Electron beam welding method for lock-bottom-free film disc type part

A technology of electron beam welding and membrane disk, which is applied in the direction of electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of increasing the deformation of parts after welding, unreserved processing allowance, unqualified parts size, etc. To achieve the effect of controlling welding deformation, effectively controlling welding deformation and good weld seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further describe the content of the present invention in detail, the content of the present invention will be further described below in conjunction with the accompanying drawings.

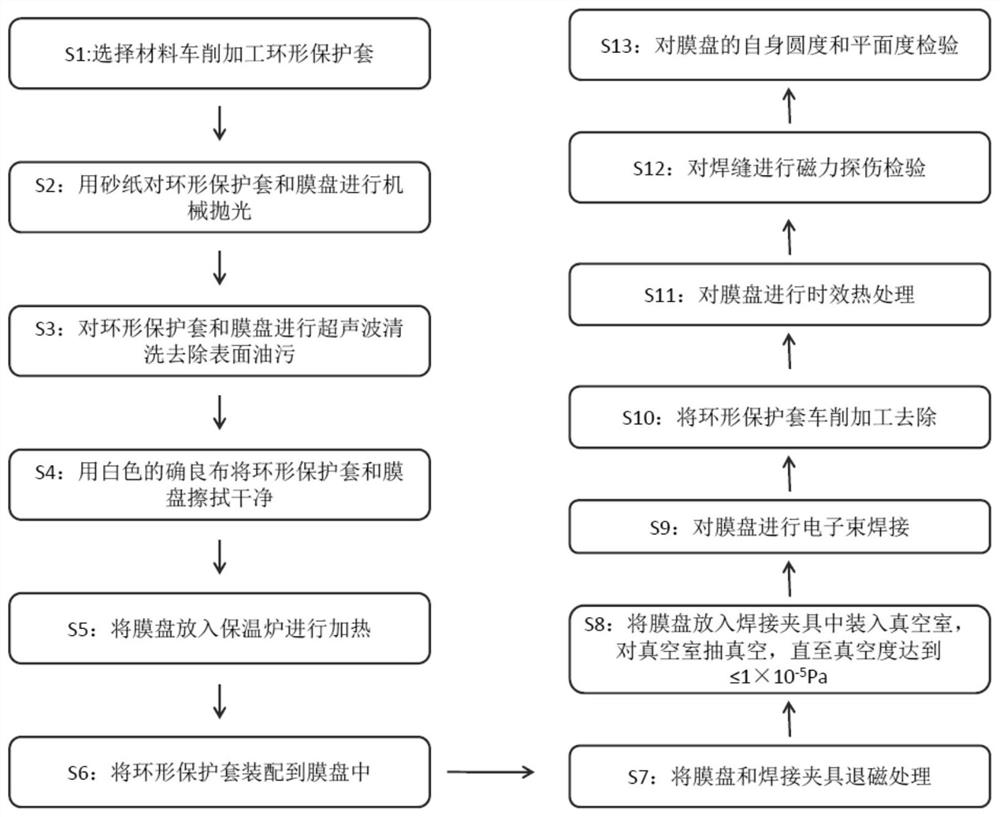

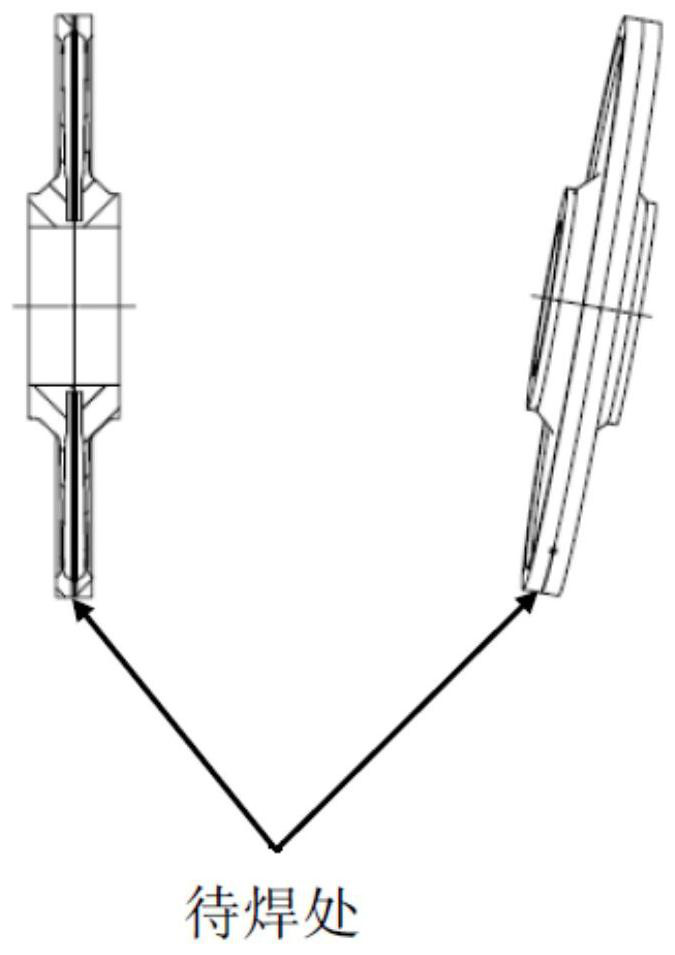

