Method for preventing metal materials from being scratched on tube wall in tubular annealing furnace

A technology of metal materials and annealing furnaces, applied in the direction of metal processing equipment, furnaces, furnace types, etc., can solve the problem of the same force on the outer surface of the metal strip body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

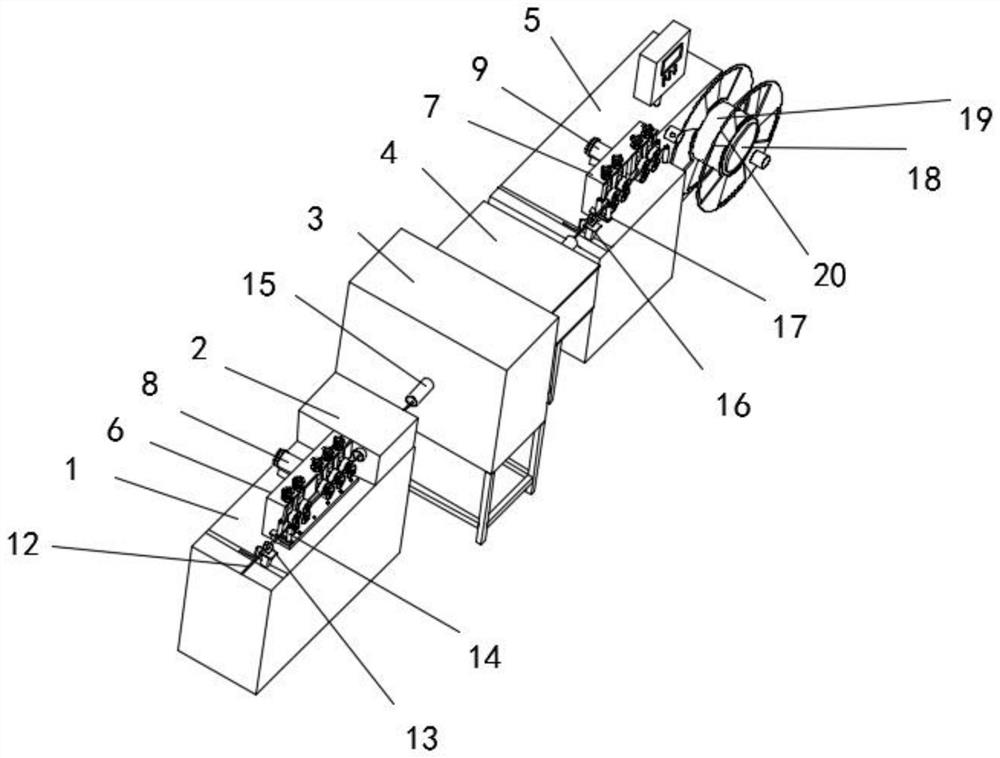

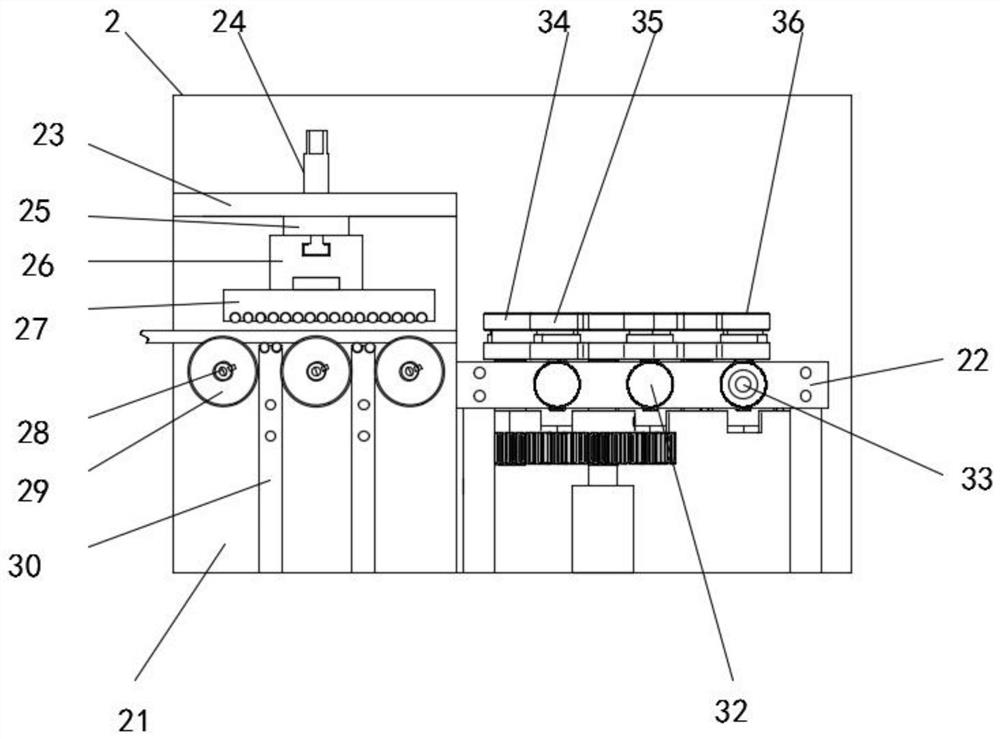

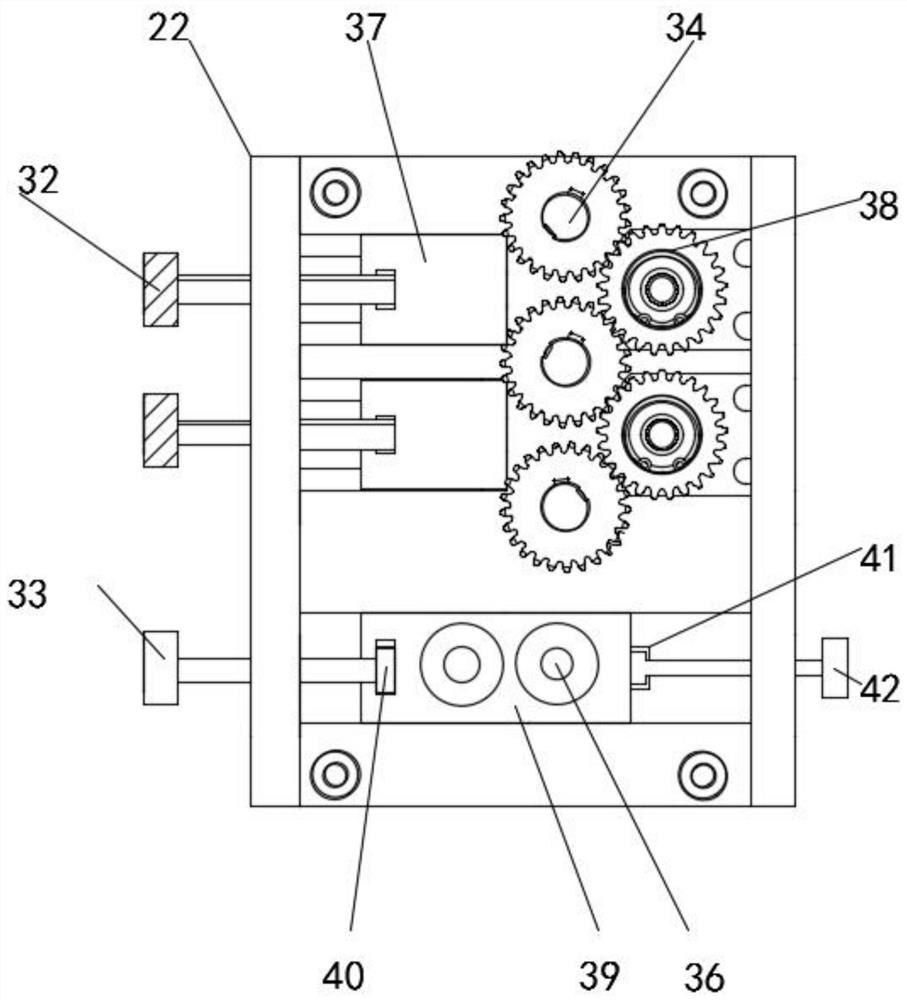

[0034] Such as Figure 1-5 As shown, the method for preventing metal material from scratching the tube wall in the tube annealing furnace comprises the following steps:

[0035] Step 1: Take a roll of strip-shaped metal material, which is the metal strip body 12;

[0036] Step 2: Pass the metal bar body 12 through the inside of the first ring encoder 13 into the annealing device, and control the first ring encoder 13 to slide on the upper surface of the first support base 1 through the bar-shaped groove 1, so that the metal bar body 12 Pass through the first limit stop post 14 to the position between the first tension wheel 66 and the second tension wheel 68, start the first drive motor 8, and drive the third rotating rod 70 to rotate, the outer surface of the third rotating rod 70 The socketed gear four is engaged with the gear three socketed on the outer surface of the second rotating rod 67 near the rear end, thereby driving the second rotating rod 67 to rotate, and then d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com