Road water stabilizing material and preparation method thereof

A water-stabilized material and road technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high production energy consumption, miscellaneous components, poor quality stability, etc., and achieve high early strength, The production process is simple and the maintenance period is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

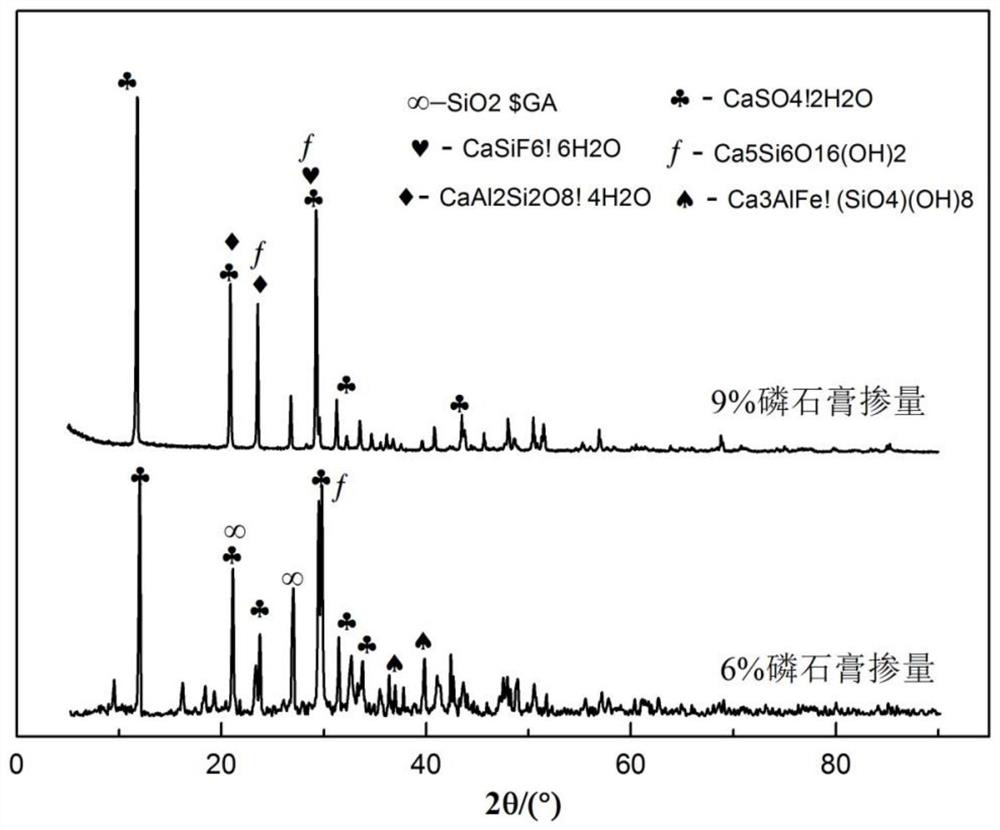

Embodiment 1

[0038] Embodiment 1: Prepare medium-grained soil water-stabilizing material with cement-stabilized steel slag-gravel-phosphogypsum, wherein the dosage of phosphogypsum is 6%, and it is carried out according to the following steps:

[0039] Step 1. Weigh about 487.7g of steel slag in the range of particle size 4.65-20.0mm, about 709.3g of steel slag in the range of particle size 0.5-4.65mm, about 133.0g of phosphogypsum in the range of particle size 0-0.15mm, add about 76ml of water, stir and mix for 2 hours ;

[0040] Step 2: Weigh 487.7g of gravel with a particle size of 4.65-20.0mm, soak in water for 2 hours;

[0041] Step 3: Weigh 133g of cement, pour it into a mortar mixer together with the steel slag and phosphogypsum powder that have been stuffed in step 1, and mix and stir for 2 minutes;

[0042] Step 4: Add 133ml of water to the mixture in Step 3, mix and stir for 2 minutes;

[0043] Step 5. Pour the crushed stones completed in step 2 into the mixture in step 4, and ...

