Lead zirconate titanate film for next-generation high-speed communication and preparation method and application thereof

A technology of lead zirconate titanate and high-speed communication, which is applied in the direction of coating, etc., can solve the problems of expensive equipment, limited application, harsh conditions, etc., and achieve the effect of easy adjustment of film thickness and size, huge application prospects, and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

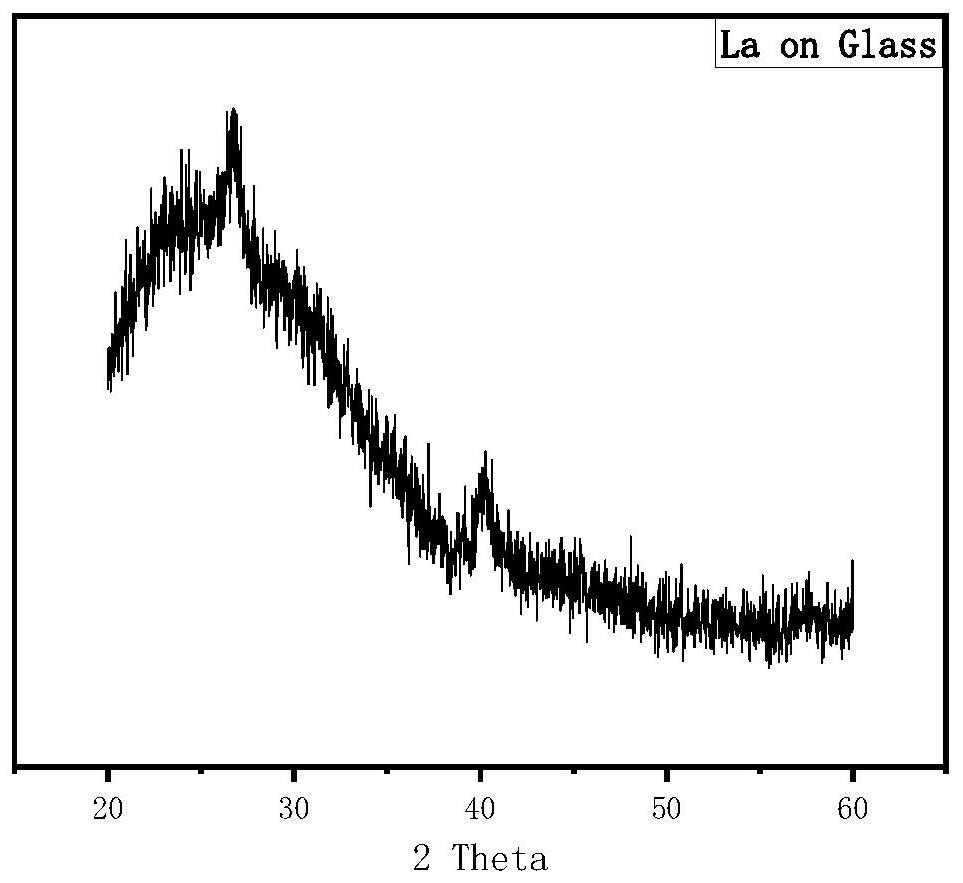

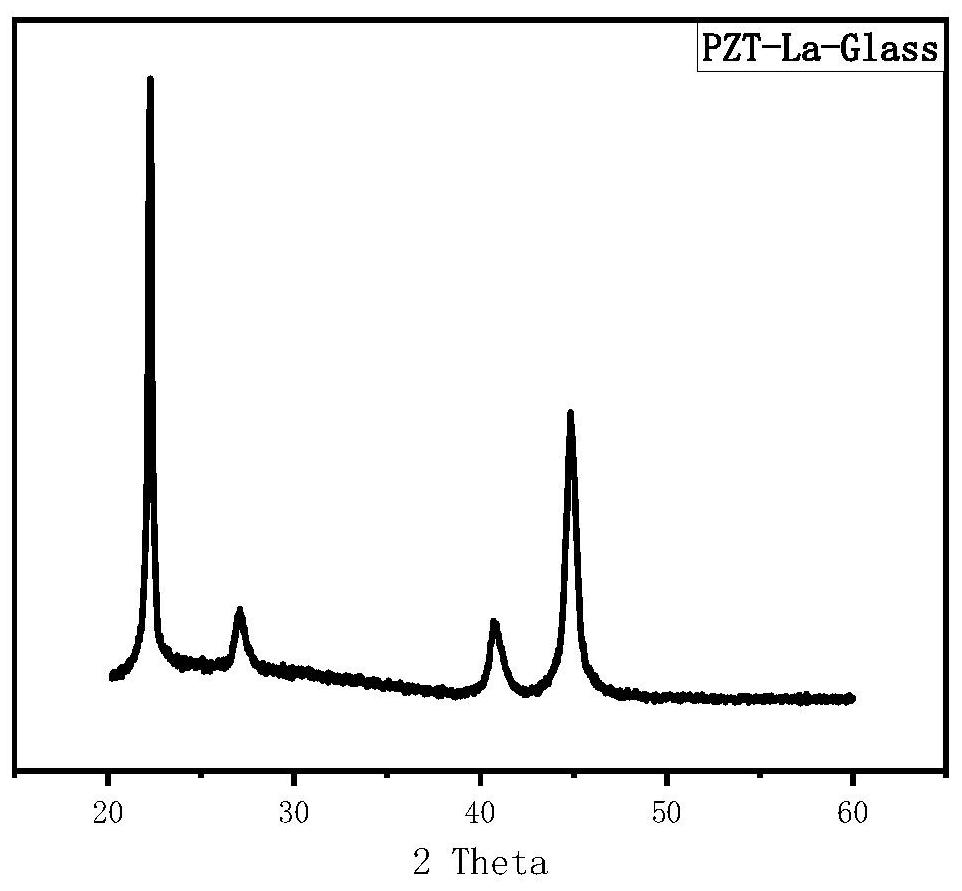

Embodiment 1

[0047] (1) Rinse the glass substrate with deionized water, then ultrasonically clean it with acetone, deionized water, and isopropanol for 10 minutes, and then dry it in a drying oven at 85°C for use;

[0048] (2) dissolving lanthanum nitrate in n-propanol solution to obtain a concentration of 0.02mol / L seed layer solution, sealed for use;

[0049] (3) Press Pb 1.0 Zr 0.2 Ti 0.8 o 3 Atomic ratio, lead acetate trihydrate is dissolved in diethylene glycol methyl ether to obtain lead acetate solution; then tetraethyl titanate is pressed by Pb 1.0 Zr 0.2 Ti 0.8 o 3 The atomic ratio is added dropwise in the lead acetate solution, and then press Pb 1.0 Zr 0.2 Ti 0.8 o 3The atomic ratio of zirconium isopropoxide solution was added dropwise, and stirred evenly; finally, 0.5% acetylacetone was added dropwise as a chelating agent, and fully stirred to obtain a chelated precursor solution; the concentration was 0.04mol / L, sealed and left standing, stand-by;

[0050] (4) The a...

