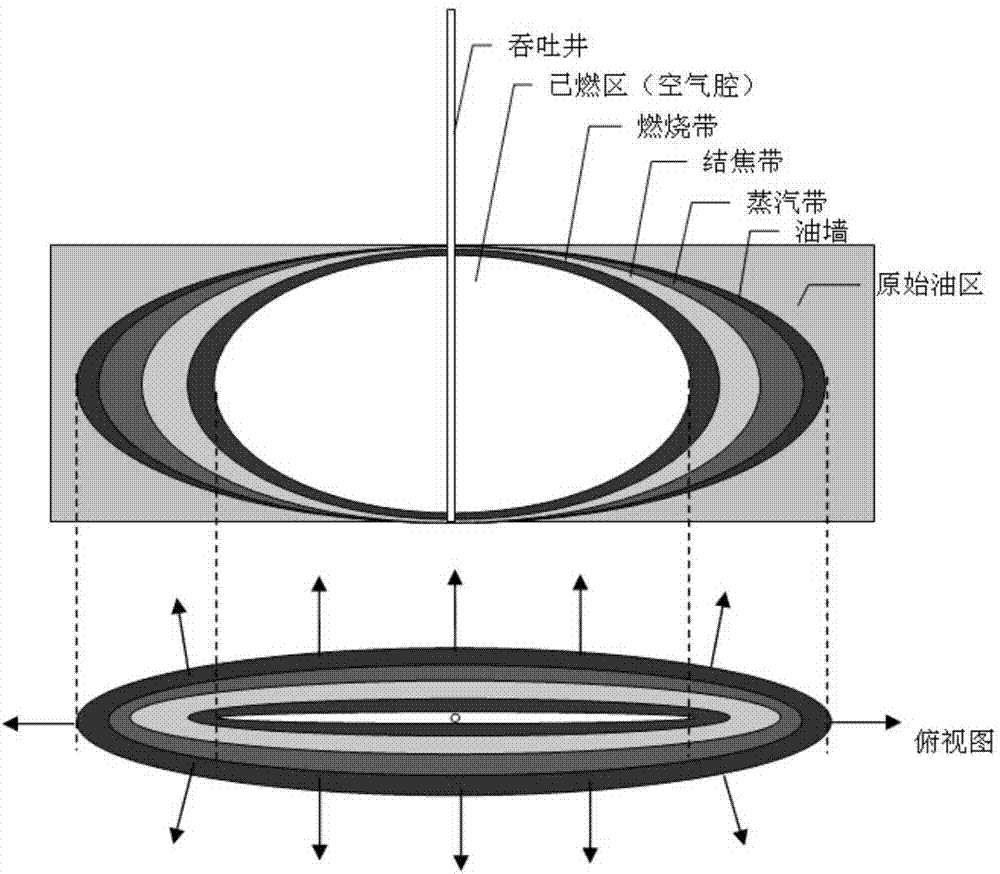

Fracture-assisted combustion of oil in-situ stimulation thickened oil exploiting method

A technology of burning oil layers and heavy oil, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of difficult air injection and heavy oil reservoir development, and achieves increased heating range and cycle cumulative production The effect of increasing and increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Reservoir 1 The depth of the reservoir is 800m; the thickness of the oil layer is 19.6m; the permeability of the oil layer is 610×10 -3 μm 2 ; Reservoir temperature 32°C; Crude oil viscosity 5100mPa.s; Crude oil density 0.9240g / cm 3 ; Oil saturation 58.9%; J 1 、J 2 The wells are two production wells in the reservoir, and the conventional cold recovery production is lower than the economic limit production. Formation fracture pressure is 18MPa.

[0035] (1) to J 1 Perforate the casing in the oil section of the well, and use hydraulic fracturing technology to press out 40m long artificial fractures, and fill the fractures with fracturing proppant. The main construction parameters include: accumulatively adding 40m of ceramsite with a particle size of 0.425mm to 0.850mm 3 ; Prefluid 40m 3 ; Carrying fluid 105m 3 ; Displacement 3.5m 3 / min; the sand ratio increases step by step, from 10% to 80%, and after reaching the highest sand ratio, add 5m of displacement flui...

Embodiment 2

[0041] Reservoir 2 The depth of the reservoir is 1200m; the thickness of the oil layer is divided into 3 small thin layers, with a total thickness of 11.2m; the permeability of the oil layer is 410×10 -3 μm 2 ; Reservoir temperature 30°C; Crude oil viscosity 4800mPa.s; Crude oil density 0.9220g / cm 3 ; Oil saturation 55.9%. J 11 and J 12 The wells are two production wells in the reservoir, and conventional cold production has no production capacity.

[0042] (1) to J 12 The casing of the oil zone of the well is perforated.

[0043] (2)J 12 The well adopts hydraulic fracturing technology to press out 35m long artificial fractures, and adds 30m of proppant 3 , 3 thin oil layers to achieve up and down penetration. The specific construction parameters include accumulatively adding 30m of ceramsite with a particle size of 0.425mm to 0.850mm 3 ; Prefluid 35m 3 ; Carrying fluid 85m 3 ; Displacement 3.2m 3 / min; the sand ratio increases step by step, from 10% to 80%, and af...

Embodiment 3

[0051] Reservoir 3 The depth of the reservoir is 2600m; the thickness of the oil layer is divided into 2 small layers, with a total thickness of 14.2m; the permeability of the oil layer is 550×10 -3 μm 2 ; Reservoir temperature 75°C; Degassed crude oil viscosity at formation temperature 22800mPa.s; Crude oil density 0.9820g / cm 3 ; Oil saturation 67.9%. L 1 and L 2 The wells are two production wells in the reservoir, and conventional cold production has no production capacity. In the early stage, supercritical pressure steam injection test production was carried out, and the average daily production was lower than 3t, which had no economic benefits. The formation fracture pressure is 46MPa, and the maximum gas injection pressure of the surface compressor is 35MPa.

[0052] (1) to L 1 The perforation section of the well casing adopts hydraulic fracturing technology to press out 40m long artificial fractures, and adds 35m of proppant 3 , The two oil layers are connected up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com