Embodiment 2

[0048] Embodiment 2: Prepare medium-grained soil water-stabilizing material with cement-stabilized steel slag-gravel-phosphogypsum, wherein the dosage of phosphogypsum is 9%, and it is carried out according to the following steps:

[0049] Step 1. Weigh 487.7g of steel slag in the range of 4.65-20.0mm in particle size, 642.7g of steel slag in the range of 0.5-4.65mm in particle size, 199.3g of phosphogypsum in the range of 0-0.15mm in particle size, add 76ml of water and stir and mix for 2 hours;

[0050] Step 2: Weigh 487.7g of gravel with a particle size of 4.65-20.0mm, soak in water for 2 hours;

[0051]Step 3: Weigh 133g of cement, pour it into a mortar mixer together with the steel slag and phosphogypsum powder that have been stuffed in step 1, and mix and stir for 2 minutes;

[0052] Step 4: Add 133ml of water to the mixture in Step 3, mix and stir for 2 minutes;

[0053] Step 5. Pour the crushed stones completed in step 2 into the mixture in step 4, and mix and stir fo...

Embodiment 3

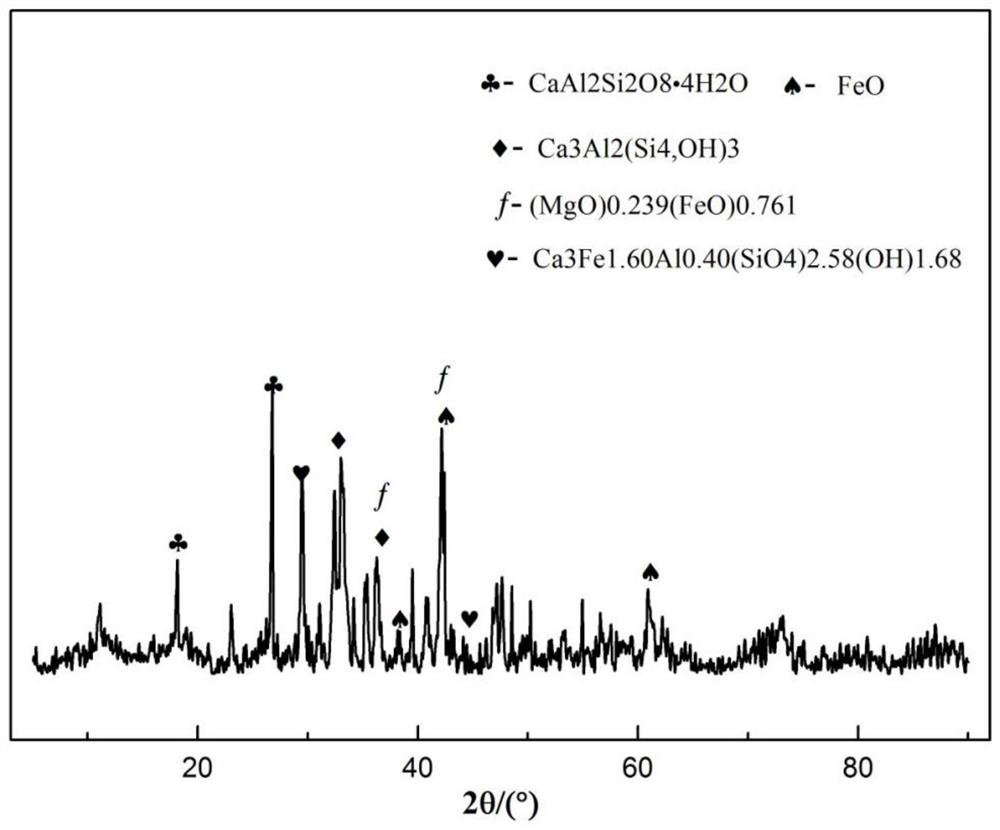

[0058] Embodiment 3: Prepare fine-grained soil water-stabilizing material with cement-stabilized steel slag-phosphogypsum, wherein the dosage of phosphogypsum is 3%, and it is carried out according to the following steps:

[0059] Step 1. Weigh 25.2g of steel slag within the range of 0-0.3mm, 63.0g of steel slag within the range of 0.3-0.8mm, 63.0g of steel slag within the range of 0.8-3.0mm, and 52.2g of steel slag within the range of 3-4.65mm. , 6.3g of phosphogypsum within the range of 0-0.15mm, add 11.3ml of water and stir and mix for 2 hours;

[0060] Step 2: Weigh 12.6g of cement, pour it into a mortar mixer together with the steel slag and phosphogypsum powder that have been stuffed in step 1, and mix and stir for 3 minutes;

[0061] Step 3: Pour the water stabilizer mixed in Step 2 into the mold, use a concrete vibrating tamping rod or a manual tamping rod for preliminary vibration, and use a press with a range of not less than 2000KN to pressurize at a loading speed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com