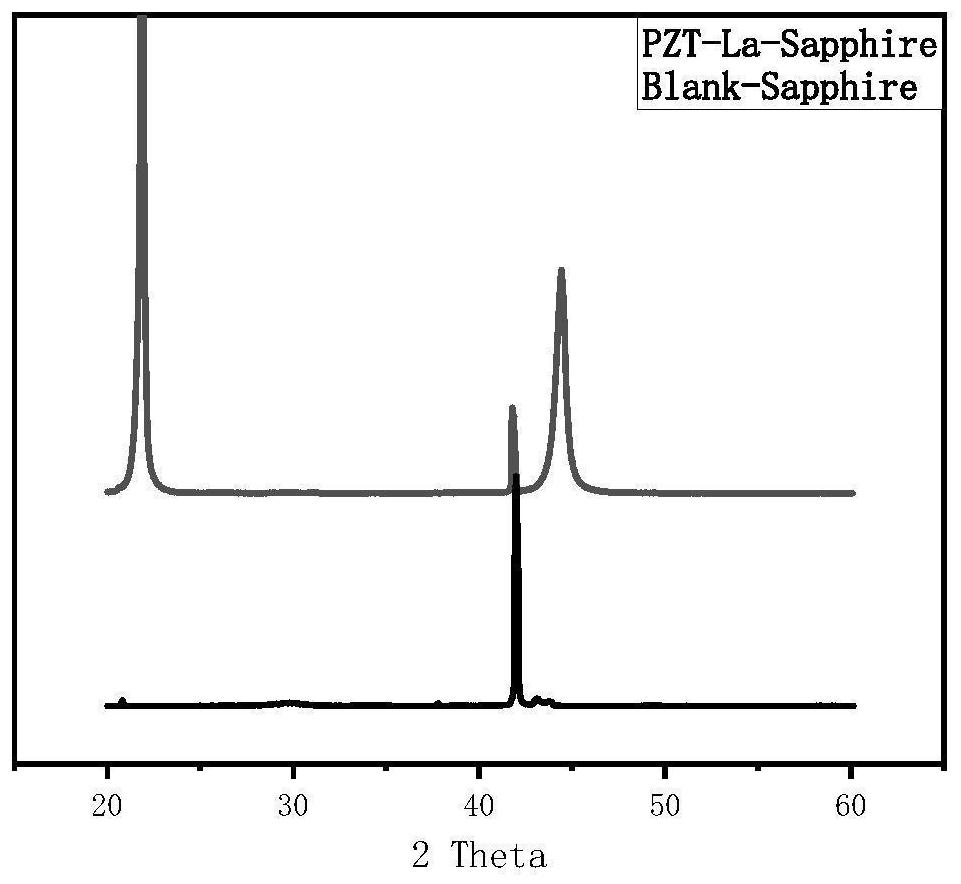

Embodiment 2

[0053] (1) Soak the sapphire substrate in concentrated sulfuric acid, rinse it with deionized water, then ultrasonically clean it with acetone, deionized water, and isopropanol for 10 minutes, then dry it in a drying oven at 85°C for use;

[0054] (2) neodymium nitrate is dissolved in ethylene glycol methyl ether solution, and the obtained concentration is 0.04mol / L neodymium nitrate seed layer solution, stand-by;

[0055] (3) Press Pb 1.1 Zr0. 65 Ti 0.35 o 3 Atomic ratio, lead acetate trihydrate is dissolved in ethylene glycol methyl ether, lead acetate solution; then isobutyl titanate is pressed by Pb 1.1 Zr0. 65 Ti 0.35 o 3 The atomic ratio is added dropwise to the lead acetate solution, and then press Pb 1.1 Zr0. 65 Ti 0.35 o 3 The atomic ratio of zirconium n-propoxide solution was added dropwise, and stirred evenly; finally, acetylacetone with a volume ratio of 2% was added dropwise as a chelating agent, and fully stirred to obtain a chelated PZT precursor solut...

Embodiment 3

[0059] (1) Rinse the glass substrate with deionized water, then ultrasonically clean it with acetone, deionized water, and isopropanol for 10 minutes, and then dry it in a drying oven at 85°C for use;

[0060] (2) dissolving praseodymium nitrate in ethylene glycol methyl ether solution to obtain a concentration of 0.1mol / L seed layer solution, sealed for use;

[0061] (3) Press Pb 1.2 Zr 0.52 Ti 0.48 o 3 Atomic ratio, lead acetate trihydrate is dissolved in ethylene glycol methyl ether to obtain lead acetate solution; then isopropyl titanate is pressed by Pb 1.2 Zr 0.52 Ti 0.48 o 3 The atomic ratio is added dropwise in the lead acetate solution, and then press Pb 1.2 Zr 0.52 Ti 0.48 o 3 The atomic ratio of zirconium isopropoxide solution was added dropwise, and stirred evenly; finally, a total of 5% acetylacetone was added dropwise as a chelating agent, and fully stirred to obtain a chelated precursor solution; the concentration was 0.4mol / L, sealed and left standing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electro-optic coefficient | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com