Mobile phone battery separation equipment

A technology for separating equipment and mobile phone batteries, which is applied in battery recycling, electronic waste recycling, solid waste removal, etc. It can solve problems such as low efficiency, easy frostbite of workers' hands, laborious manual lifting of batteries, etc., to reduce labor costs , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

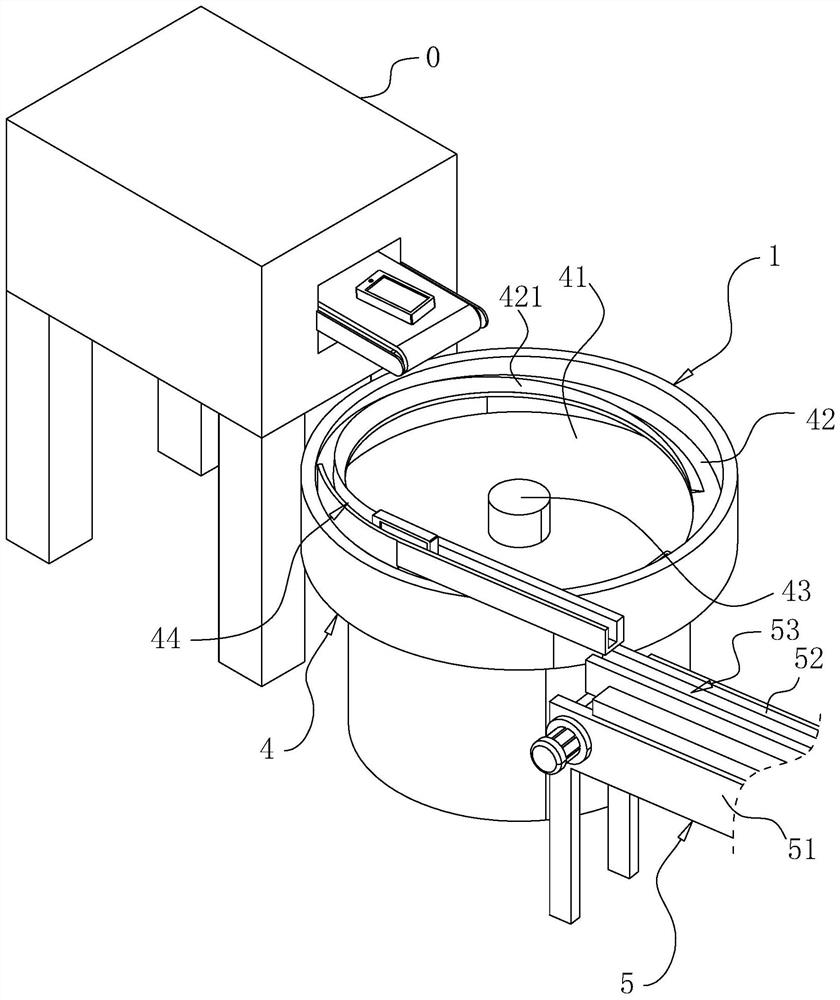

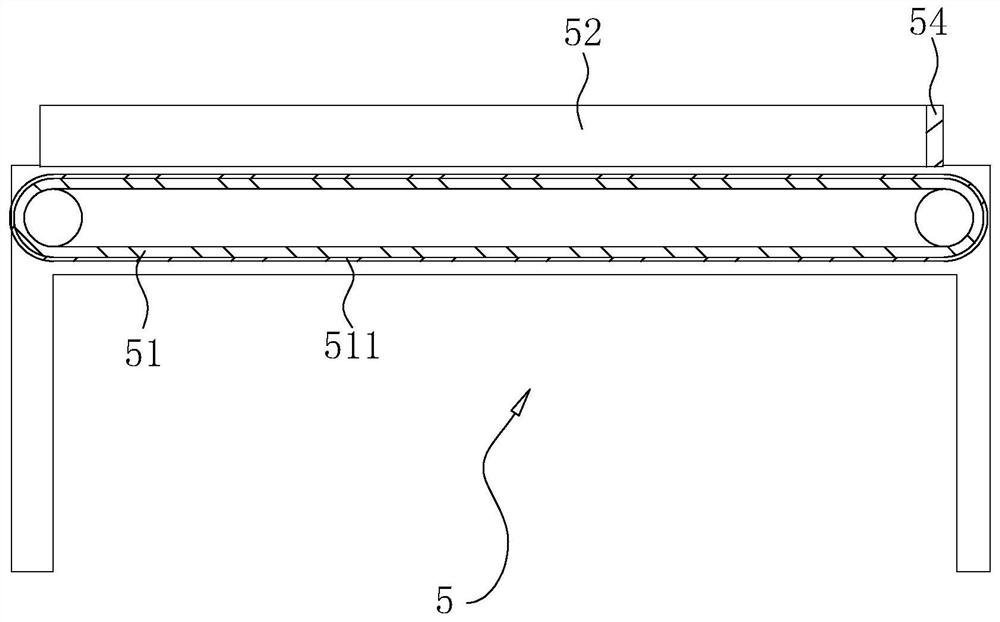

[0056] The following is attached Figure 1-6 The application is described in further detail.

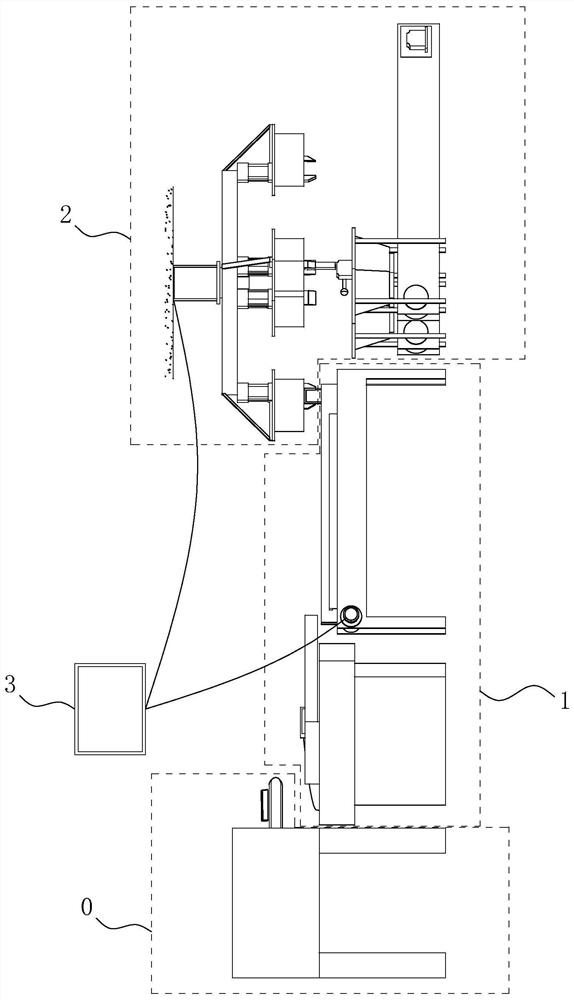

[0057] The embodiment of the present application discloses a mobile phone battery separation device. refer to figure 1 , including adjustment unit 1 , separation unit 2 and control unit 3 . The adjustment unit 1 is arranged at the discharge end of the low-temperature environment device 0, and is used to accept the discarded mobile phones that have passed through the low-temperature environment, and adjust the discarded mobile phones to a placement posture that is convenient for the separation unit 2 to separate the battery. The separation unit 2 is arranged at the outlet of the adjustment unit 1. After the adjustment unit 1 has adjusted the placement posture of the discarded mobile phone, the separation unit 2 separates the battery from the discarded mobile phone. The control unit 3 is used to control the operating states of the adjustment unit 1 and the separation unit 2 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com