Intelligent take-up method

An intelligent, take-up reel technology, applied in thin material handling, conveying filamentous materials, transportation and packaging, etc., can solve the problems of high labor intensity, labor cannot effectively adapt to factory expansion, and labor costs remain high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

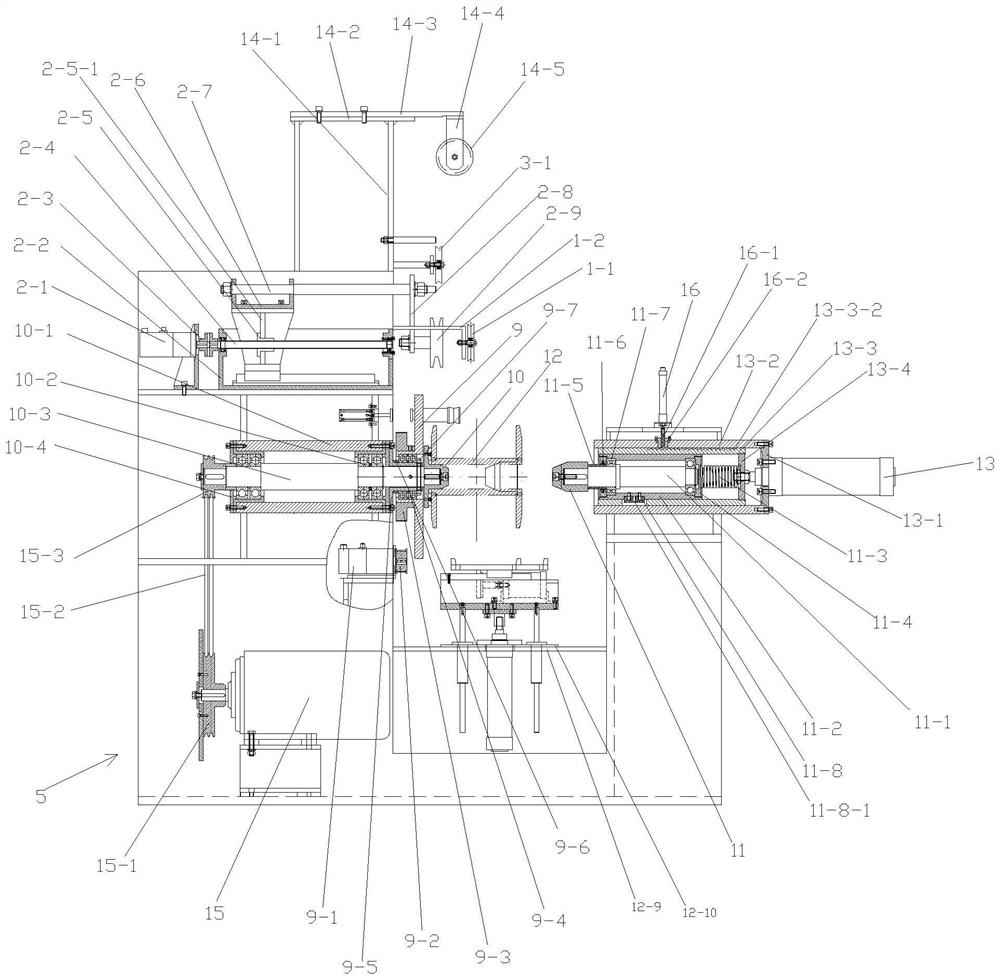

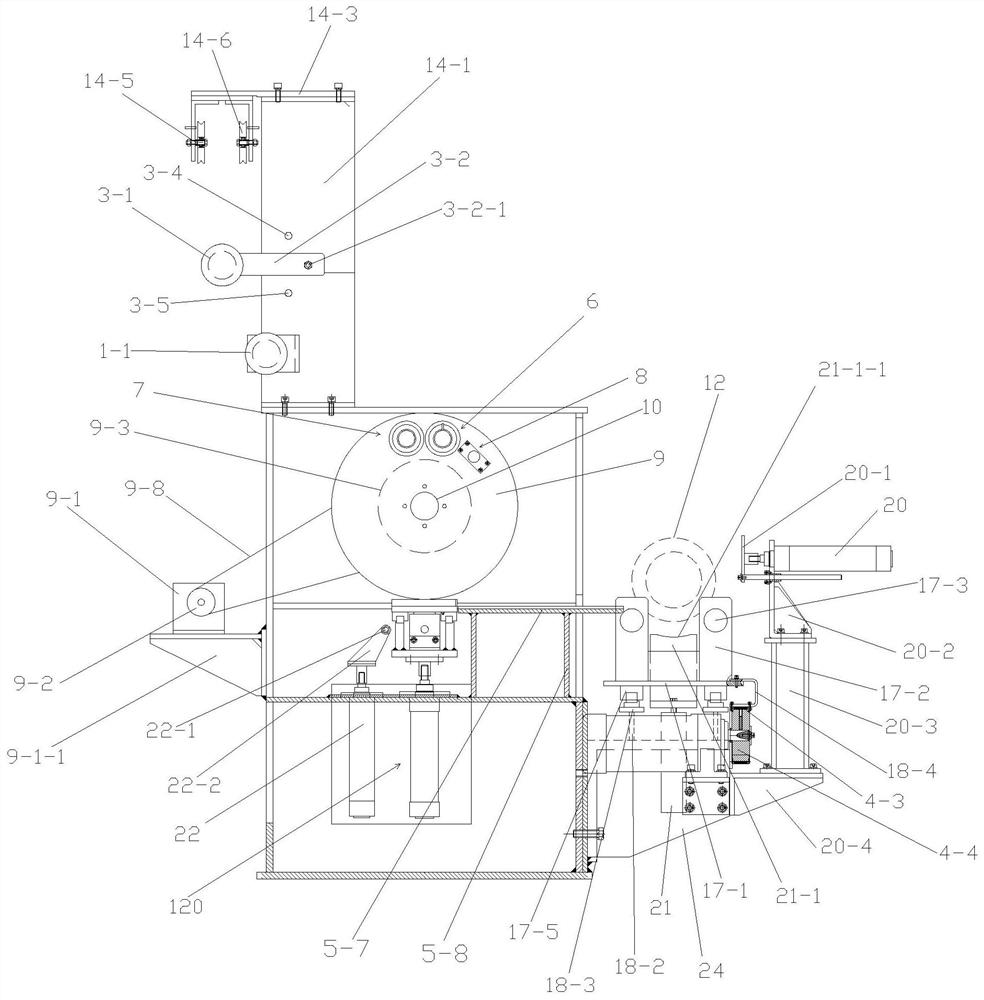

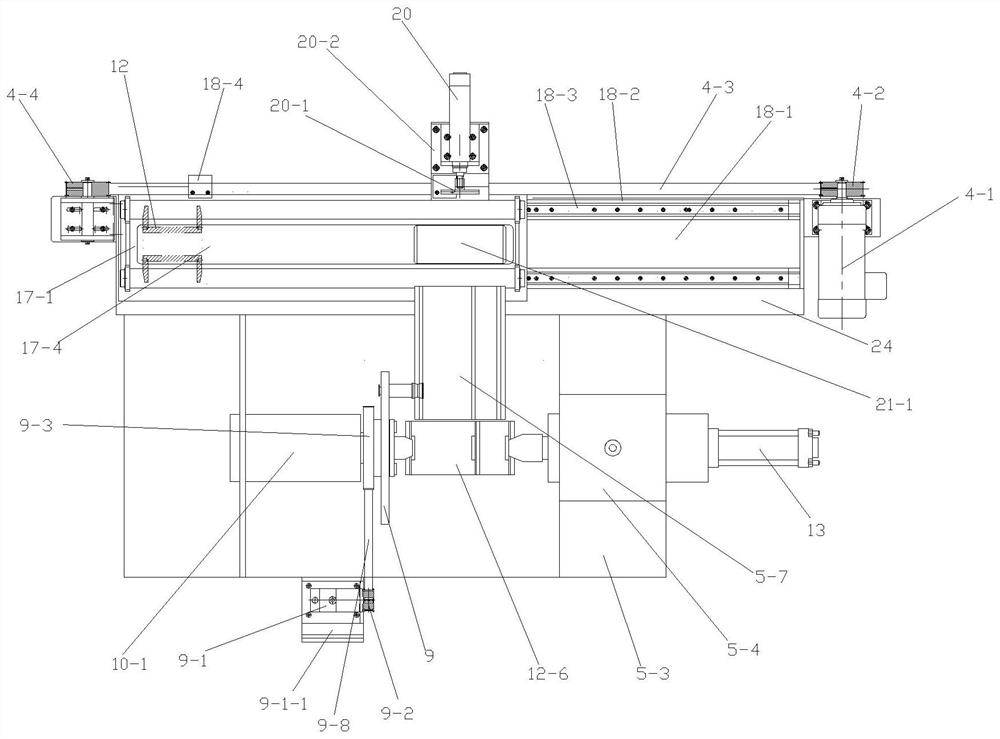

[0145] Such as figure 1 and Figure 14 Shown is a kind of intelligent take-up method, the device that this method adopts comprises frame 5, is arranged on described frame 5 and is provided with the top mechanism that takes-up reel 12 installs and is installed on frame 5 and is positioned at described The wire arrangement mechanism above the top mechanism, and the loading and unloading platform arranged on the frame 5 and positioned at the rear side of the top mechanism, the lifting slide that is arranged on the frame 5 and carries out lifting and horizontal sliding of the take-up reel 12 Moving mechanism 120 and the control module that is arranged on described frame 5;

[0146] The frame 5 includes a base 5-1, a left mount 5-2 disposed on the base 5-1 and a right mount 5-3 disposed on the base 5-1, the left mount 5-2 and the right mounting seat 5-3 are provided with a mounting plate 12-9 for the lifting and sliding mechanism 120 to be installed; Material track 5-7;

[0147...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com