Expansion increment deflagration fracturing method

A deflagration and fracturing technology, which is used in earth-moving drilling, production of fluids, wellbore/well components, etc., can solve the problem of limited deflagration and fracturing functions and effects, poor pore connectivity of perforation channels, and limited deflagration and fracturing dosage. and other problems to achieve the effect of improving connectivity, reducing damage and damage, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

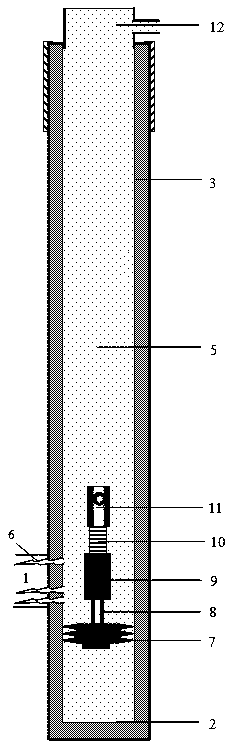

[0046] see figure 1 , a deflagration fracturing method for expansion and increment, comprising the following steps:

[0047] Perforation: perforating in the wellbore 3 where the well section of the target reservoir is located;

[0048] Capacity expansion: improve the connectivity between the perforation channel 6 and the primary pores in the near-wellbore area of the reservoir, and expand the pore volume in the near-wellbore area of the reservoir; the methods for realizing capacity expansion include perforation expansion and plugging expansion; The pore density, pore diameter and pore depth; plugging removal and expansion refers to the recovery and improvement of the connectivity between the perforation tunnel 6 and the primary pores through repeated injection and flowback of the plugging removal fluid into the perforation tunnel 6, increasing the reservoir near the wellbore. The pore volume of the zone; the plugging solution is water-based plugging solution and / or oil-ba...

Embodiment 2

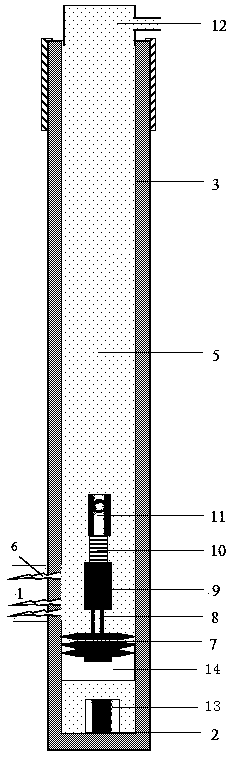

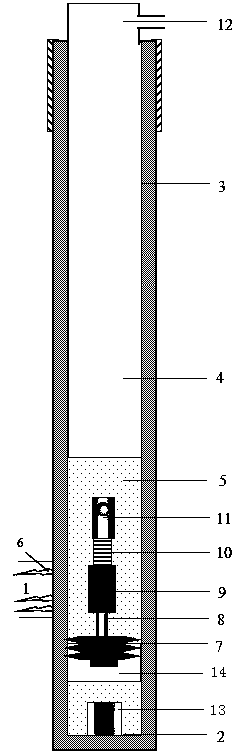

[0056] see figure 2 , on the basis of the above-mentioned basic scheme, after setting the blockage 7, set the gas plug 14 in the wellbore 3 below the blockage 7, the gas plug 14 refers to the gas slug arranged in the wellbore 3 below the blockage 7, the blockage 7 and its lower Adjacent gas plugs 14 jointly form the bottom block; gas plug 14 is a kind of nitrogen, air or carbon dioxide gas; gas plug 14 also can be the mixed gas of nitrogen and air or the mixed gas of carbon dioxide gas and air.

[0057] The setting method of air plug 14 comprises exhaust method or integrated method, wherein:

[0058] The pumping method is: before setting the bottom stop, the liquid in the wellbore 3 is pumped to the surface, so that the liquid in the wellbore 3 drops below the bottom boundary of the perforated well section 1 and above the artificial well bottom, and then the liquid in the wellbore A bottom stop is set above the liquid level in 3, and the sealed air below the bottom stop cons...

Embodiment 3

[0063] 1. Brief introduction of oil production well

[0064] Well number: j06-19, horizon: Y, perforated section: 1615.0-1618.0m, perforation thickness: 3.0m, artificial well bottom: 1769.6m, reservoir casing: φ 内 124.26mm.

[0065] 2. Implementation steps

[0066] 1. The combined bottom stop is used as a pipe / rod column

[0067] Bottom retainer joint pipe string includes bridge plug, well gauge, support joint and tubing. From bottom to top, bridge plug, well gauge and support joint are connected in sequence. Oil pipe and support joint can also be connected between well gauge and support joint. The upper end is connected to the oil pipe.

[0068] The bottom block combined rod column includes a rod pump, a slide rod and a sucker rod, the lower end of the sucker rod is connected with the slide rod, and the lower end of the slide rod is connected with the rod type pump.

[0069] 1.1. Bottom baffle combined as pipe string combination (from bottom to top)

[0070] Bridge plug ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com