Refining method of methyltris (methylethylketoxime) silane

A technology of methyltributanone oxime and a purification method, which is applied in the chemical field and can solve problems such as the inability to use high-quality products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

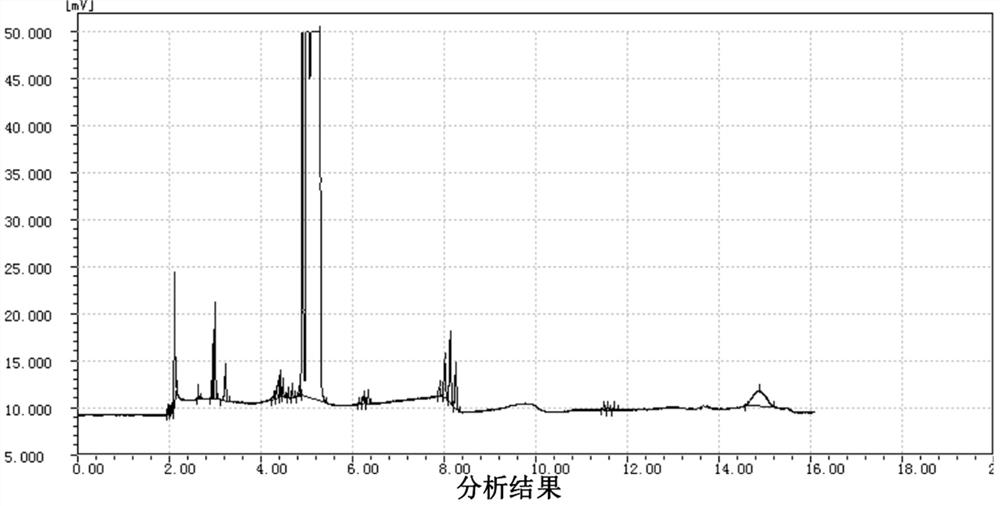

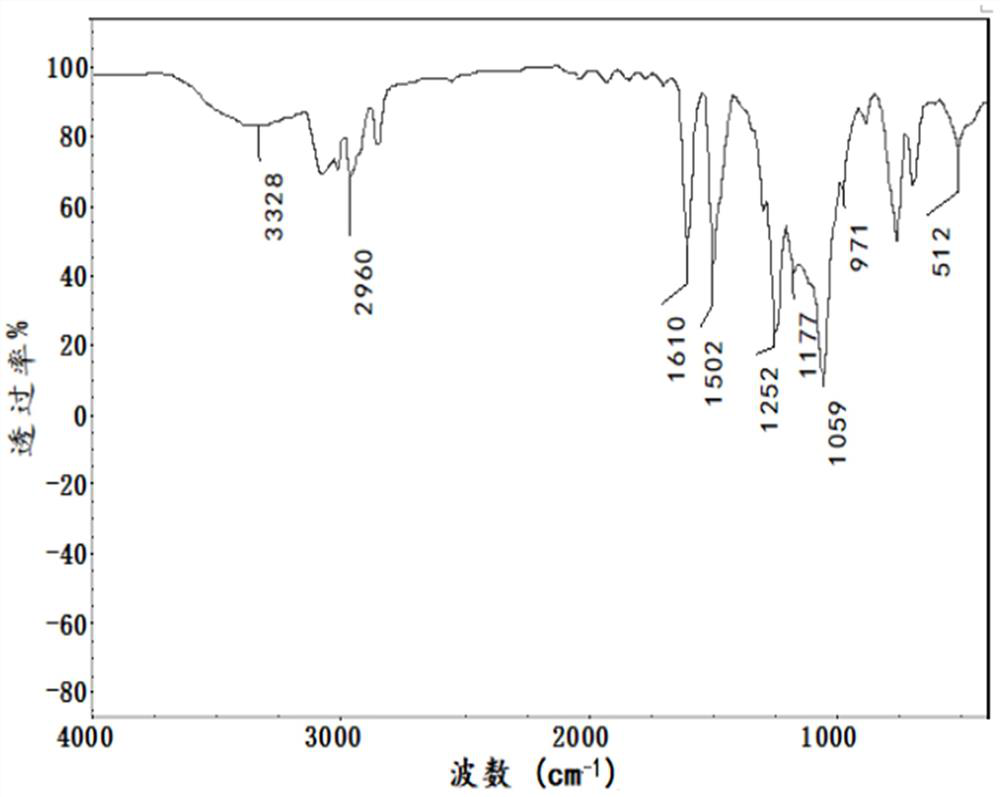

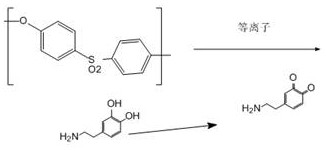

Image

Examples

Embodiment 1

[0036] A kind of refining method of methyl tributyl ketoxime silane, its operating steps are:

[0037] Add 100g of crude methyl tributylketoxime silane into the refining reaction kettle, blow the product with inert gas for 5min, then add 0.5g of modified adsorbent, raise the temperature to 40°C under the protection of inert gas, and stir the adsorption reaction After 1h, the temperature is lowered to 20°C, and then the material is pressure-filtered from the filter under the pressure of 0.1MPa inert gas, and the material is collected after the pressure-filtration is completed, and the refined methyl tributylketoxime silane can be obtained; its characteristics A hydroxyl adsorption filter membrane is used in the filter.

[0038]Described modified adsorbent is a kind of modified activated carbon adsorbent, and its preparation method is as follows:

[0039] Add 10g of activated carbon to 50g of pure water, control the temperature at 80°C, stir and wash for 30min, then filter and ...

Embodiment 2

[0048] A kind of refining method of methyl tributylketoxime base silane, its operating steps are:

[0049] Add 110g of crude methyl tributylketoxime silane into the refining reaction kettle, blow the product with inert gas for 8min, then add 2.5g of modified adsorbent, raise the temperature to 60°C under the protection of inert gas, and stir the adsorption reaction After 3 hours, the temperature is lowered to 25°C, and then the material is pressure-filtered from the filter under the pressure of 0.3MPa inert gas, and the material is collected after the pressure-filtration is completed, and the refined methyl tributylketoximosilane can be obtained; its characteristics A hydroxyl adsorption filter membrane is used in the filter.

[0050] Described modified adsorbent is a kind of modified activated carbon adsorbent, and its preparation method is as follows:

[0051] Add 15g of activated carbon to 60g of pure water, control the temperature at 90°C, stir and wash for 50min, then fi...

Embodiment 3

[0060] A kind of refining method of methyl tributylketoxime base silane, its operating steps are:

[0061] Add 120g of crude methyl tributylketoxime silane into the refining reaction kettle, blow the product with inert gas for 10min, then add 5g of modified adsorbent, raise the temperature to 80°C under the protection of inert gas, and stir the adsorption reaction for 5h After completion, the temperature is lowered to 30°C, and then the material is press-filtered from the filter under an inert gas pressure of 0.5MPa, and the material is collected after the press-filtration is completed, and the refined methyl tributylketoximosilane can be obtained; it is characterized in that A hydroxyl adsorption filter membrane is used in the filter.

[0062] Described modified adsorbent is a kind of modified activated carbon adsorbent, and its preparation method is as follows:

[0063] Add 20g of activated carbon to 80g of pure water, control the temperature at 100°C, stir and wash for 60m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com