Automatic disc changing, cutting-off and winding mechanism

A winding mechanism and automatic technology, applied in the direction of metal processing, conveying filamentous materials, thin material processing, etc., can solve the problems of wasting manual collection time, affecting the efficiency of equipment coiling tubes, increasing time costs, etc., to avoid collection Volume confusion, simple structure, and the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

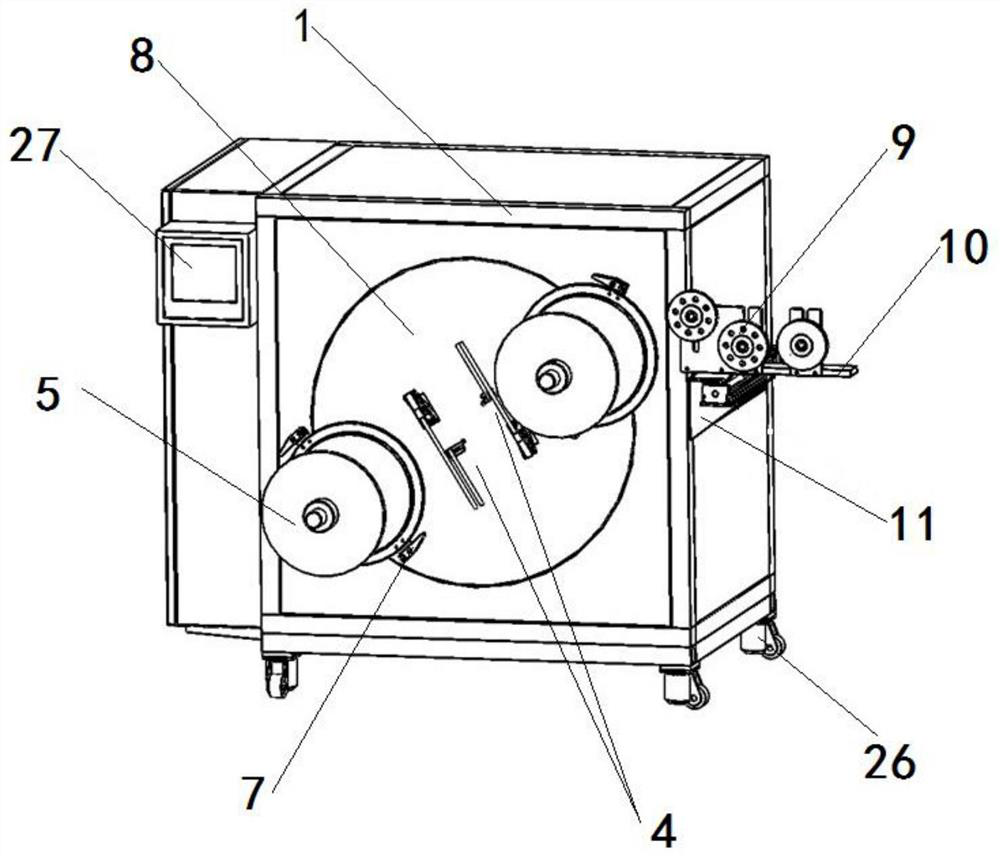

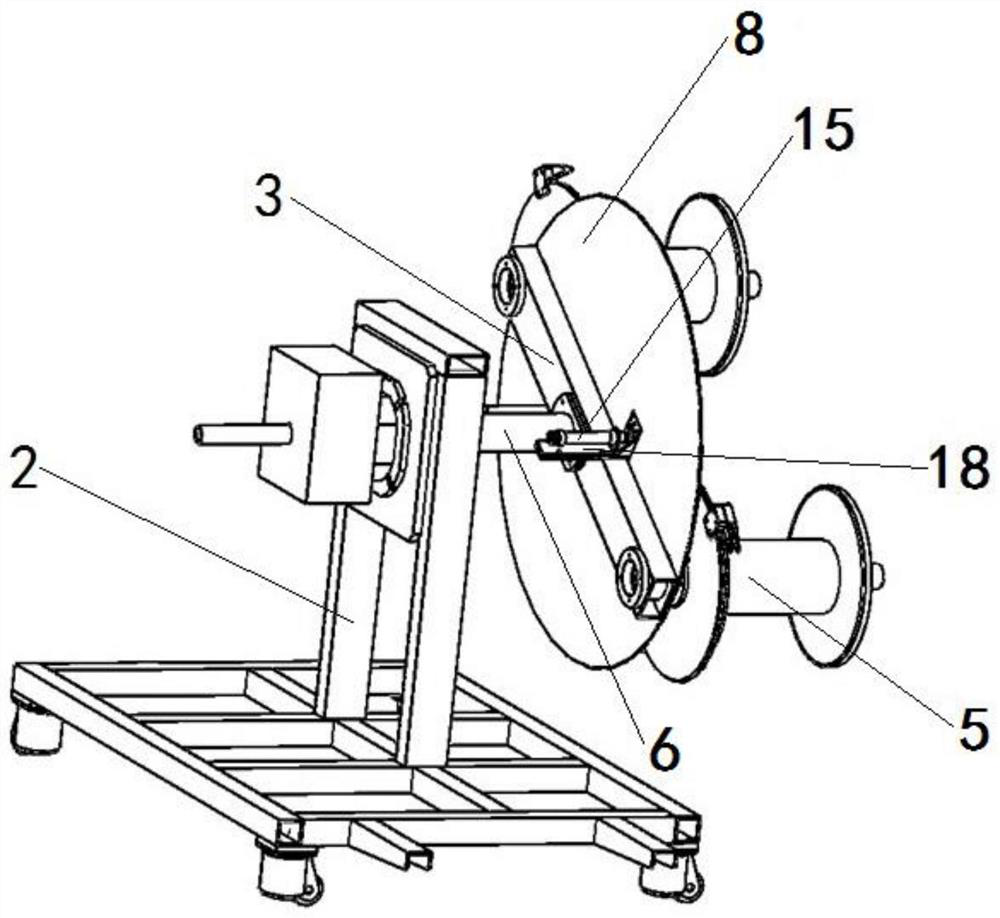

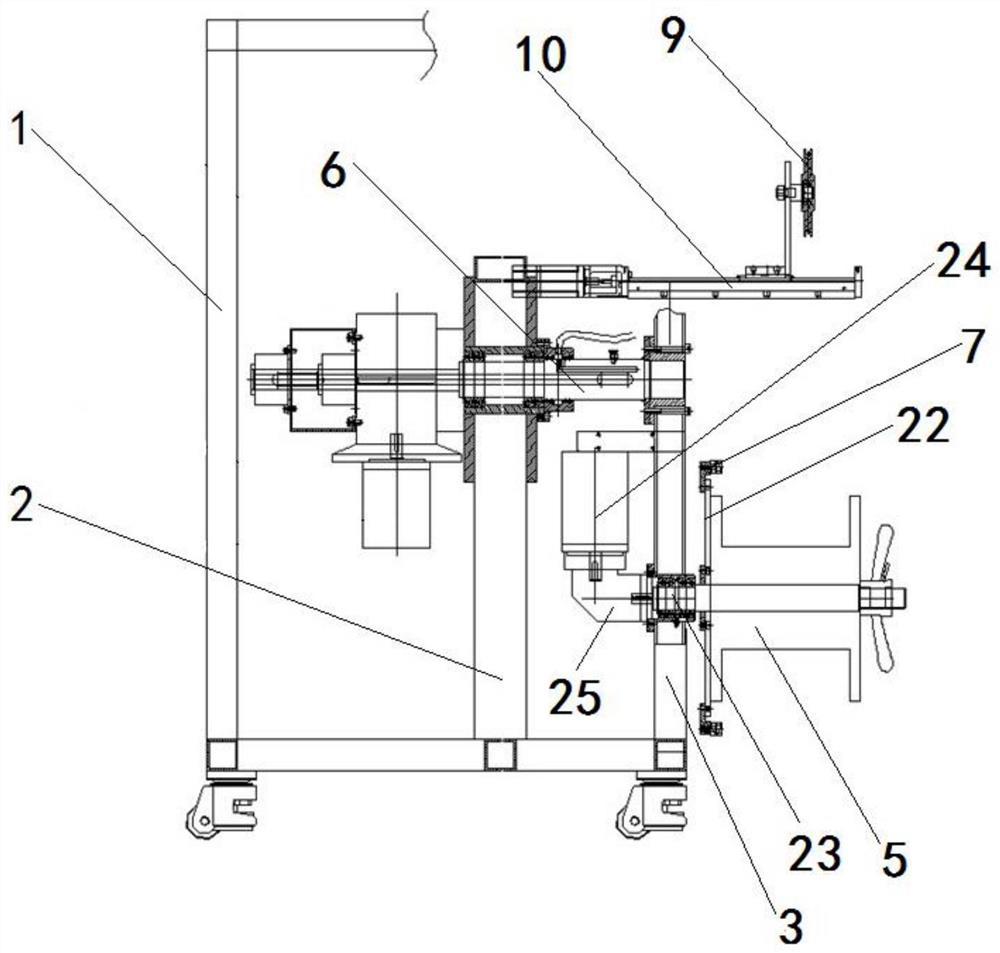

[0025] Such as Figure 1-5 As shown, the present invention specifically discloses an automatic disk changing, cutting and winding mechanism, including a frame 1, a support beam 2, a rotating arm 3, a pipe pulling and cutting device 4 and a winding disk 5, and the support beam 2 is fixed on the frame 1, the upper part of the supporting beam 2 is connected with a rotating shaft 6 through a bearing, and the two ends of the rotating shaft 6 protrude from the supporting beam 2, and one end of the rotating shaft 6 is fixedly connected with the center of the rotating arm 3, and the other end is connected with a driving device; Disc 5 is symmetrically connected to the two ends of rotating arm 3 respectively by bearing, and rotating arm 3 is connected with rotating shaft 2 23 by bearing, and rotating shaft 2 23 two ends stretch out rotating arm 3, and rotating shaft 2 23 one end is fixedly connected with take-up reel 5, and another One end is connected with a precision planetary reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com