Humidity-interference-resistant super-hydrophobic fabric-based pressure sensor and preparation method thereof

A pressure sensor, super-hydrophobic technology, applied in the direction of plant fibers, textiles and paper, fibers repelling liquids, etc., can solve problems that are not conducive to wearing comfort, low air permeability of pressure sensors, high sensitivity and high precision are difficult to guarantee. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the superhydrophobic fabric-based pressure sensor of anti-humidity interference provided by the invention comprises the following steps:

[0031] S1. Ultrasonicize the fabric substrate in deionized water, sodium hydroxide solution and deionized water for a preset time, then take it out and dry it naturally.

[0032] In step S1, the fabric substrate is preferably cotton fabric or polyester-cotton blended fabric. Because the cotton fabric component in the cotton fabric or polyester-cotton blended fabric contains more active groups such as hydroxyl groups, it is helpful for the adsorption of subsequent conductive materials and can improve the adsorption fastness.

[0033] In step S1, the concentration of the sodium hydroxide solution is 1 wt% to 10 wt%, and the treatment time of the fabric substrate in the sodium hydroxide solution is 1 to 10 min. After being treated with sodium hydroxide solution, the impurities on the surface of the fabric are ...

Embodiment 1

[0045] A superhydrophobic fabric-based pressure sensor resistant to humidity interference, prepared by the following steps:

[0046] S1. Ultrasonic cleaning the cotton base cloth in deionized water, 5wt% sodium hydroxide solution, and deionized water for 5 minutes, then take it out and dry it naturally;

[0047] S2. Arrange the above-mentioned cotton base in a 5wt% PEDOT:PSS aqueous solution for ultrasonic treatment for 5min, then take it out and treat it in a 60°C oven for 15min to obtain a PEDOT:PSS conductive fabric;

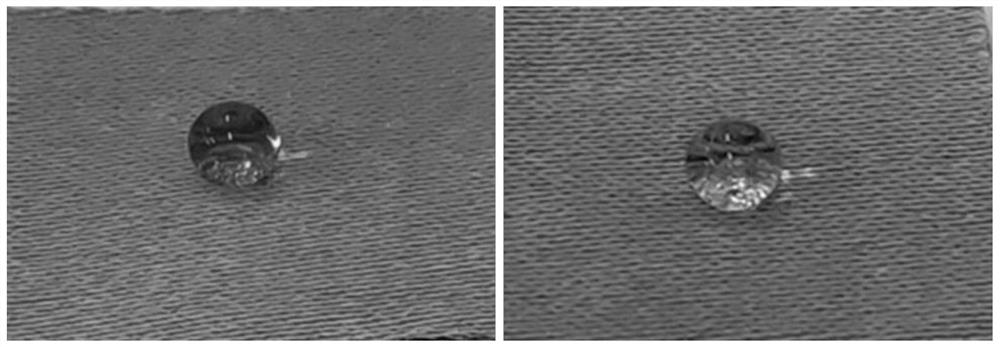

[0048] S3. Configuration of superhydrophobic TiO with 5wt% surface grafted long alkyl chains 2 dispersion, the above PEDOT:PSS conductive fabric was placed on this superhydrophobic TiO 2 Ultrasonic treatment in the dispersion for 1.5min, and then the obtained superhydrophobic conductive fabric was washed with deionized water, and then placed in a 60°C oven for 15min to obtain a superhydrophobic conductive fabric;

[0049] Among them, superhydrophobic TiO wi...

