An engine thermal management system and method

A heat management system and engine technology, applied to engine components, combustion engines, machines/engines, etc., can solve problems such as overcooling and partial cooling, and achieve the effects of reducing working pressure, saving energy, and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

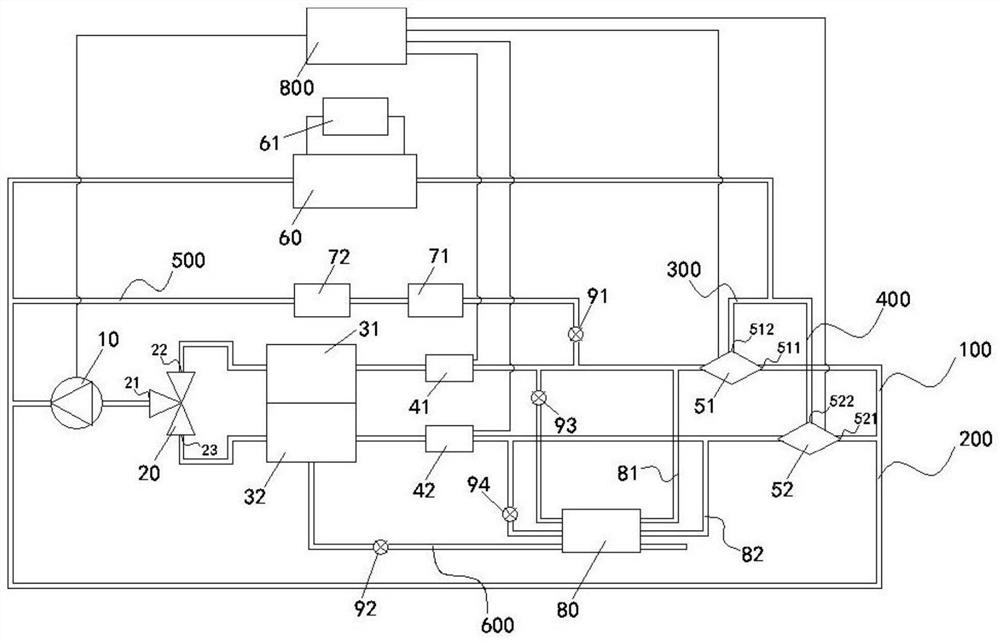

[0040] please combine figure 1 , this embodiment provides an engine thermal management system, including a coolant pump 10, a three-way valve 20, a cylinder head cooling jacket 31, a cylinder block cooling jacket 32, a first temperature sensor 41, a second temperature sensor 42, a first section The thermostat 51, the second thermostat 52, the radiator 60 and the control unit 800; the first temperature sensor 41 can detect the temperature of the coolant passing through the cylinder head cooling jacket 31, and the second temperature sensor 42 can detecting the temperature of the coolant passing through the cylinder cooling jacket 32;

[0041] The three-way valve 20 includes a three-way valve inlet 21, a three-way valve first outlet 22, and a three-way valve second outlet 23. The three-way valve inlet 21 is connected to the liquid outlet end of the coolant pump 10, so The first outlet 22 of the three-way valve is connected to the cylinder head cooling jacket 31, the cylinder hea...

Embodiment 2

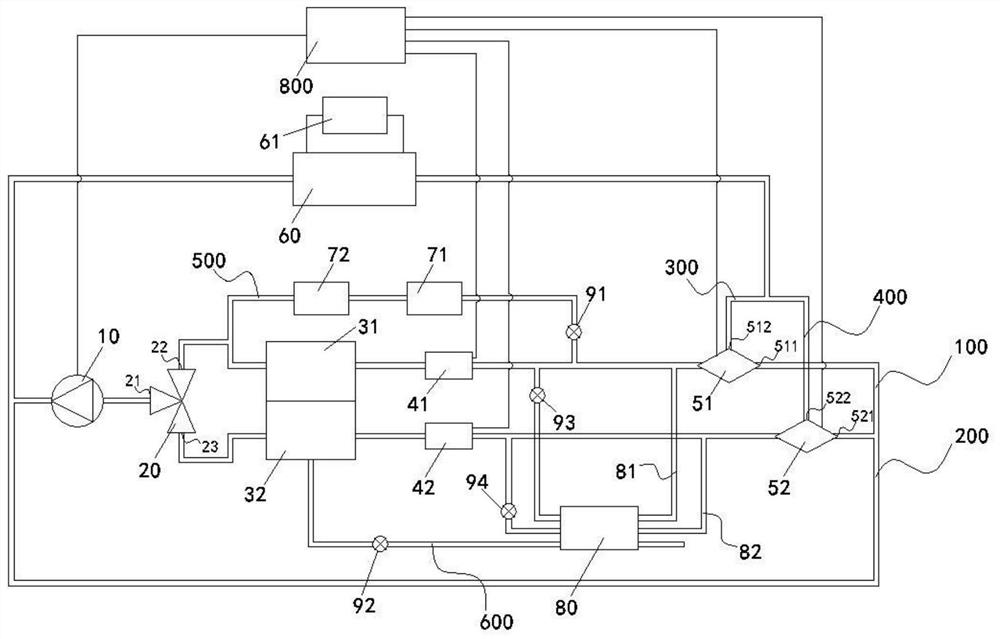

[0060] please combine figure 2 , This embodiment is an engine thermal management system. The difference from Embodiment 1 is that the intercooler 72 is connected to the liquid inlet end of the cylinder head cooling jacket 31. The cylinder head cooling jacket 31, the first The temperature sensor 41 , the temperature regulator 71 and the intercooler 72 constitute the engine intake heat management branch 500 .

[0061] Of course, the intercooler 72 may be connected at other positions besides the above-mentioned connection positions, and only needs to play the role of leading out the cooling liquid in the engine intake heat management branch 500 .

[0062] The working principle and beneficial effects of an engine passenger management system provided in this embodiment are the same as those in Embodiment 1, which will not be repeated here.

Embodiment 3

[0064] This embodiment provides an engine thermal management method, which is used in any one of the engine thermal management systems provided in the above embodiments, including:

[0065] a first temperature sensor collects a first temperature, where the first temperature is the temperature of the cooling liquid after passing through the cylinder head cooling jacket, and sends the first temperature to the control unit;

[0066] The control unit compares the first temperature with a preset first temperature threshold, and when the first temperature is less than or equal to the first temperature threshold, the control unit controls the first thermostatic valve The first connection port is turned on, and the first cylinder head heat dissipation circuit is used to thermally manage the engine cylinder head. When the first temperature is greater than the first temperature threshold, the control unit controls the first throttle temperature The valve conducts the second connection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com