Method for improving recovery ratio of super heavy oil reservoir

A recovery factor and ultra-heavy oil technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve problems such as failure to break through production capacity, high viscosity of formation crude oil, and high seepage resistance of steam injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

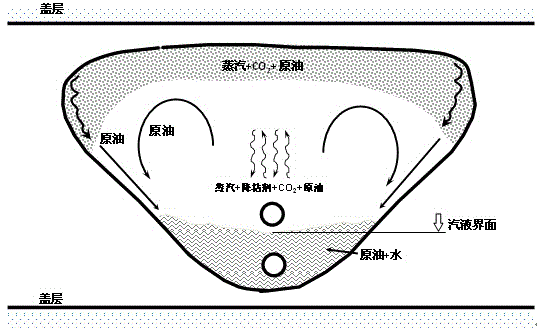

[0029] Such as figure 1 as shown, figure 1 It is a flow chart of a specific embodiment of the method for enhancing the recovery of ultra-heavy oil reservoirs of the present invention.

[0030] In step 101, two parallel horizontal wells are preheated. In the oil layer of the heavy oil reservoir, two parallel horizontal wells are deployed, located close to the bottom of the oil layer, and the two wells are kept at a certain distance. Using steam injection cycle preheating technology. Both horizontal wells adopt dual tubing structure. Among them, the long tubing is used to inject steam, and the steam injection rate is maintained at 50-80t / d; at the same time, the short tubing is used to discharge fluid at a constant bottomhole flow pressure, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com