[0036] Such as figure 1 Shown, a kind of electron beam welding method of disc-like parts without bottom-lock film, comprises the following steps:

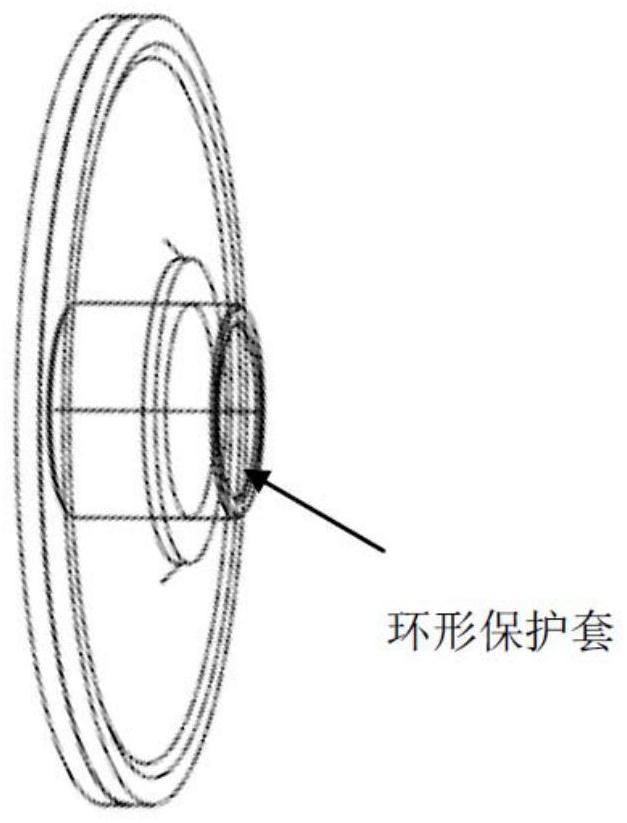

[0037] S1: Select the same material as that of the non-lock bottom film disc to be welded and process a ring-shaped protective sleeve, such as image 3 As shown, the outer diameter of the annular protective sleeve is an interference fit with the central through hole of the non-lock bottom film disc to be welded, and there is a through hole in the center of the annular protective sleeve; the width of the annular protective sleeve is 2mm-3mm; The height of the annular protective sleeve is 0.5mm-1mm higher than that of the non-lock bottom membrane disc to be welded;

[0038] S2: Use 800-mesh sandpaper to mechanically polish the ring-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com