Composite membrane material capable of efficiently separating gas and preparation method of composite membrane material

A technology for separating gases and composite materials, applied in separation methods, semi-permeable membrane separation, and dispersed particle separation, etc., can solve problems such as difficult preparation of film-forming materials and obstacles to the development of gas separation fields, and achieve low raw material costs and high commercial value , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0046] (1) Dissolve scandium trifluoromethanesulfonate in water to obtain solution A of 0.1mmol / L; mix 1,3,5-tris(4-aminophenyl)benzene (TAPB) and terephthalaldehyde (TP ) was dissolved in ethyl acetate to obtain solution B whose TAPB concentration was 4mmol / L and TP concentration was 6mmol / L. The rest refer to subscripts.

[0047] (2) Immerse the PSU membrane in solution A first, soak for 30 seconds, remove the water droplets on the surface with air, then soak in solution B, keep for 30 seconds; remove and dry the surface droplets, then repeat The above operation is performed 3 times.

[0048] (3) Immerse the membrane material in water for 3 minutes to fully wash, repeat three times; change to ethyl acetate and repeat three times, change to ethanol and repeat three times. Afterwards, the membrane material was dried in an oven at 60°C for 12 hours to obtain a TAPB-TP-CMP@PSU composite membrane material.

[0049]

Embodiment example 2

[0051] (1) Dissolve scandium trifluoromethanesulfonate in water to obtain 0.1mmol / L solution A; dissolve tetrakis(4-aminophenyl)methane (TABM) and terephthalaldehyde (TP) in ethyl acetate , a solution B with a concentration of TABM of 4 mmol / L and a concentration of TP of 8 mmol / L was obtained.

[0052] (2) Immerse the PSU membrane in solution A first, soak for 90 seconds, remove the water droplets on the surface with air, then soak in solution B, and keep for 90 seconds; remove and dry the surface droplets, and then repeat The above operation is performed 4 times.

[0053] (3) Immerse the membrane material in water for 3 minutes to fully wash, repeat three times; change to ethyl acetate and repeat three times, change to ethanol and repeat three times. Afterwards, the membrane material was dried in an oven at 60°C for 12 hours to obtain a TABM-TP-CMP@PSU composite membrane material.

[0054]

[0055] Performance Characterization

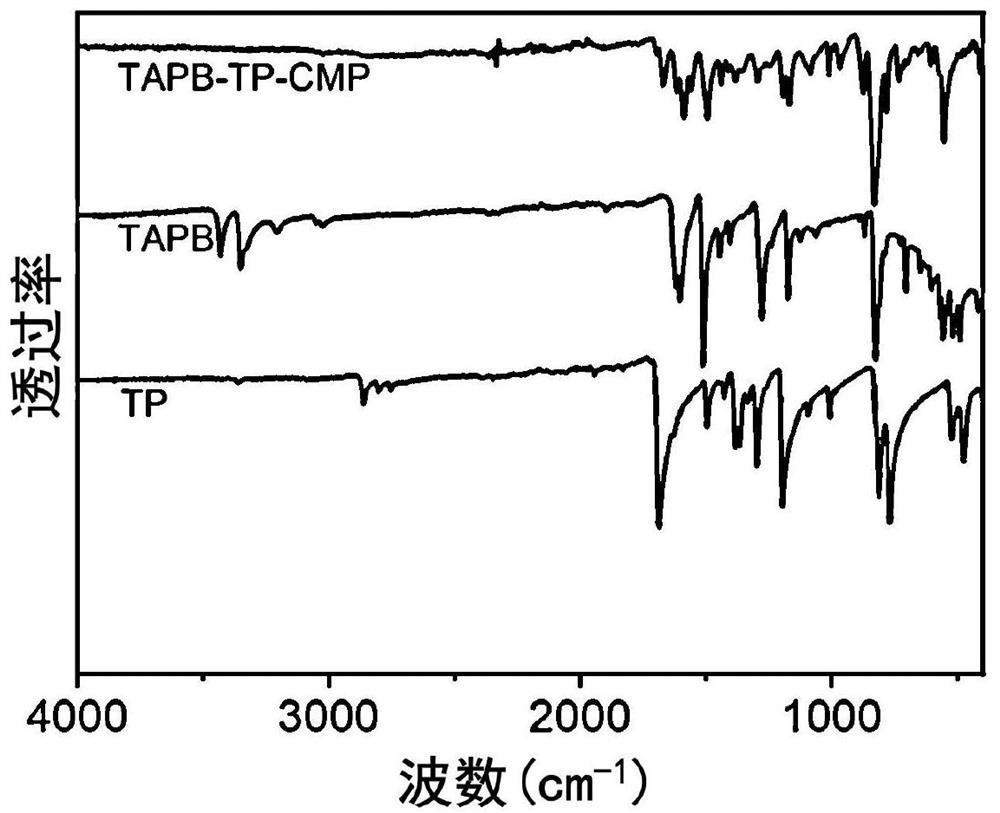

[0056] (1) Infrared spectrometer test re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com