Low hydration heat and low density cement paste system for well cementation and preparation method and application thereof

A low-heat of hydration, low-density technology used in chemical instruments and methods, solid waste management, earth-moving drilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] 3. On the basis of above research result, the present invention further provides a kind of preparation method of low heat of hydration low density cement slurry system for well cementing, comprising the following steps:

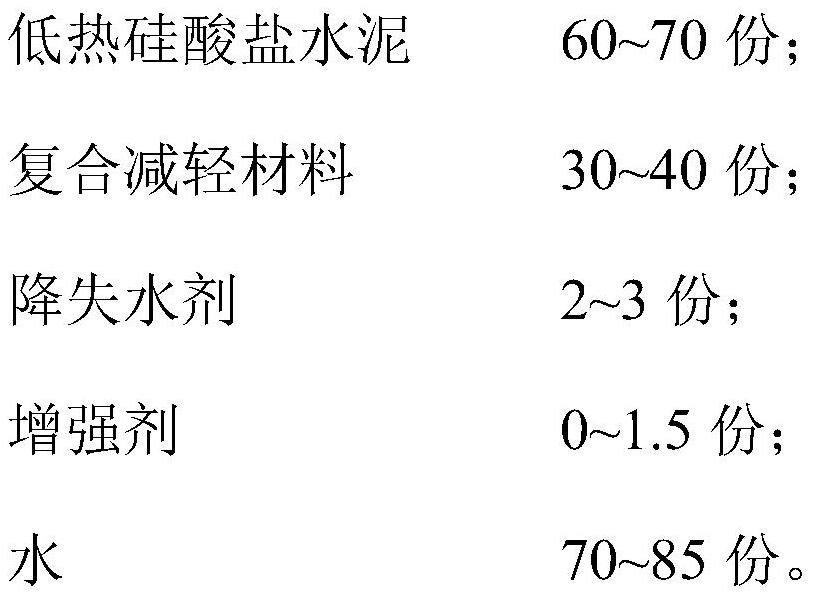

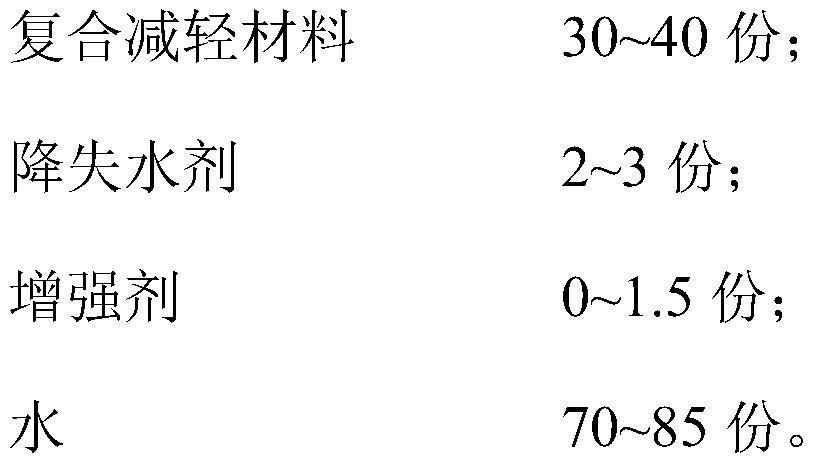

[0066] S1. Weigh raw materials according to the following parts by weight: 60-70 parts of low-heat Portland cement, 30-40 parts of composite lightening material, 2-3 parts of fluid loss reducer, 0-0.15 parts of retarder, 0 parts of reinforcing agent ~1.5 parts, 70~85 parts of water;

[0067] S2. Under normal temperature conditions, mix the low-heat Portland cement weighed in S1, composite lightening material, fluid loss reducing agent, retarder and reinforcing agent evenly to obtain mixed dry ash;

[0068] S3. Pour 70-85 parts of water into the mixing cup of the constant-speed agitator, turn on the constant-speed agitator, and pour the mixed dry ash obtained in S2 evenly within 0-15 seconds at a speed of 4000 rpm into the rotating slurry cup and conti...

Embodiment 1

[0076] This embodiment provides a cement slurry system with low heat of hydration and low density for well cementing, the formula of which is:

[0077]

[0078]

[0079] In the control group, the same amount of high-resistance G-grade oil well cement was used to replace the low-heat Portland cement, and the remaining components and dosage remained unchanged.

[0080] The experimental data of the low-heat-of-hydration low-density cement slurry system obtained in this embodiment are shown in Table 4 below:

[0081] Table 4 Density is 1.26g / cm 3 Experimental performance of low heat of hydration low density cement slurry system for well cementing

[0082]

Embodiment 2

[0084] This embodiment provides a cement slurry system with low heat of hydration and low density for well cementing, the formula of which is:

[0085]

[0086] In the control group, the same amount of high-resistance G-grade oil well cement was used to replace the low-heat Portland cement, and the remaining components and dosage remained unchanged.

[0087] The experimental data of the low-heat-of-hydration low-density cement slurry system obtained in this embodiment are shown in Table 5 below:

[0088] Table 5 Density is 1.31g / cm 3 Experimental performance of low heat of hydration low density cement slurry system for well cementing

[0089]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com