Membrane-method seawater desalination pretreatment system of offshore thickened oil thermal recovery steam-injection boiler

A technology for steam injection boiler and heavy oil thermal recovery, which is applied in seawater treatment, multi-stage water treatment, water/sewage treatment, etc. The effect of compact structure, strong impact resistance and stable water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: apply this technology at a certain platform in Bohai Sea. The average seawater temperature is 2.1°C, the average seawater turbidity is 105.6NTU, the average conductivity is 46000, and the average total dissolved solids (TDS) is 31.5g / L.

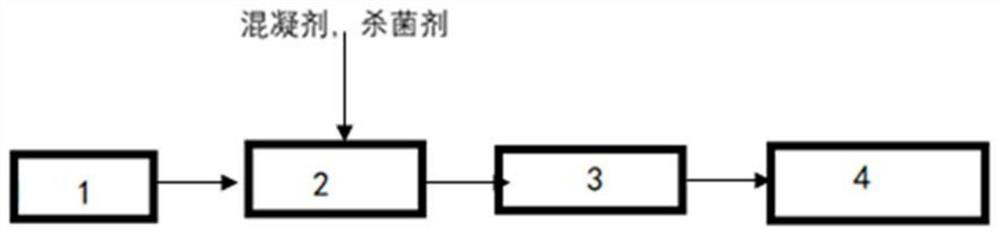

[0026] The membrane method seawater desalination pretreatment system of the offshore heavy oil thermal recovery steam injection boiler in this example, the processing steps are:

[0027] Sea water inflow 106.4m 3 / h, enter the settling tank and stay for 30 minutes to remove the sediment and large-size impurities in the seawater, and the water production is 104.27m 3 / h; the water produced in the settling tank is added with 0.55kg / h ferric chloride and 3kg / h chloramine through the pipeline mixer, and then enters the multi-media filter to remove flocs, and the water produced is 102.18m 3 / h; the produced water enters the ceramic ultrafiltration membrane system, the concentration ratio is 10, and the produced water volume ...

Embodiment 2

[0028] Embodiment 2: this technology is applied in a certain platform in Bohai Sea. The average seawater temperature is 13.5°C, the average seawater turbidity is 93.4NTU, the average conductivity is 45500, and the average total dissolved solids (TDS) is 32.1g / L.

[0029] The membrane method seawater desalination pretreatment system of the offshore heavy oil thermal recovery steam injection boiler in this example, the processing steps are:

[0030] Sea water inflow 105m 3 / h, enter the settling tank and stay for 30 minutes to remove the sediment and large-size impurities in the seawater, and the water production is 103m 3 / h; the water produced in the settling tank is added with 0.55kg / h ferric chloride and 3kg / h chloramine through the pipeline mixer, and then enters the multi-media filter to remove flocs, and the water produced is 101m 3 / h; the produced water enters the ceramic ultrafiltration membrane system, the concentration ratio is 10, and the produced water volume is ...

Embodiment 3

[0031] Embodiment 3: apply this technology at a certain platform in Bohai Sea. The average seawater temperature is 28.1°C, the average seawater turbidity is 81.4NTU, the average conductivity is 45300, and the average total dissolved solids (TDS) is 30.1g / L.

[0032] The membrane method seawater desalination pretreatment system of the offshore heavy oil thermal recovery steam injection boiler in this example, the processing steps are:

[0033] Sea water inflow 104m 3 / h, enter the settling tank and stay for 30 minutes to remove the sediment and large-size impurities in the seawater, and the water production is 102m 3 / h; the water produced in the settling tank is added with 0.55kg / h ferric chloride and 3kg / h chloramine through the pipeline mixer, and then enters the multi-media filter to remove flocs, and the water produced is 100m 3 / h; the produced water enters the ceramic ultrafiltration membrane system, the concentration ratio is 10, and the produced water volume is 90m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com