Method and device for improving treatment efficiency of anaerobic reactor in pharmaceutical wastewater treatment process

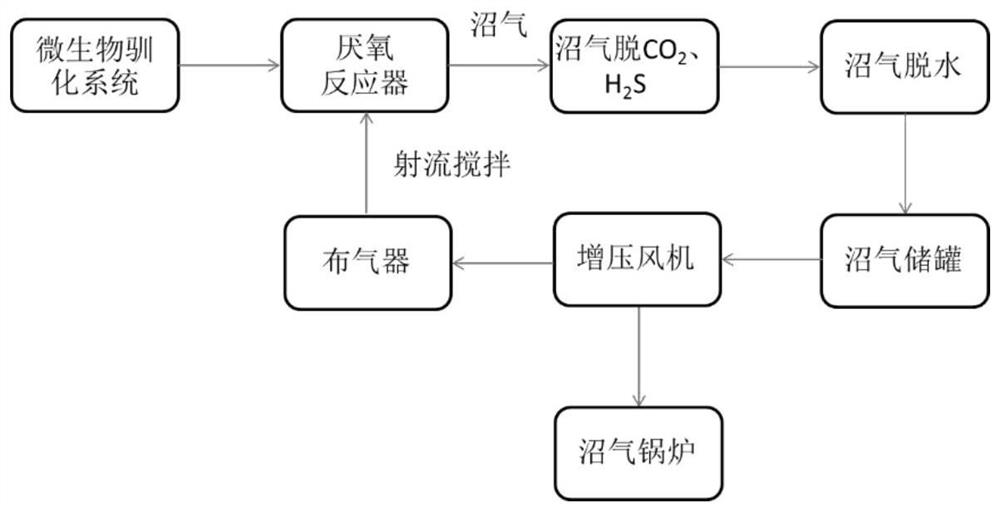

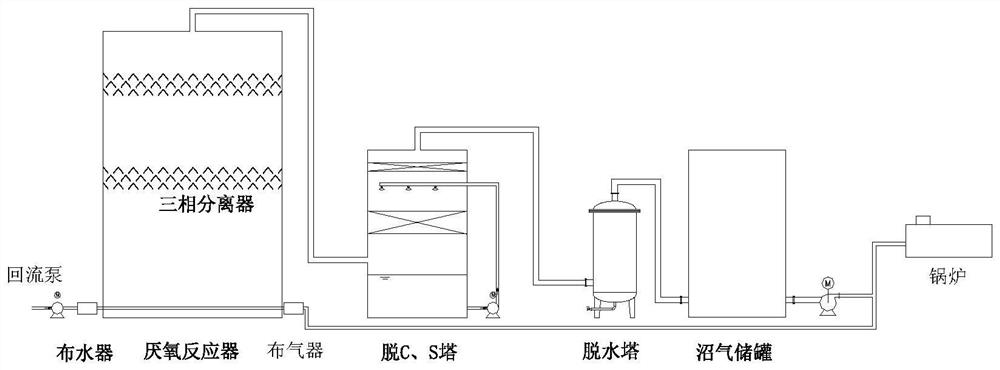

An anaerobic reactor and pharmaceutical wastewater technology, applied in natural water treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of older granular sludge, COD removal rate and methane production , Reduce the COD removal rate and methane production of anaerobic reactors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] In this example, the high-concentration organic wastewater from a certain pharmaceutical factory in Hubei is used as the treatment object. The COD concentration is 10000mg / L, B / C=0.35, the COD of the effluent from the anaerobic reactor is 3000mg / L, and the pH is 5.8.

[0066] A method for improving the treatment efficiency of the anaerobic reactor in the above-mentioned high-concentration organic wastewater treatment process of a certain pharmaceutical factory in Hubei, the steps are as follows:

