Dissolving zone nitrate water automatic blending system

A technology for dissolving and nitrifying water, applied in the directions of dissolving, mixer accessories, mixers, etc., can solve the problems of low degree of automation, low efficiency of nitric water dispensing in the dissolving area, etc., and achieve the effect of preventing spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

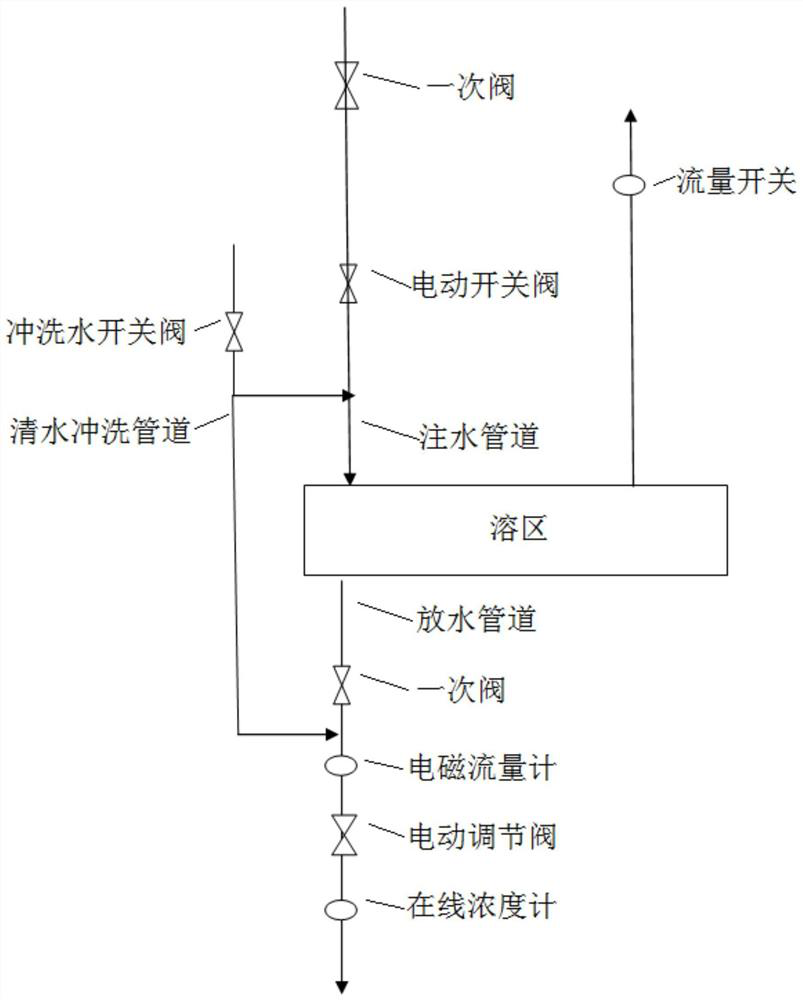

[0029] An automatic dispensing system for nitrate water in the melting zone, including a water injection pipeline connected to the water inlet of the melting zone, an electric on-off valve is installed on the water injection pipeline, a flow switch is installed at the emptying port of the melting zone, and a water discharge port of the melting zone is also connected with a The water discharge pipeline is equipped with an electromagnetic flowmeter, an electric control valve, and an online concentration meter in sequence, and a PLC control system is installed on the water discharge pipeline. The electric switch valve, flow switch, electromagnetic flowmeter, electric control valve, and online concentration meter are all connected to the PLC control system signal connection.

[0030]Through this setting, when performing water injection control in the melting zone, the PLC control system starts the electric on-off valve, and the water injection pipe injects water into the melting zo...

Embodiment 2

[0032] On the basis of Embodiment 1, both the water injection pipeline and the water discharge pipeline are connected with clean water flushing pipelines, and the clean water flushing pipeline is equipped with a flushing water switching valve, and the flushing water switching valve is connected to the PLC control system signal. Through this setting, the PLC control system activates the flushing water on-off valve on the clean water flushing pipeline, so that the water injection pipeline, water discharge pipeline, electric on-off valve, electromagnetic flowmeter, electric regulating valve, and online concentration meter in the melting zone are cleaned, and the nitric acid in the pipeline is eliminated. The water crystallizes, so that the equipment can reach the most ideal working state, and the normal operation of the deployment system will not be affected by the crystallization of nitrate water.

Embodiment 3

[0034] On the basis of the above embodiments, a primary valve is installed on the water injection pipeline at the front end of the electric on-off valve. With this arrangement, the water injection pipe can be prevented from leaking and clogging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com