Embodiment 2-7 and comparative example 1-2

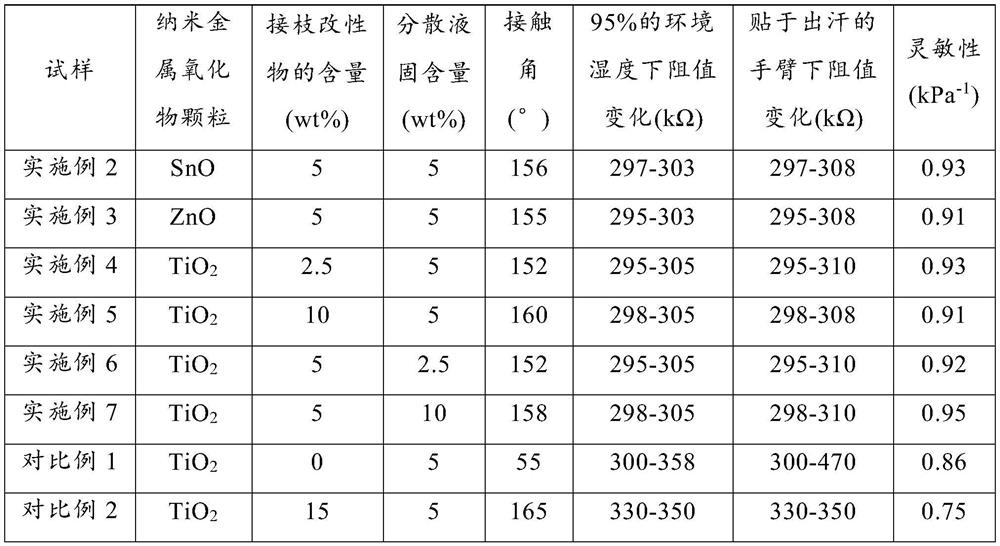

[0054] Compared with Example 1, the superhydrophobic fabric-based pressure sensor provided by Example 2-7 and Comparative Example 1-2 is different in that, in step S3, the nano-metal oxide particle type, grafted The content of the modified product and the solid content of the dispersion liquid are shown in Table 1, and the others are the same as in Example 1, and will not be repeated here.

[0055] Preparation conditions and performance test results of table 1 embodiment 2-7 and comparative example 1-2

[0056]

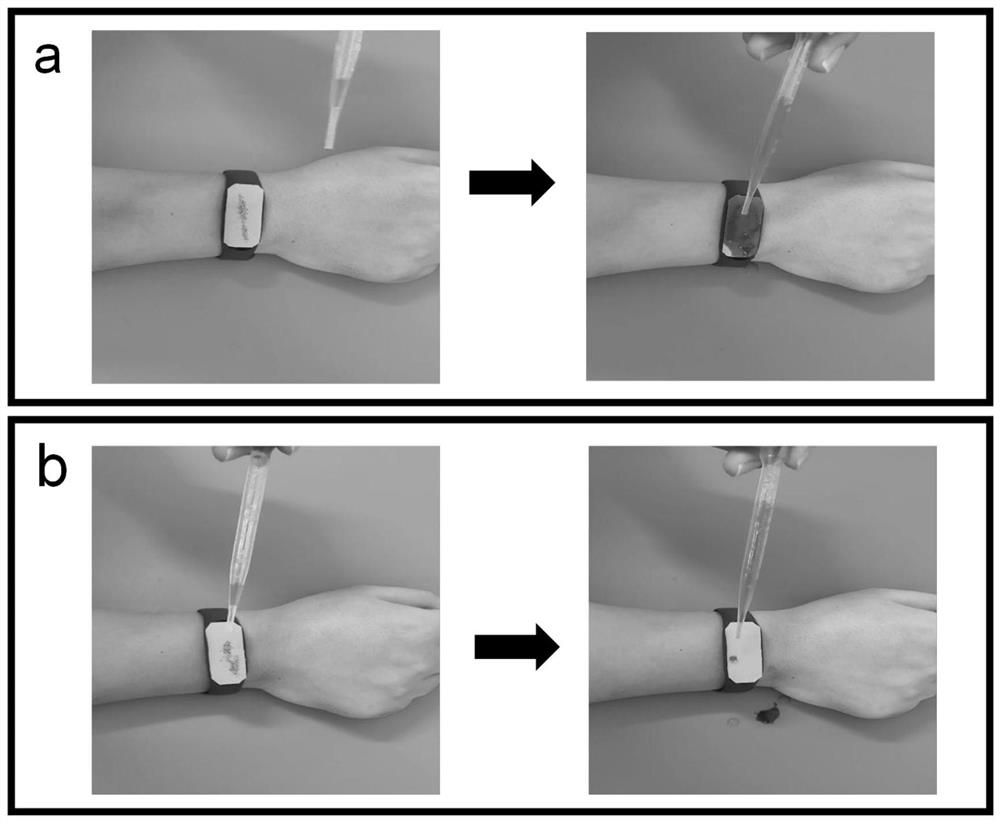

[0057] As can be seen from Table 1, the grafting of nanometer metal oxides can realize the superhydrophobicity of the material (the contact angle is above 150°); The contact angle of the metal oxide increases slightly, and the resistance value increases slightly. In the environment of high humidity and sweating, the resistance value remains basically stable, which makes the sensor have excellent anti-high humidity and sweat interference function. The non-graft-mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com