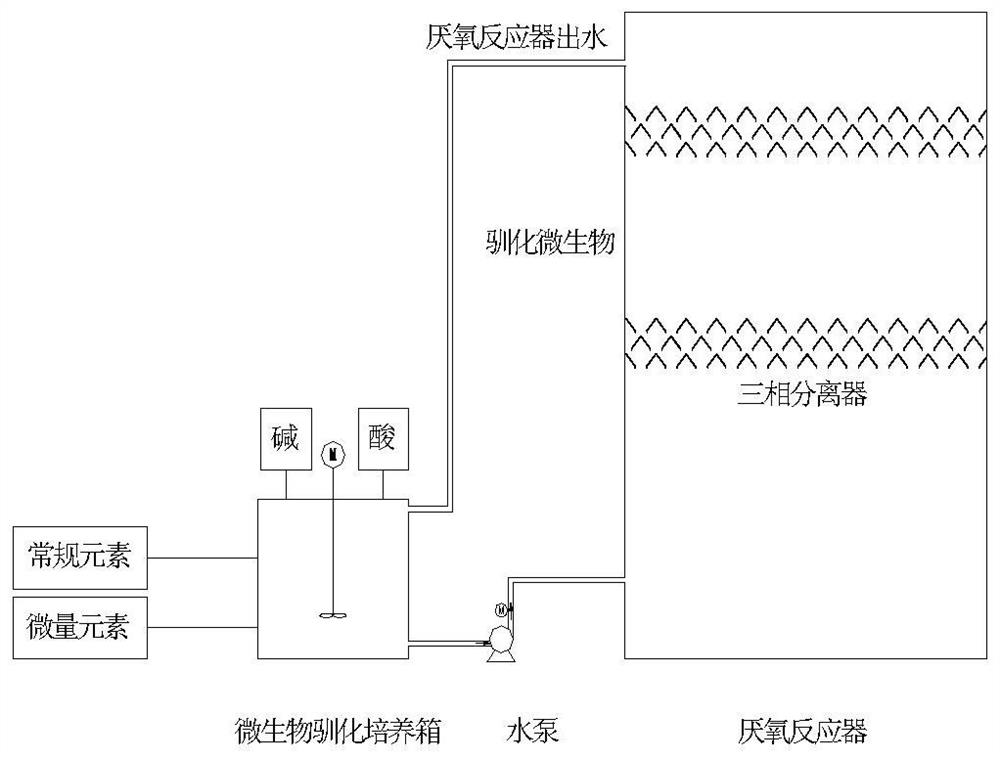

[0067] (1) Microbial domestication system:

[0068] The first microbial acclimatization culture:

[0069] When it is first used, add 55% of its volume anaerobic activated sludge (directly take anaerobic activated sludge from the anaerobic reactor of the original treatment process) in the microbial acclimation incubator, and then supplement the anaerobic reactor effluent to the microorganism 95% of the volume of the acclimatization incubator, add conventional nutrients and mic...

Embodiment 2

[0097] In this example, a high-concentration organic wastewater from a pharmaceutical factory in Hunan is used as the treatment object. The COD concentration is 15000 mg / L, B / C=0.30, the COD of the effluent from the anaerobic reactor is 4530 mg / L, and the pH is 6.2.

[0098] A method for improving the treatment efficiency of the anaerobic reactor in the above-mentioned high-concentration organic wastewater treatment process of a certain pharmaceutical factory in Hunan, the steps are as follows:

[0099] (1) Microbial domestication system:

[0100] The first microbial acclimatization culture:

[0101] When it is first used, add 55% of its volume anaerobic activated sludge (directly take anaerobic activated sludge from the anaerobic reactor of the original treatment process) in the microbial acclimation incubator, and then supplement the anaerobic reactor effluent to the microorganism 95% of the volume of the acclimatization incubator, adding conventional nutrients and micronut...

Embodiment 3

[0107] In this embodiment, high-concentration organic wastewater from a pharmaceutical factory in Guangdong is used as the treatment object, and its COD concentration is 12000 mg / L, and B / C=0.43. The COD of the effluent from the anaerobic reactor is 3670mg / L, and the pH is 6.7.

[0108] A method for improving the treatment efficiency of the anaerobic reactor in the above-mentioned high-concentration organic wastewater treatment process of a pharmaceutical factory in Guangdong, the steps are as follows:

[0109] (1) Microbial domestication system:

[0110] The first microbial acclimatization culture:

[0111] When it is first used, add 55% of its volume anaerobic activated sludge (directly take anaerobic activated sludge from the anaerobic reactor of the original treatment process) in the microbial acclimation incubator, and then supplement the anaerobic reactor effluent to the microorganism 95% of the volume of the acclimatization incubator, add conventional nutrients and mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com