Aluminum profile smelting furnace

A technology for smelting furnaces and aluminum profiles, applied in the field of aluminum profile processing equipment, can solve the problems of low heating efficiency of aluminum profiles, slow heating process of aluminum profiles, slow disassembly and installation, etc., achieve fast heating speed, reduce processing costs, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

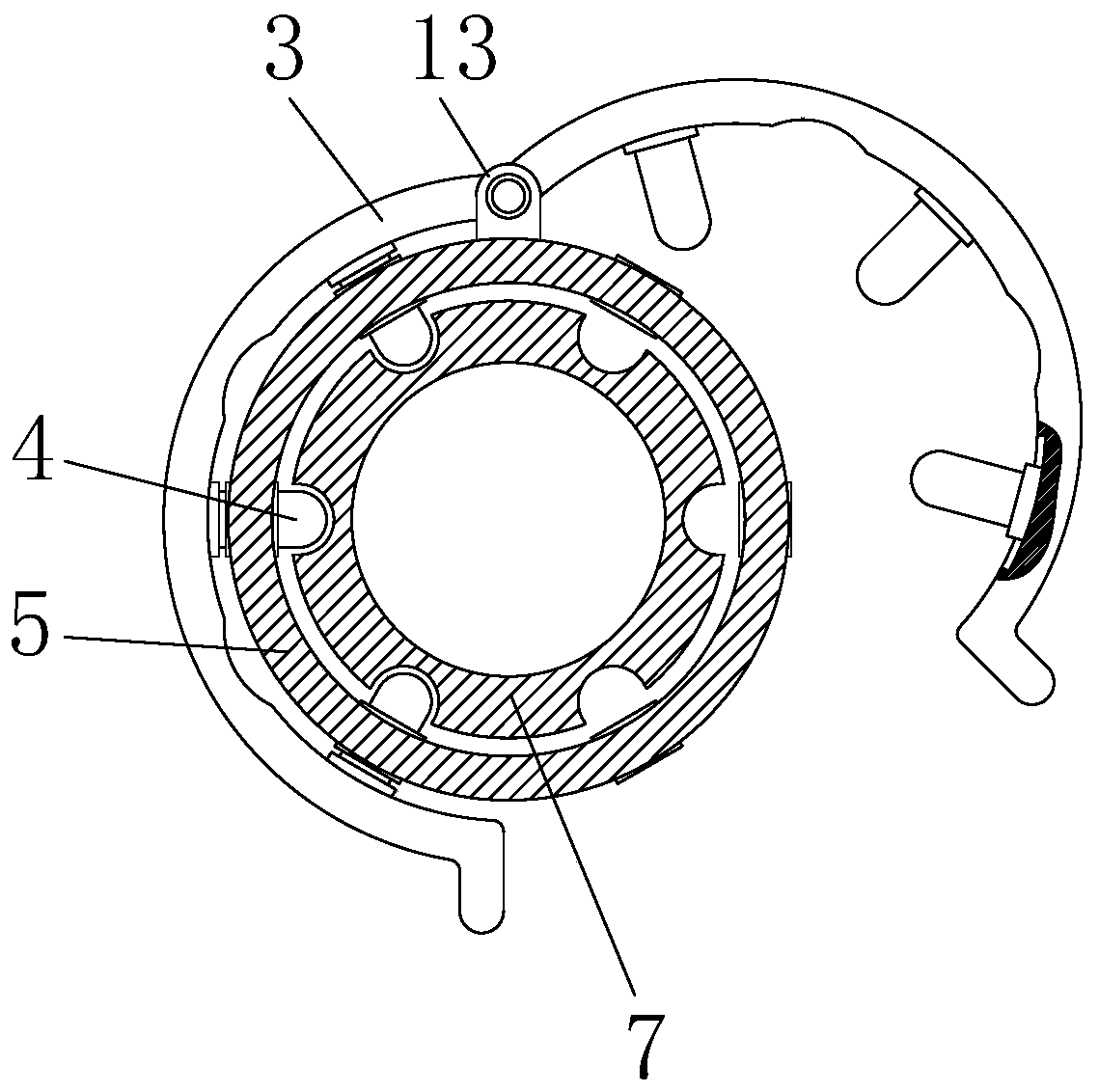

[0025] use Figure 1-Figure 5 An aluminum profile smelting furnace according to an embodiment of the present invention is described as follows.

[0026] Such as Figure 1 to Figure 3 As shown, the aluminum profile smelting furnace described in the present invention includes a box body 1 and a furnace body 7; the inner cavity of the box body 1 is provided with a furnace body 7; The heating resistance wire 2 is connected directly to the winding; the bottom of the heating resistance wire 2 is welded with a fixed plate 9; The block 14 is movably connected; the top of the furnace body 7 is sleeved with a cap 5; the outside of the cap 5 is sleeved with a connecting clamp 3; the connecting clamp 3 and the cap 5 are connected by a connecting seat 13 in rotation, The connecting hoop 3 is an elastic metal piece, and the side of the connecting hoop 3 close to the furnace body is provided with an arc groove; the inner surface wall of the connecting hoop 3 is slidably connected with a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com