Preparation method of gas sensor and gas sensor

A gas sensor and N-type semiconductor technology, applied in the direction of semiconductor devices, electrical components, material resistance, etc., can solve the problems of increasing device on-resistance and operating voltage, reducing device performance, and deteriorating the quality of nanowire crystals, etc., to achieve low Effect of operating voltage and low contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A method for preparing a gas sensor provided by the present invention and specific implementations of the gas sensor will be described in detail below with reference to the accompanying drawings.

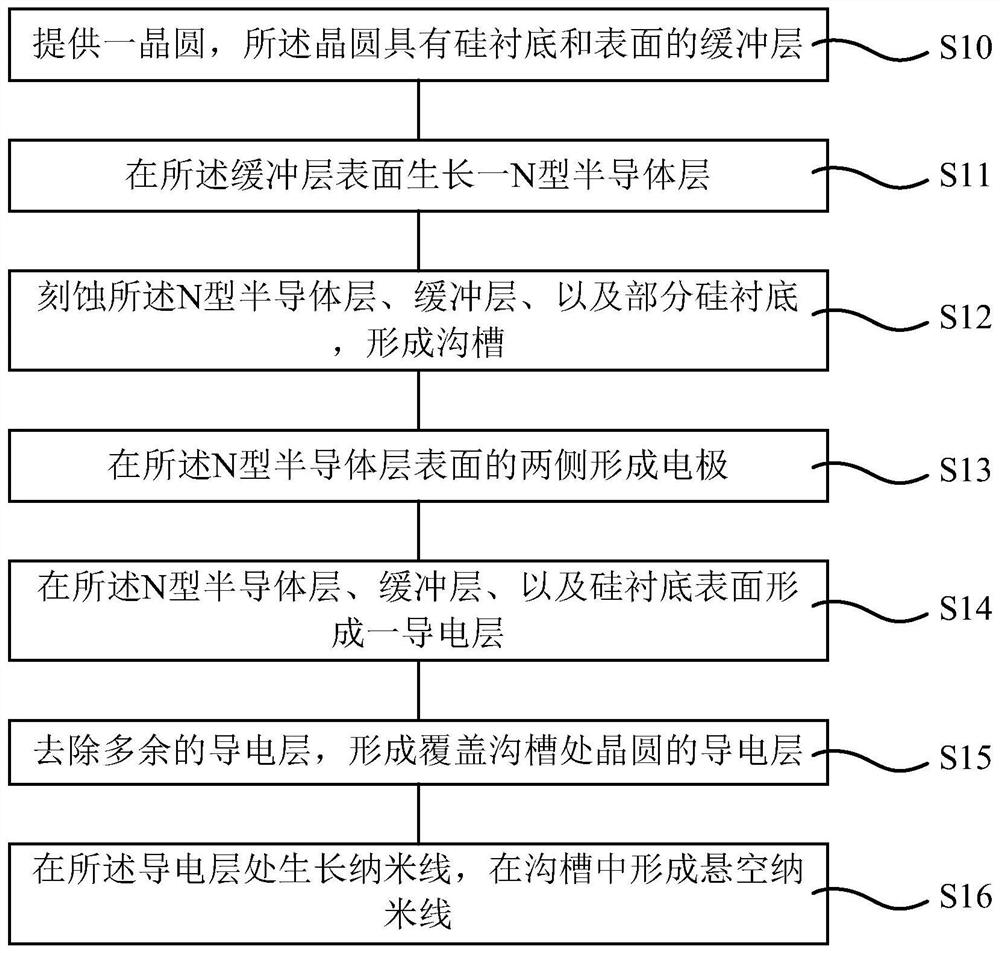

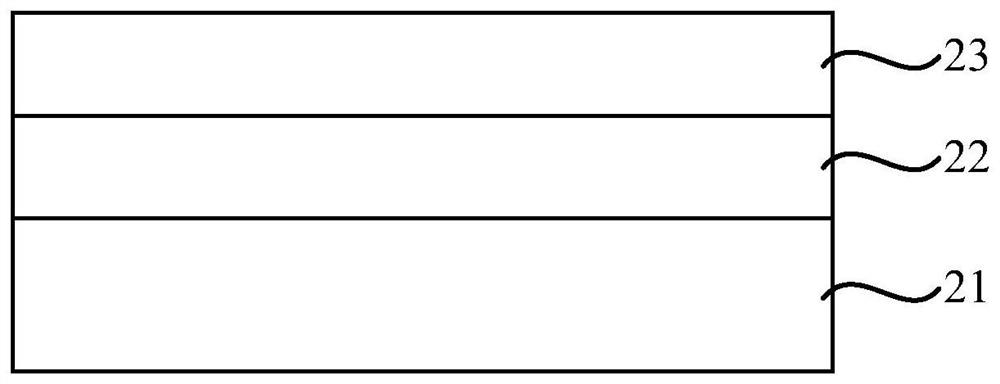

[0014] attached figure 1 Shown is a schematic diagram of the steps of a specific embodiment of the present invention, including: step S10, providing a wafer, the wafer has a silicon substrate and a buffer layer on the surface; step S11, growing a N on the surface of the buffer layer type semiconductor layer; step S12, etching the N-type semiconductor layer, buffer layer, and part of the silicon substrate to form a trench; step S13, forming electrodes on both sides of the surface of the N-type semiconductor layer; step S14, The N-type semiconductor layer, the buffer layer, and the surface of the silicon substrate form a conductive layer; step S15, remove the redundant conductive layer, and form a conductive layer covering the wafer at the trench; step S16, grow on the conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com