Low-temperature ultrasonic washing agent for black metal and preparation method of low-temperature ultrasonic washing agent

A ferrous metal and ultrasonic technology, applied in liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem that metals are prone to rust, the human body and the environment, ferrous metals have corrosion, and the medium and low temperature cleaning ability is insufficient To achieve the effect of improving emulsification and anti-rust function, outstanding electrolyte resistance, and low freezing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following clearly and completely describes the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

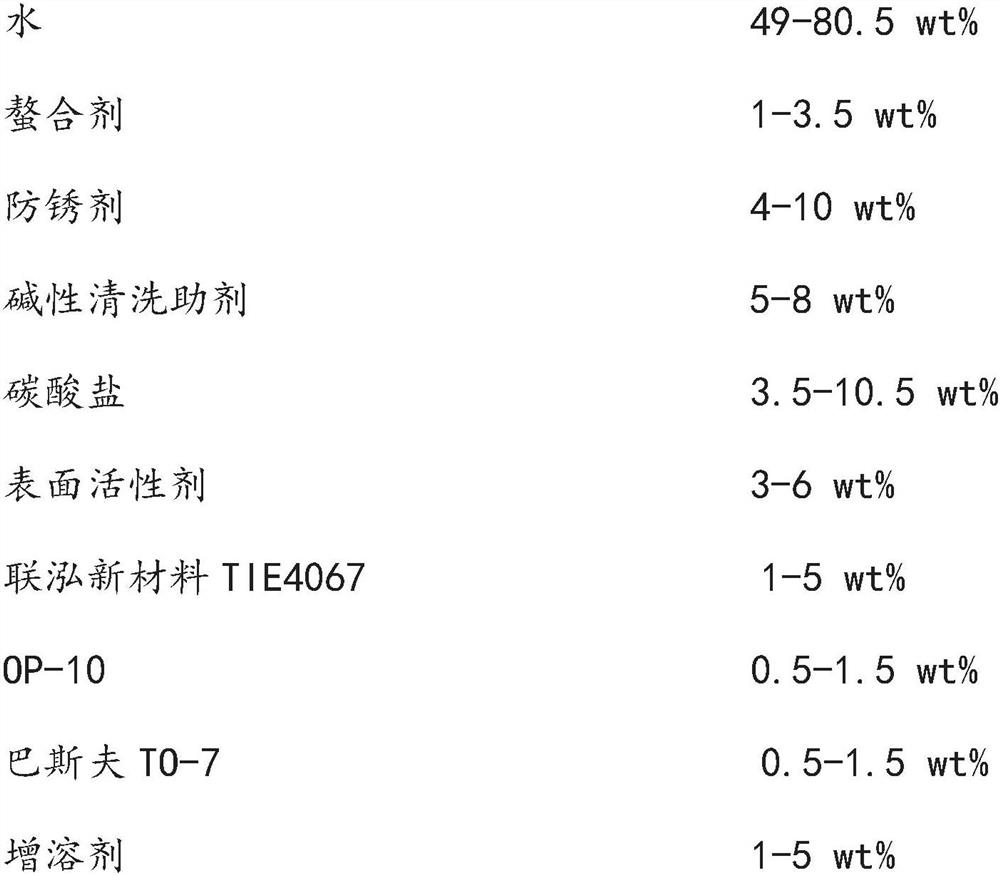

[0033] The invention provides a technical solution: a low-temperature ultrasonic cleaning agent for ferrous metals, comprising the following components:

[0034]

[0035]

[0036] The invention provides a technical solution: a low-temperature ultrasonic cleaning agent for ferrous metals, which mostly uses non-ionic surfactants, sodium gluconate and citric acid as chelating agents, and triethanolamine as alkaline cleaning aids, etc. It is a mixture composed of boric acid, mixed dibasic acid Corfree M1 and other rust inhibitors and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com