Automatic tool changing and oiling system and automatic tool changing and oiling method

A technology of oil injection and cutting tools, applied in electric/hybrid power, maintenance and safety accessories, comprehensive factory control, etc., can solve problems such as product quality impact, error prone, high cost, etc., to save manpower and material resources, ensure stability, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

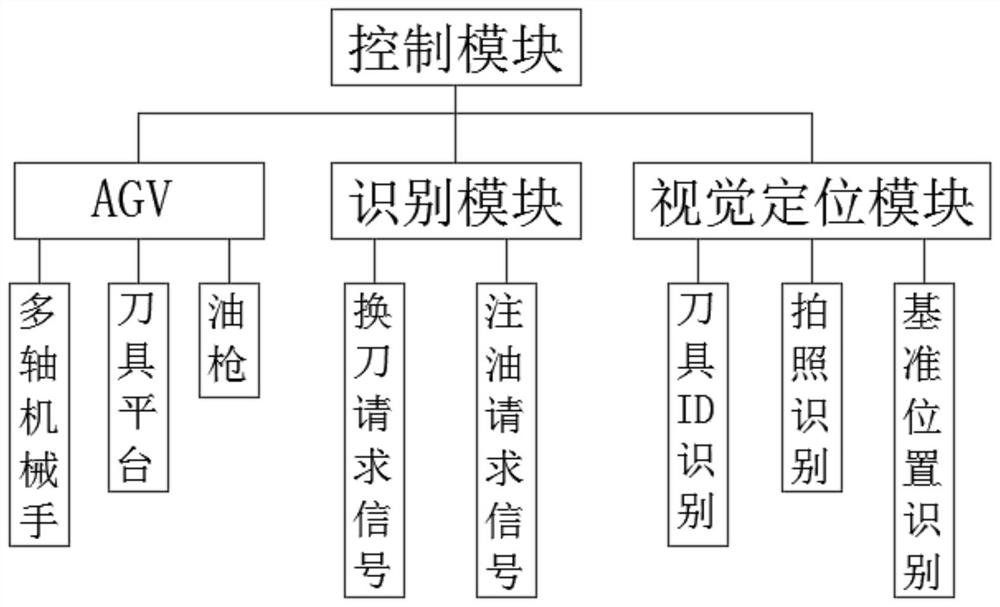

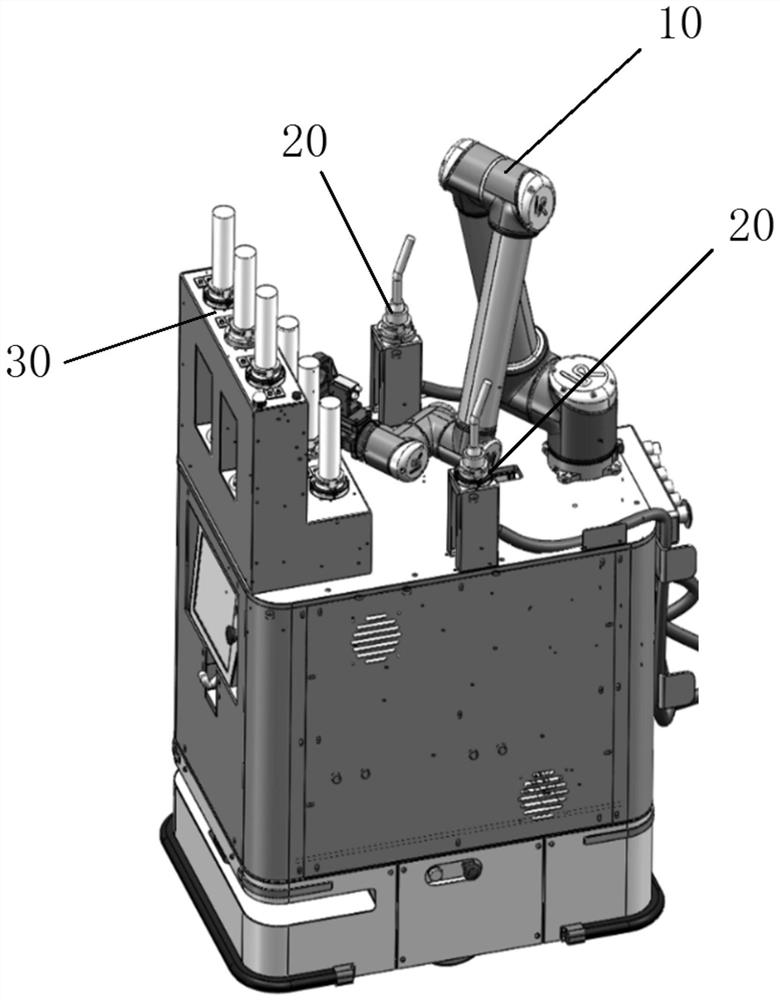

[0048] The present invention provides an automatic tool changing and oiling system utilizing an AGV as a vehicle, such as figure 1 As shown in -7, it is used for automatic tool change or oil filling operation according to the signal source station, including AGV, identification module, visual positioning module and control module.

