Pole piece and lithium ion battery

A pole piece and pole ear technology, applied in secondary batteries, battery pack parts, non-aqueous electrolyte battery electrodes, etc., can solve the problems of poor cycle performance of lithium-ion batteries, improve charging risk, improve cycle performance, The effect of good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

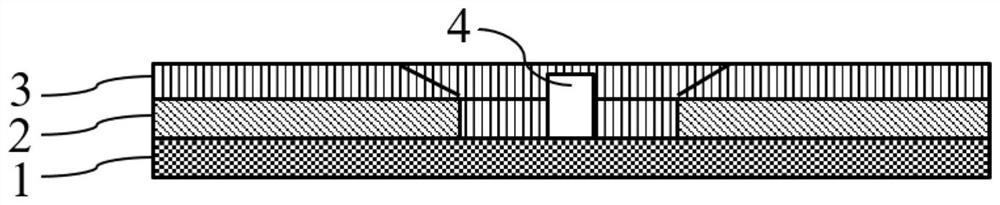

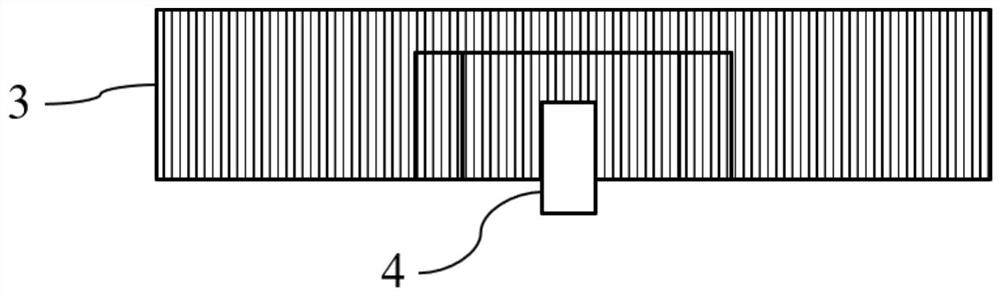

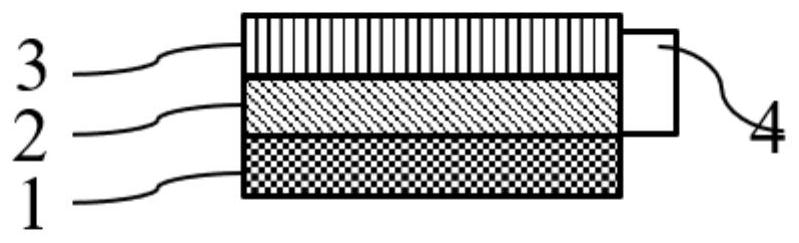

[0048] The pole piece provided by this embodiment is a positive pole piece, and the front view of its structure is as follows image 3 As shown, the top view is as Figure 4 As shown, the left view is as Figure 1c shown, where:

[0049] The current collector is aluminum foil with a width of 79mm;

[0050] The first groove has a width of 79mm and a length of 15mm;

[0051] The second groove has a width of 25mm and a length of 10mm;

[0052] The thickness of the first active layer is 10 μm, and the thickness of the second active layer is 80 μm;

[0053] The material used for the first active layer is a high-viscosity substance, including lithium cobaltate, conductive carbon, and polyvinylidene fluoride, wherein the molecular weight of polyvinylidene fluoride is 800,000, and the mass of polyvinylidene fluoride is the total mass of the first active layer 20% of.

Embodiment 2

[0055] The pole piece provided by this embodiment is a negative pole piece, and the front view of its structure is as follows Figure 2a As shown, the top view is as Figure 4 As shown, the left view is as Figure 1c shown, where:

[0056] The current collector is copper foil with a width of 81mm;

[0057] The first groove has a width of 81mm and a length of 50mm;

[0058] The second groove has a width of 25mm and a length of 10mm;

[0059] The thickness of the first active layer is 50 μm, and the thickness of the second active layer is 50 μm;

[0060] The active material used in the second active layer is graphite, the average particle size of graphite is 15 μm, and the degree of graphitization is 94%.

Embodiment 3

[0062] The pole piece provided by this embodiment is a negative pole piece, and the front view of its structure is as follows image 3 As shown, the top view is shown in Figure 4, and the left view is shown in Figure 1c shown, where:

[0063] The current collector is copper foil with a width of 81mm;

[0064] The first groove has a width of 81mm and a length of 50mm;

[0065] The second groove has a width of 25mm and a length of 10mm;

[0066] The thickness of the first active layer is 30 μm, and the thickness of the second active layer is 70 μm;

[0067] The active material used in the second active layer is graphite, the average particle size of graphite is 15 μm, and the degree of graphitization is 94%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com