Preparation method and application of copper-doped ferric oxide nanodisk

A technology of ferric oxide and nano-discs, applied in the field of water treatment, can solve the problems that are not suitable for the treatment and restoration of large-scale polluted water bodies, the activation efficiency is limited, and the energy consumption of treatment is increased, so as to achieve enhanced oxidation efficiency and utilization The effect of high efficiency, simple preparation process, and wide pH application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

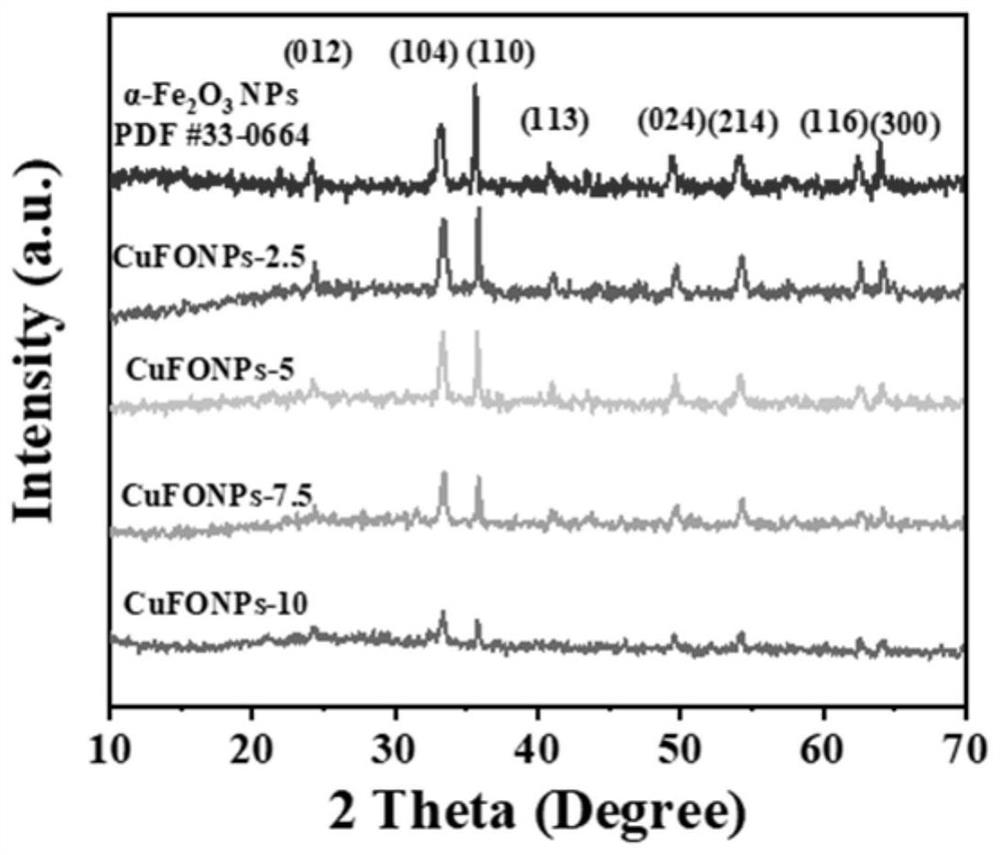

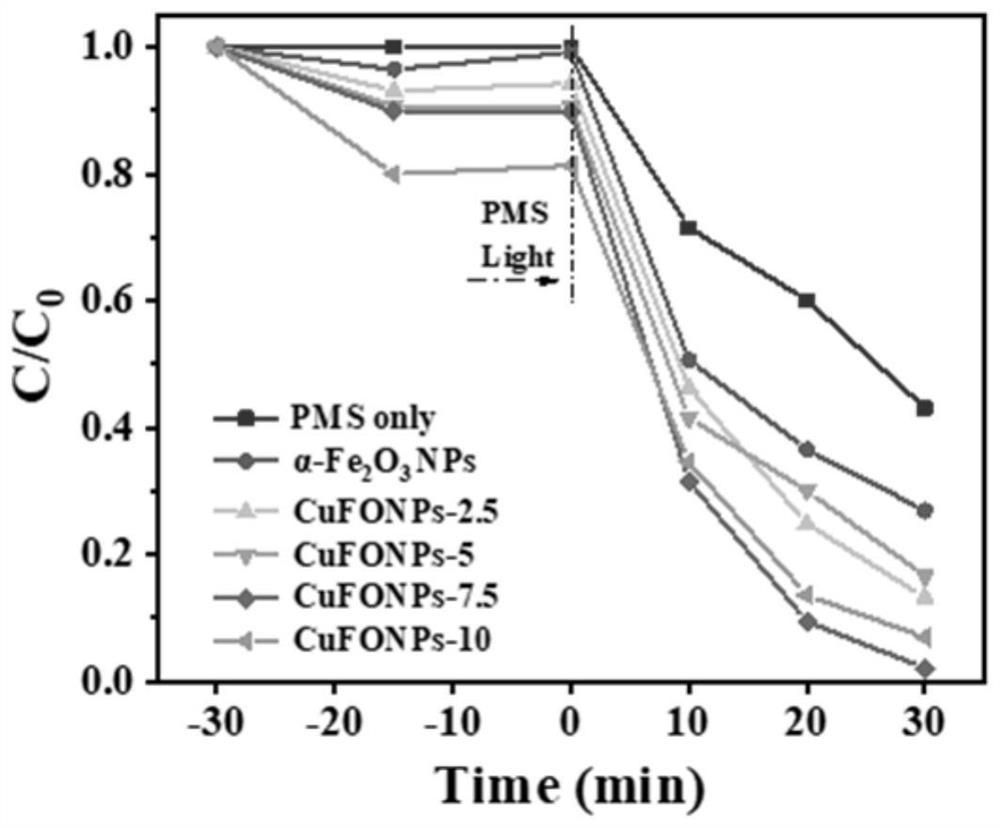

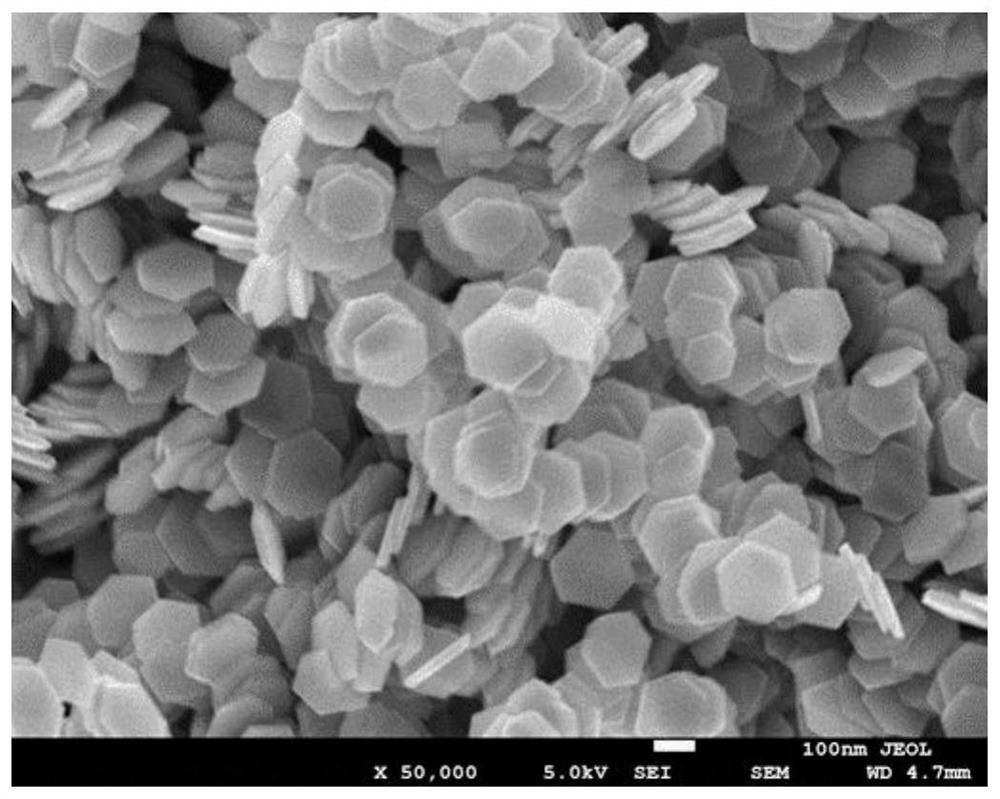

[0034] A method for preparing a copper-doped ferric oxide nano-disk, comprising the steps of:

[0035] 1) To the mixed solvent of 40mL ethanol and 2.8mL ultrapure water, add 0.01g CuCl 2 2H 2 O and 0.64 g FeCl 3 ·6H 2 O, at this time, Cu 2+ 2.5%, Fe 3+ Accounting for 97.5%, after completely dissolving, add 3.20g of sodium acetate and stir vigorously for 30min to obtain a homogeneous solution;

[0036] 2) Transfer the obtained homogeneous solution to a 90mL PVP reactor, seal it with a matching stainless steel sleeve, transfer it to a blast drying oven, set the reaction temperature at 180°C, and react for 12 hours. After the reaction, wait for the reactor to naturally Cool to room temperature;

