Dual-performance turbine disc and preparation method thereof

A turbine disk and dual-performance technology, which is applied in the direction of turbines, manufacturing tools, mechanical equipment, etc., can solve the problems of hindering crack growth, different heat treatment systems, and different solution temperatures, so as to reduce weight, increase thrust-to-weight ratio, and optimize design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A method for preparing a dual-performance turbine disk, comprising the steps of:

[0046] (a) Carrying out hot isostatic pressing to the hub alloy powder and the rim alloy powder respectively to obtain the hub disc blank and the rim ring;

[0047] (b) Assembling the hub disk blank and the wheel rim ring, and performing hot isostatic pressure diffusion bonding to obtain a double alloy disk blank;

[0048] (c) heat-treating the bialloy disk blank;

[0049] The hub alloy powder is mainly composed of the following components by mass percentage: C 0.02%-0.09%, Co 7.0%-9.5%, Cr 11.2%-14.0%, W 2.5%-4.2%, Mo 2.4%-4.1% %, Al 2.6%~4.3%, Ti 1.8%~3.0%, Nb 2.6%~4.3%, and the balance Ni;

[0050] The rim alloy powder is mainly composed of the following components by mass percentage: C 0.01%-0.06%, Co 10.5%-15.0%, Cr 14.5%-18.2%, W 2.8%-4.5%, Mo 3.0%- 5.1%, Al 1.8%-3.3%, Ti 2.5%-4.5%, Nb 0.3%-1.1%, and the balance Ni.

[0051] The present invention adopts specific wheel hub alloy ...

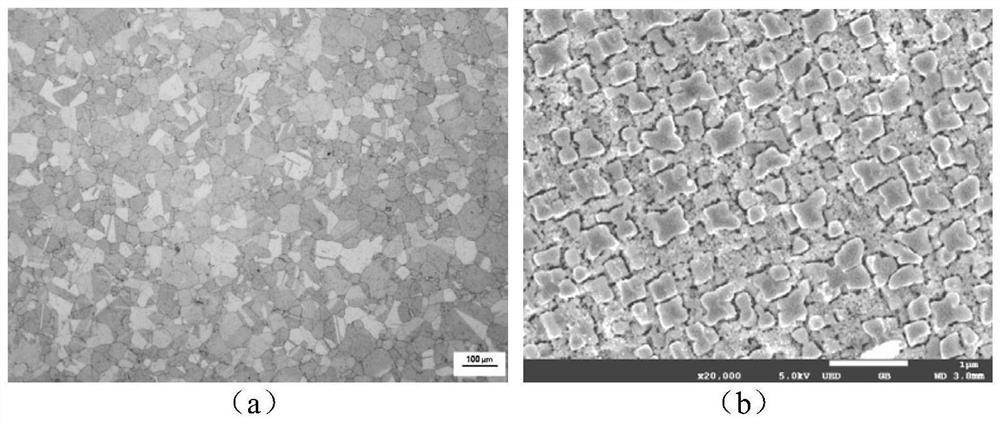

Embodiment 1

[0078] This embodiment provides a method for preparing a dual-performance turbine disk, including the following steps:

[0079] (1) The hub is made of FGH4095 alloy, the main chemical composition (by mass percentage) is: Co 8.0%, Cr13.2%, W 3.4%, Mo 3.5%, Al 3.4%, Ti 2.5%, Nb 3.4%, C 0.06 %, Ni balance; the conventional plasma rotating electrode method (PREP) is used to prepare FGH4095 alloy powder, and the particle size of the powder is 50-150 μm.

[0080] The rim is made of FGH4096 alloy, the main chemical composition (by mass percentage) is: Co 13.1%, Cr 16.2%, W 3.9%, Mo 4.0%, Al 2.3%, Ti 3.6%, Nb 0.7%, C 0.03%, Ni balance: the powder is prepared by the conventional plasma rotating electrode method (PREP), and the particle size of the powder is 50-150 μm.

[0081] (2) FGH4095 alloy powder with a particle size of 50-150 μm was put into a carbon steel sheath for simulation experiments, and the sheath after the powder was filled was formed by hot isostatic pressing. Pressur...

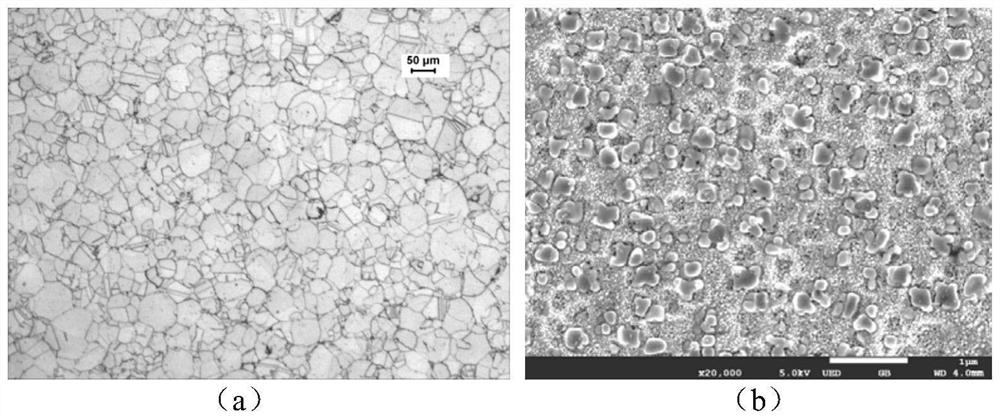

Embodiment 2

[0086] This embodiment provides a method for preparing a dual-performance turbine disk, including the following steps:

[0087] (1) The hub is made of FGH4095 alloy, the main chemical composition (by mass percentage) is: Co 8.0%, Cr13.2%, W 3.4%, Mo 3.5%, Al 3.4%, Ti 2.5%, Nb 3.4%, C 0.06 %, Ni balance; the conventional plasma rotating electrode method (PREP) is used to prepare FGH4095 alloy powder, and the particle size of the powder is 50-150 μm.

[0088] The rim is made of FGH4096 alloy, the main chemical composition (by mass percentage) is: Co 13.1%, Cr 16.2%, W 3.9%, Mo 4.0%, Al 2.3%, Ti 3.6%, Nb 0.7%, C 0.03%, Ni balance: the powder is prepared by the conventional plasma rotating electrode method (PREP), and the particle size of the powder is 50-150 μm.

[0089] (2) Put the FGH4095 alloy powder with a particle size of 50-150 μm and the FGH4096 alloy powder with a particle size of 50-150 μm into carbon steel sheaths (corresponding to filling in the hub area and rim area ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com