[0049] Among them, the identification module can communicate with the on-site machining center to obtain production-related information, and then identify the source of the tool change and / or oil injection signal,

[0050] The AGV is equipped with a multi-axis manipulator 10, an oil gun 20 and a tool platform 30;

[0051] The control module can obtain information such as the real-time route information of the AGV, the working status of the multi-axis manipulator 10, the amount of oil storage, etc., and convert the above information into corresponding instructions to provide control signals.

[0052]The specific identification module communicates w...

Embodiment 2

[0074] This embodiment provides an automatic tool changing and oiling method, which is realized by using the automatic tool changing and oiling system in Embodiment 1, including:

[0075] Obtain the source station of the tool change or oil injection signal through the identification module, and the identification module sends the first command and the second command to the control module;

[0076] The control module sets the running path of the AGV according to the first instruction, and controls the AGV to reach the corresponding source station;

[0077] The control module controls the multi-axis manipulator on the AGV to perform tool change or oil injection according to the second instruction, wherein the tool change operation and oil injection operation can be carried out alternately and cooperatively, such as Figure 8 shown.

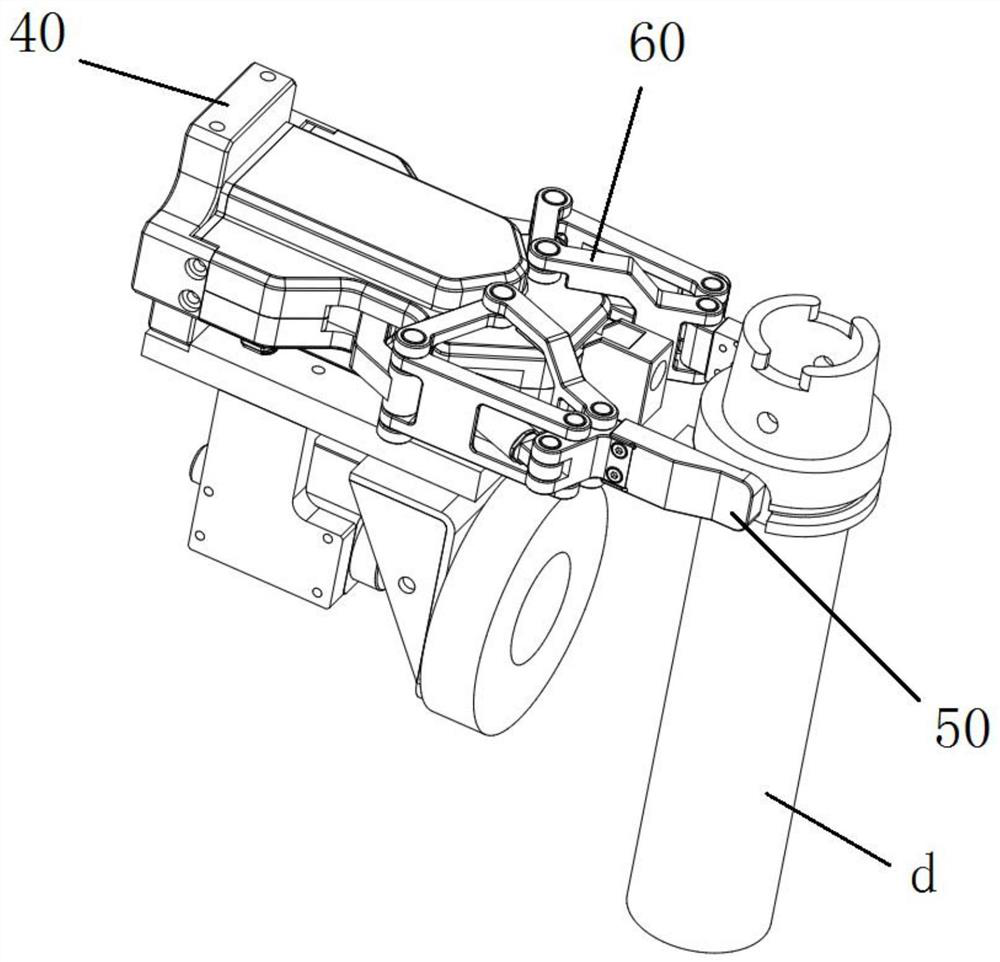

[0078] The tool change operation is as follows: after the three-dimensional coordinates of the tool are determined by the visual positioning modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com