[0037] 3) The reaction product obtained in step 2) was taken out, washed three times with ethanol and water respectively, the obtained precipitate was placed in a vacuum drying oven, and dried at 50°C for 12 hours to obtain copper-doped ferric oxide nanodiscs, which were recorded a...

Embodiment 2

[0040] A method for preparing a copper-doped ferric oxide nanodisk, comprising the steps of:

[0041] 1) To a mixed solvent of 40mL ethanol and 2.8mL ultrapure water, add 0.02g CuCl 2 2H 2 O and 0.62g FeCl 3 ·6H 2 O, at this time, Cu 2+ 5%, Fe 3+ Accounting for 95%, after completely dissolving, add 3.20g of sodium acetate and stir vigorously for 30min to obtain a homogeneous solution;

[0042] 2) Transfer the obtained homogeneous solution to a 90mL PVP reactor, seal it with a matching stainless steel sleeve, transfer it to a blast drying oven, set the reaction temperature at 180°C, and react for 12 hours. After the reaction, wait for the reactor to naturally Cool to room temperature;

[0043]3) The reaction product obtained in step 2) was taken out, washed three times with ethanol and water respectively, the obtained precipitate was placed in a vacuum drying oven, and dried at 50°C for 12 hours to obtain copper-doped ferric oxide nanodiscs, which were recorded as CuFONPs...

Embodiment 3

[0046] A method for preparing a copper-doped ferric oxide nano-disk, comprising the steps of:

[0047] 1) To a mixed solvent of 40mL ethanol and 2.8mL ultrapure water, add 0.03g CuCl 2 2H 2 O and 0.60 g FeCl 3 ·6H 2 O, at this time, Cu 2+ 7.5%, Fe 3+ Accounting for 92.5%, after completely dissolving, add 3.20g of sodium acetate and stir vigorously for 30min to obtain a homogeneous solution;

[0048] 2) Transfer the obtained homogeneous solution to a 90mL PVP reactor, seal it with a matching stainless steel sleeve, transfer it to a blast drying oven, set the reaction temperature at 180°C, and react for 12 hours. After the reaction, wait for the reactor to naturally Cool to room temperature;

[0049] 3) The reaction product obtained in step 2) was taken out, washed three times with ethanol and water respectively, the obtained precipitate was placed in a vacuum drying oven, and dried at 50°C for 12 hours to obtain copper-doped ferric oxide nanodiscs, which were recorded as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com