Decomposition agent with cellulose degradation and deodorization functions as well as preparation method and application thereof

A technology for degrading cellulose and decomposing agents, which is applied in the field of agricultural composting, can solve the problems of reducing odor emissions, accelerating compost maturity, and slow cellulose degradation, achieving good results, increasing fermentation speed, and improving compost quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

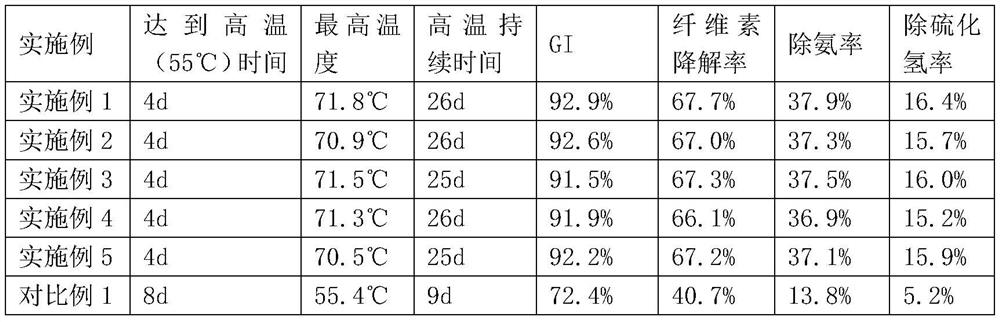

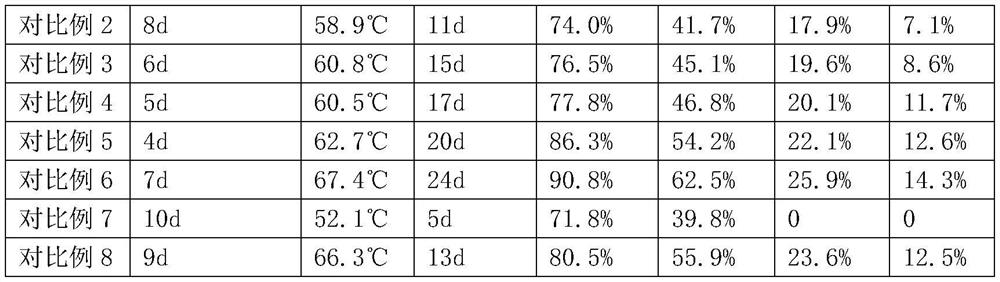

Examples

Embodiment 1

[0031] (1) Weigh 100 parts of liquid culture medium, 10 parts of protective agent and 2 parts of composite bacterial agent, put the protective agent and composite bacterial agent into the liquid medium and mix well to obtain a decomposing agent with degrading cellulose and deodorizing functions.

[0032] (2) Add the decomposing agent to the cow dung, adjust the water content to 60%, stir evenly, and pile it up for composting; the amount of the decomposing agent is 2% of the weight of the cow dung.

[0033] (3) Measure and record the temperature of the pile at ten o'clock in the morning every day. Place one 500mL beaker each containing boric acid and polyvinyl alcohol phosphoric acid on the top of the pile and in front, back, left, and right of the pile, and replace the solution every 24 hours. Use 2% boric acid to absorb ammonia, use polyvinyl ammonium phosphate to absorb hydrogen sulfide, stack for 30 days, and post-ripen for 10-15 days.

[0034] The liquid culture medium sol...

Embodiment 2

[0038] The method is the same as in Example 1, except that in step (1), 80 parts of liquid medium, 15 parts of protective agent and 4 parts of composite bacterial agent are taken.

Embodiment 3

[0040]The method is the same as in Example 1, except that 100 parts of liquid culture medium, 8 parts of protective agent and 3 parts of composite bacterial agent are taken in step (1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com